In the rapidly evolving automotive industry, the demand for efficient manufacturing processes has never been more pressing. One such process that has garnered significant attention is Automotive Injection Molding. This technique not only enhances production speed but also improves the precision of the components used in vehicles. As noted by industry expert Dr. Emily Carter, "Automotive Injection Molding is transforming the way we think about vehicle design and manufacturing, allowing for greater innovation and efficiency."

Automotive Injection Molding offers multiple benefits that extend beyond simple cost savings. It allows manufacturers to create complex geometries that would be difficult, if not impossible, to achieve with traditional manufacturing methods. This capability is essential as demand for lightweight, fuel-efficient vehicles continues to rise. Dr. Carter further emphasizes that "the versatility and adaptability of Automotive Injection Molding make it indispensable for meeting the modern challenges of automotive production."

As the automotive landscape shifts towards smarter, more sustainable solutions, the role of Automotive Injection Molding becomes increasingly critical. Embracing this technology not only supports manufacturers in staying competitive but also fosters a culture of innovation that is essential for long-term success in the industry.

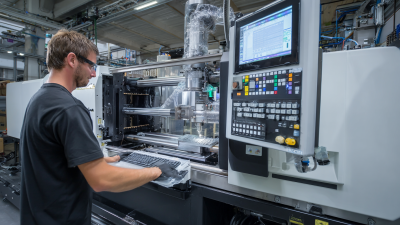

Automotive injection molding is a manufacturing process widely used in the automotive industry to produce a variety of components and parts with precision and efficiency. This technique involves injecting molten plastic into a specially designed mold, where it cools and solidifies into a specific shape. The method not only supports complex geometries but also allows for high-volume production, making it an ideal choice for creating parts such as dashboard components, exterior panels, and various internal fittings.

One of the primary advantages of automotive injection molding is its cost-effectiveness, particularly for large-scale production runs. The initial setup of molds can be expensive, but once established, the process provides consistent quality and reduces per-part production costs significantly. Additionally, it supports the use of lightweight materials, which is crucial in the automotive sector for improving fuel efficiency and performance. Enhanced design flexibility also allows manufacturers to innovate and adapt components rapidly, ensuring they keep pace with evolving consumer demands and regulatory standards.

| Aspect | Description | Benefits |

|---|---|---|

| Definition | Automotive injection molding is a manufacturing process used to produce parts by injecting molten material into a mold. | High precision and repeatability in parts production. |

| Materials Used | Commonly utilizes thermoplastics, thermosets, and elastomers. | Wide variety of materials allows for diverse application needs. |

| Production Speed | High-speed production with short cycle times. | Increased efficiency and lower operational costs. |

| Cost Efficiency | Initial setup cost is high, but mass production reduces per-unit cost. | Cost-effective for large volume production runs. |

| Design Flexibility | Allows for complex shapes and integrated components. | Reduces the need for assembly and additional part handling. |

| Applications | Used for various automotive parts such as dashboards, panels, and conduits. | Versatile use across multiple automotive systems. |

Automotive injection molding is a highly efficient manufacturing process used to create precise components for vehicles. This method involves the injection of molten plastic into a mold, where it cools and solidifies, forming intricate parts with high durability and dimensional accuracy. The first step in this process is the design of the mold, which is meticulously crafted to meet specific specifications. Once the mold is ready, it is heated, and the plastic material is injected under pressure, allowing for a quick and uniform shaping of the component. After cooling, the finished parts are ejected and undergo quality checks before being assembled into the vehicle.

Tips: When designing molds for automotive parts, consider factors such as heat distribution and material flow to ensure efficient production and high-quality outputs. Additionally, investing in advanced technology can streamline the injection molding process, reducing cycle times and waste.

Automotive injection molding not only offers precision but also flexibility in design, enabling manufacturers to produce complex geometries that would be challenging with other methods. Furthermore, the scalability of this approach allows for cost-effective production runs, whether for small batches or large-scale manufacturing. The sustainability aspect is also noteworthy, as modern injection molding processes often utilize recyclable materials, contributing to the industry's move towards greener practices.

Tips: Regular maintenance and monitoring of injection molding machines can prevent breakdowns and maximize productivity. Training staff on best practices in handling materials will further enhance the quality of the finished products.

Automotive injection molding is a crucial process in the manufacturing of various components within vehicles, relying heavily on a selection of materials that ensure durability, weight efficiency, and cost-effectiveness. One of the primary materials used is thermoplastic polymers, particularly polypropylene and polyamide. These materials are favored for their excellent mechanical properties, resistance to heat, and ability to be easily molded into complex shapes. The lightweight nature of these polymers also contributes to overall vehicle efficiency, leading to better fuel economy and lower emissions.

Another key material in automotive injection molding is thermosetting plastics, such as epoxy resins and phenolic resins. These materials are known for their exceptional strength and thermal stability, making them suitable for high-performance applications in automotive parts. They also offer superior chemical resistance, which is critical for components exposed to harsh conditions, such as engine parts or under-hood applications. Additionally, the use of reinforcements, such as glass fibers, can enhance the properties of these materials, providing further strength and rigidity to molded components. Together, these materials play a vital role in creating robust and resilient automotive parts, driving innovation and efficiency in the industry.

Injection molding is a manufacturing process widely utilized in the automotive industry for producing high-quality plastic parts.

One of its primary benefits is the ability to create complex shapes with precision and consistency, which is crucial in the automotive sector where components must fit seamlessly together. This method allows manufacturers to produce intricate designs that would be difficult or impossible to achieve with traditional machining processes.

Another significant advantage of injection molding in automotive production is its efficiency and scalability. Once the initial mold is created, the process can produce large volumes of parts in a relatively short time, significantly reducing manufacturing lead times.

Additionally, the material waste is minimal compared to other manufacturing techniques, making it a more sustainable option. This efficiency not only lowers production costs but also enhances the overall competitiveness of automotive manufacturers in the market, allowing them to respond quickly to changing consumer demands.

Overall, injection molding plays a vital role in streamlining production processes in the automotive industry while ensuring high-quality output.

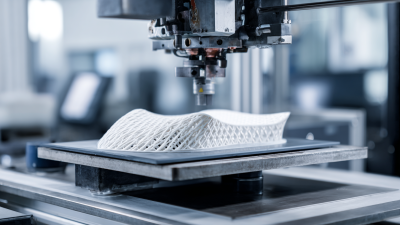

The automotive industry is experiencing a transformative shift, with injection molding technology leading the charge. One of the future trends in this field is the integration of advanced materials that enhance the durability and performance of automotive components. Biodegradable plastics and lightweight composites are becoming increasingly prevalent, driven by consumer demand for sustainability and efficiency. These materials not only reduce the vehicle’s weight, contributing to better fuel efficiency, but also minimize environmental impact, aligning with global trends towards eco-friendliness.

Another significant trend is the adoption of automation and smart manufacturing processes within injection molding operations. The implementation of artificial intelligence and machine learning is enabling manufacturers to predict failures, optimize production cycles, and achieve higher precision in part design. This transition not only streamlines production efficiency but also reduces waste, ultimately lowering costs. As the automotive sector moves towards more complex designs and greater customization, the evolution of injection molding technology will play a crucial role in meeting these demands and driving the industry forward.