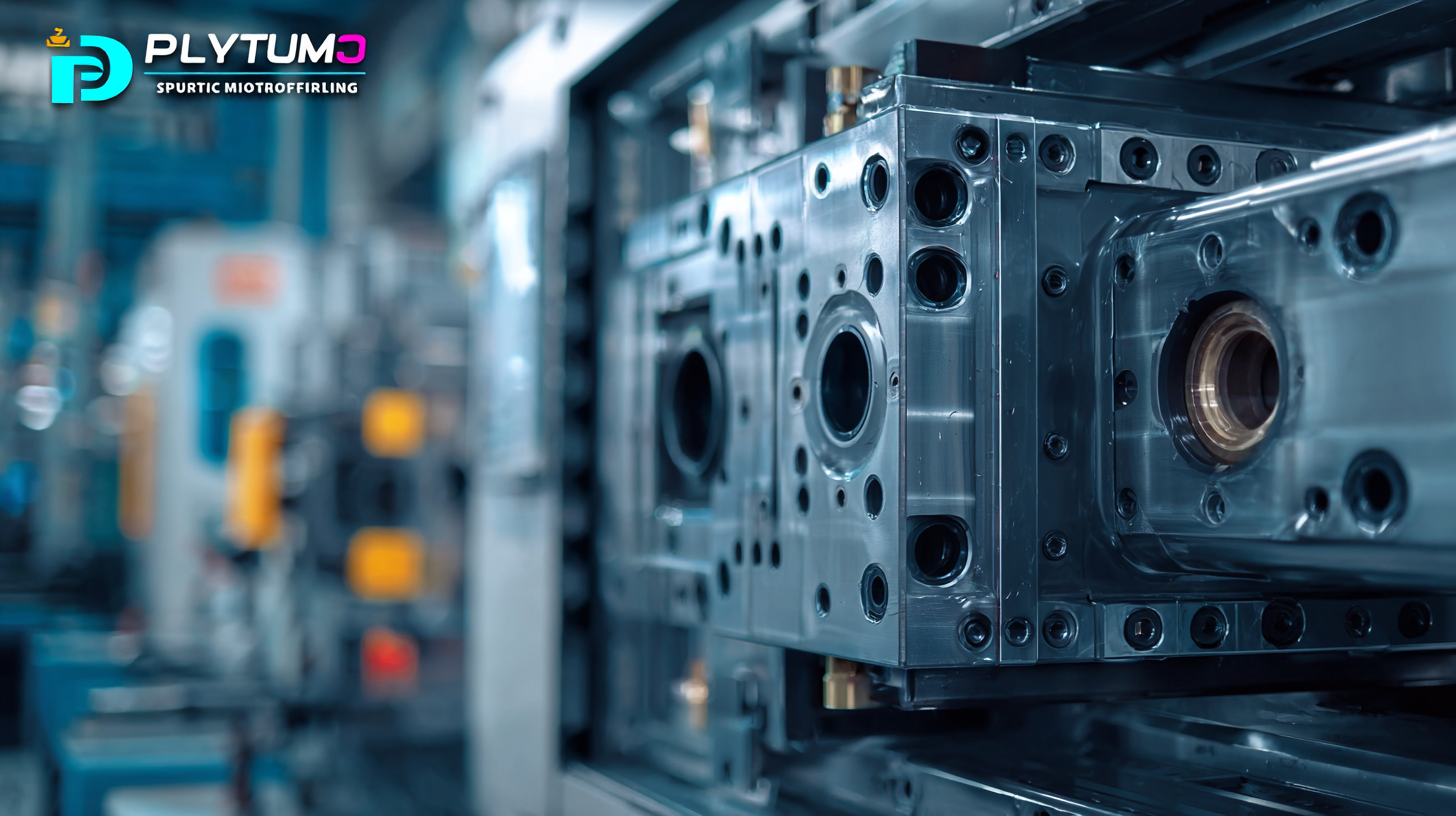

In today's competitive manufacturing landscape, Plastic Injection Molding Services have emerged as a pivotal method for producing high-quality components efficiently. According to a report by Grand View Research, the global injection molding market is projected to reach USD 341.1 billion by 2025, driven by the increasing demand for precision-engineered parts across various industries, including automotive, consumer goods, and electronics.

The advantages of utilizing these services are manifold, encompassing reduced production time, improved product consistency, and the ability to create complex geometries that traditional manufacturing processes struggle to achieve.

Additionally, a study by MarketsandMarkets indicates that advancements in material technology and automation are further enhancing the capabilities of plastic injection molding, making it a go-to solution for manufacturers seeking reliable and high-quality outputs.

As businesses increasingly turn to trusted sources for their manufacturing needs, the reputation of Chinese manufacturers for delivering uniform quality at competitive prices remains a significant factor in global procurement strategies.

When it comes to manufacturing, cost efficiency is a primary concern for businesses seeking the best plastic injection molding services. This process is renowned for its ability to produce high-quality parts with automation, which significantly reduces labor costs. Companies can benefit from large production runs that minimize the cost per unit, allowing them to allocate their budgets more effectively. This reduction in costs is instrumental for startups and small businesses, enabling them to compete with larger firms without compromising on quality.

Furthermore, the efficiency of plastic injection molding contributes to resource savings, as the process generates minimal waste. High precision in design means that more products are produced from less material, leading to reduced raw material costs. Additionally, the rapid prototyping capabilities allow companies to test designs quickly and economically, enhancing their ability to innovate while keeping production costs manageable. Ultimately, choosing quality plastic injection molding services can lead to substantial financial benefits throughout the product lifecycle, from production to market.

Advancements in molding techniques have significantly enhanced product quality, as evidenced by the recent patent applications by innovative companies. For instance, a firm specializing in plastic components has developed advanced injection molding equipment and methods specifically for the production of clothing fasteners. This initiative highlights the industry's commitment to enhancing both product quality and manufacturing efficiency. By implementing cutting-edge technology, manufacturers can ensure that the final products meet higher standards for durability and precision.

Moreover, the broader context of the molding industry indicates a robust growth outlook. As manufacturers increasingly adopt innovative strategies, the overall quality of molded products continues to improve, which in turn bolsters consumer confidence and satisfaction. The ongoing development in materials and techniques allows for greater customization, better surface finishes, and enhanced functionality in a wide array of products. Companies that embrace these advancements position themselves favorably in a competitive marketplace, benefiting from higher-quality offerings that meet evolving customer needs.

The fast-paced nature of modern manufacturing requires solutions that not only meet quality standards but also enhance efficiency. Expert plastic injection molding services epitomize this need, significantly reducing production time while maintaining high-quality outcomes. According to a report by the American Society of Mechanical Engineers (ASME), utilizing specialized injection molding services can cut lead times by up to 30% compared to in-house production methods. This rapid turnaround is especially crucial in industries such as automotive and consumer electronics, where market demands can rapidly shift.

Furthermore, expert services bring with them cutting-edge technology and skilled personnel who are adept at optimizing the molding process. Industry analysis from the Plastics Industry Association indicates that leveraging advanced mold design and simulation software can decrease cycle times by approximately 20%. This efficiency not only accelerates production but also enables companies to respond swiftly to customer needs, thereby enhancing overall competitiveness. By investing in the best plastic injection molding services, companies are not just saving time—they are positioning themselves as agile, innovative players in their respective markets.

| Advantage | Description | Estimated Time Savings (%) |

|---|---|---|

| Expert Knowledge | Utilizing experienced professionals ensures efficient design and optimization, reducing the need for rework. | 30% |

| Advanced Technology | Access to the latest machinery and technology increases production speed and quality. | 25% |

| Material Efficiency | Professionals can select the right materials to minimize waste and enhance functionality. | 20% |

| Streamlined Processes | Implementing proven workflows reduces delays and accelerates production timelines. | 35% |

| Quality Control | Rigorous quality assurance practices minimize defects and rejections, saving time in the long run. | 15% |

In today's competitive manufacturing landscape, customization is crucial for meeting specific market demands. Top plastic mold specialists offer a range of customization opportunities that allow businesses to develop unique products tailored to their exact requirements. According to a report by the Plastic Industry Association, approximately 70% of manufacturers leverage customized solutions to enhance product functionality and marketability. These specialists utilize advanced technologies and materials to provide bespoke designs, ensuring that companies can differentiate themselves in the marketplace.

When considering plastic injection molding services, it’s essential to assess the customization potential. Different types of molds, such as multi-cavity molds and family molds, can affect production efficiency and cost-effectiveness. For instance, multi-cavity molds can produce several parts simultaneously, significantly increasing output. As highlighted in a study by the Association for Manufacturing Technology, utilizing advanced mold technologies can reduce production lead times by up to 30%.

Tip: Always communicate your specific requirements and limitations clearly when working with mold specialists. This ensures the design aligns perfectly with production capabilities. Furthermore, consider requesting prototypes to visualize the final product before committing to full-scale production. This step can save time and resources, making the customization process smoother and more efficient.

Sustainability has become a significant focus in modern manufacturing processes, and plastic injection molding is no exception. With the increasing awareness of environmental issues, the best plastic injection molding services have integrated sustainable practices into their operations. This includes using recycled materials and bio-based plastics, greatly reducing the reliance on virgin resources. By employing these eco-friendly materials, manufacturers can minimize their carbon footprint and contribute to a circular economy, where plastic is reused rather than discarded.

Moreover, advancements in technology have allowed for more efficient production methods that reduce waste and energy consumption. Techniques such as mold temperature control, optimized cycle times, and energy-efficient machinery not only enhance productivity but also lower the overall environmental impact. Many leading plastic injection molding companies are adopting practices like closed-loop water systems and energy recovery systems, which further bolster their commitment to sustainability. By prioritizing these practices, they not only meet the growing demand for green solutions but also position themselves as responsible industry leaders.