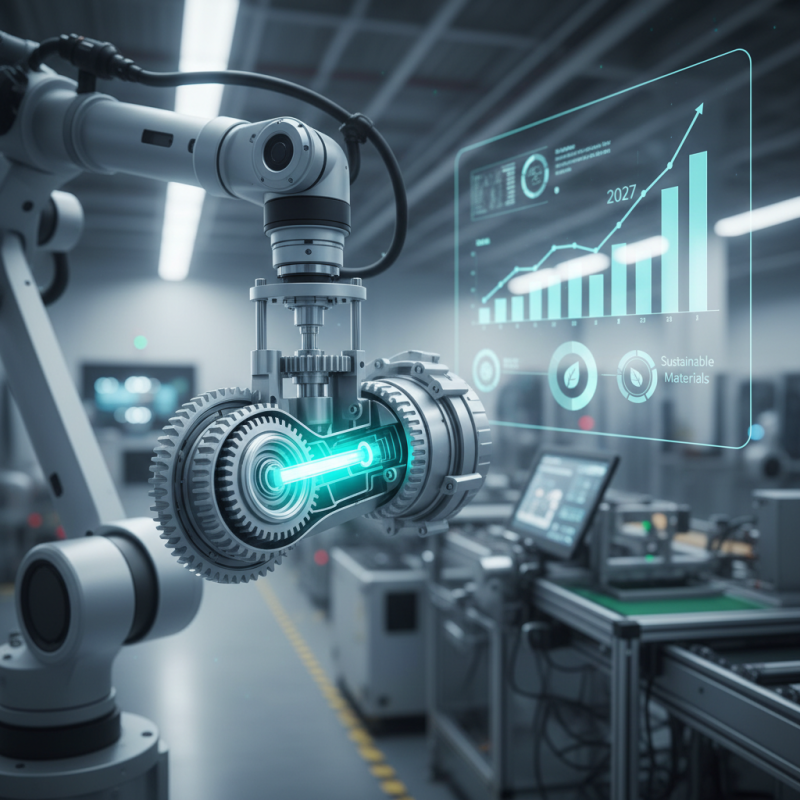

The automotive industry is rapidly evolving, with a focus on efficiency and innovation. Custom Automotive Plastic Injection Molding plays a critical role in this transformation. According to a recent report, the global automotive plastic market is set to reach $42 billion by 2027. This growth reflects the increasing demand for lightweight and durable materials in vehicle design.

With custom molding, manufacturers can create intricate parts that meet specific performance needs. This method allows for the production of complex shapes with high precision. Reports indicate that 80% of automotive engineers prefer custom molded parts for their flexibility and reliability. However, challenges remain. Ensuring consistent quality and managing production costs requires careful planning and execution.

Introducing innovations in Custom Automotive Plastic Injection Molding can significantly enhance vehicle performance. Yet, the industry must also confront issues like environmental impacts. Sustainable materials are becoming a priority. The shift towards eco-friendly practices should not compromise quality. Thus, balancing these aspects is essential for future advancements.

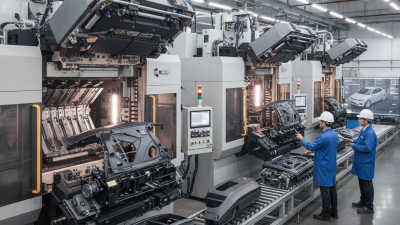

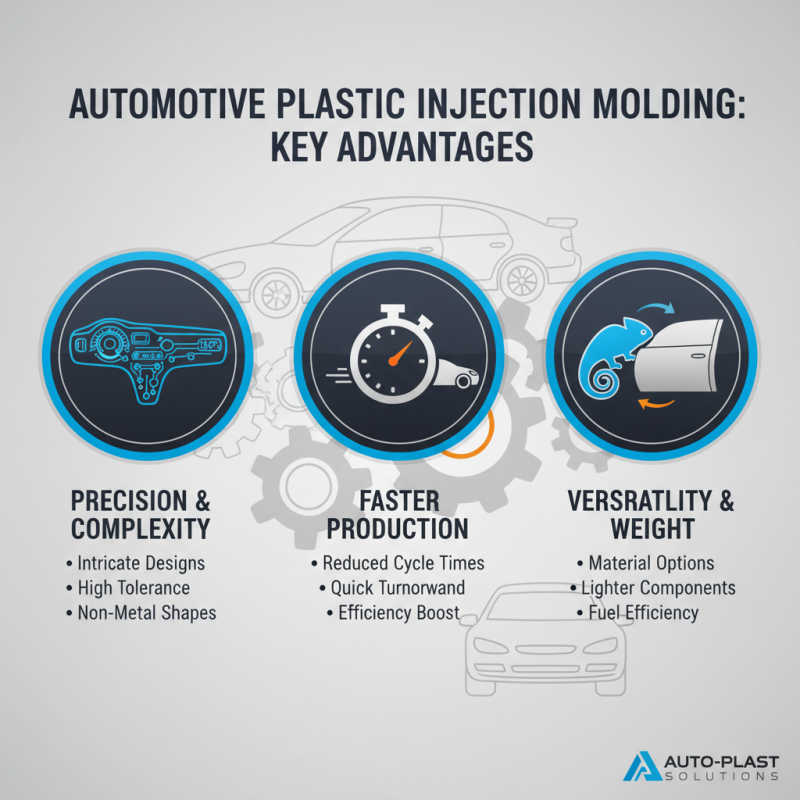

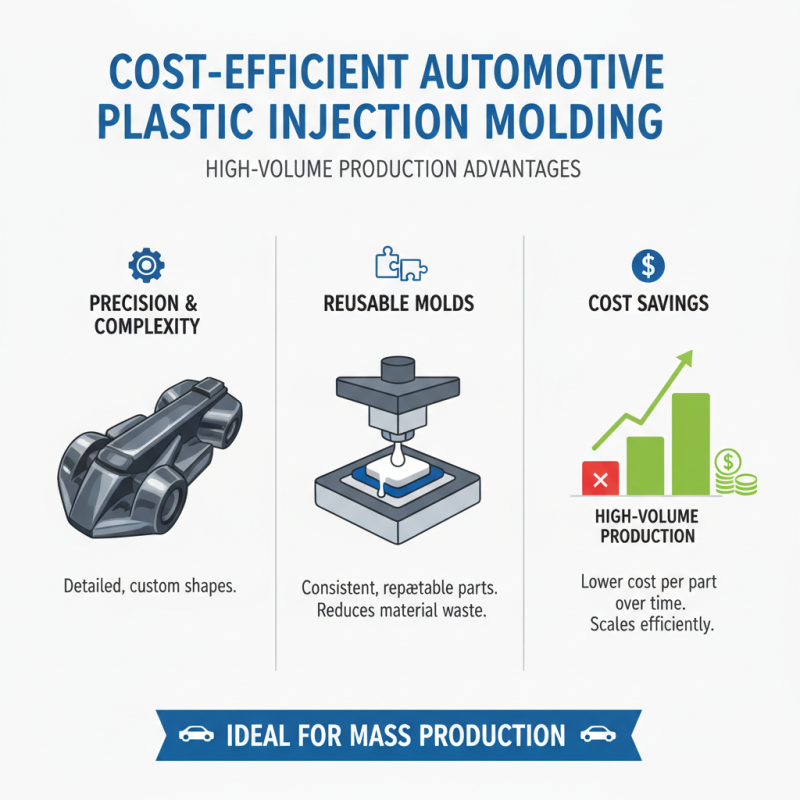

Custom automotive plastic injection molding offers significant advantages in manufacturing processes. It allows for high precision and intricate designs. This is crucial for components like dashboards, panels, and other interior parts. Manufacturers can achieve complex shapes that metals can't deliver easily. Additionally, it reduces production times considerably. Quick turnaround is essential in the competitive automotive sector.

Another key benefit is cost efficiency. The initial setup costs can be high, but the long-term savings are substantial. The ability to produce large volumes reduces the price per unit. This is vital for car manufacturers looking to maintain profit margins. However, there are challenges. Not every design is suitable for injection molding; some may need redesigns.

Moreover, the environmental impact should not be overlooked. The use of plastics raises concerns about sustainability. Manufacturers must consider recycling options. Continuous improvement in materials can help address these issues. In the end, while custom automotive plastic injection molding has its drawbacks, its benefits in efficiency and design cannot be ignored.

Custom automotive plastic injection molding offers many advantages, especially regarding cost efficiency in high-volume production. This manufacturing process enables the creation of precise and complex parts at a lower cost over time. By using molds repeatedly, manufacturers can significantly decrease production costs. The initial setup may be expensive, but the savings become apparent as production scales up.

When considering this method, pay attention to the material selection. Choosing the right plastic can enhance durability and performance, leading to longer-lasting components. Keep in mind that not all plastics suit every application. Testing different materials can reveal hidden benefits or potential drawbacks.

It’s also vital to collaborate with skilled engineers. Their expertise ensures the design minimizes waste and maximizes efficiency. They can help troubleshoot issues that often arise during production. Be prepared to revisit designs if required. Continuous improvement is crucial in this industry. Adjusting designs based on feedback can lead to significant savings in the long run. By focusing on these aspects, automotive manufacturers can truly harness the benefits of custom plastic injection molding.

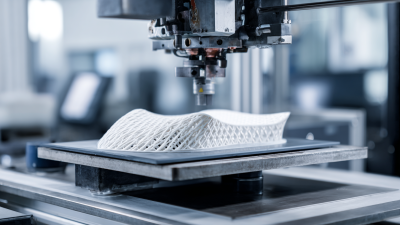

Custom automotive plastic injection molding offers significant design flexibility that enhances various automotive applications. Advanced techniques allow for intricate shapes and minor details. This flexibility plays a crucial role in both aesthetics and functionality. For instance, manufacturers can easily create lighter components, which improve vehicle efficiency.

Consider the design phase carefully. Accurate 3D modeling is essential. Utilize software that provides realistic simulations. This can help visualize the end product and catch potential issues early. Prototyping is another key step. It allows for tangible assessments before mass production. Don’t underestimate the value of iterative feedback. Refining designs based on feedback can lead to superior outcomes.

Be mindful of material selection too. Each material behaves differently during molding. Experimenting with varying compositions can yield unexpected results. Not every design translates perfectly to production. Some designs may need adjustments to fit manufacturing capabilities. Identifying these issues early saves time and costs later.

Custom automotive plastic injection molding offers superior material properties that enhance the durability of vehicle components. According to industry reports, plastics can provide up to 20% weight reduction compared to traditional materials. This weight savings translates into improved fuel efficiency and performance. Components made from high-quality injected plastics resist corrosion and fatigue better than metals. This results in longer-lasting parts that can withstand harsh automotive environments.

Moreover, the customization aspect allows manufacturers to choose specific minerals and additives. These choices can significantly improve tensile strength and impact resistance. Data shows that automotive plastics can achieve tensile strength of up to 80 MPa, making them suitable for critical applications. Alternatively, some designs may require flexibility and elasticity, which can also be engineered through injection molding.

The versatility of materials leads to innovative designs and solutions, but improper selection can affect the end product. Some manufacturers overlook the importance of thorough testing in real-world conditions. Inconsistencies in molding processes can lead to defects, which may compromise the product design. Attention to quality assurance is crucial for achieving desired performance standards. Although plastics offer many benefits, ongoing evaluation and refinement of materials are necessary to maximize durability and effectiveness in automotive applications.

The sustainability of plastic injection molding is a pressing concern. Many manufacturers are exploring eco-friendly materials to lessen their environmental footprint. Biodegradable plastics have emerged as a promising alternative. These materials can break down more easily in landfills, reducing pollution. However, not all recyclable materials perform equally. The efficacy of these solutions requires continuous evaluation.

Plastic injection molding processes can be optimized to reduce waste. For example, closed-loop systems recapture excess plastic, minimizing resource consumption. Yet, this technology isn’t widely adopted. Companies face challenges in implementation. They often prioritize speed over sustainability, which can hinder progress.

Furthermore, consumer awareness is a crucial driver. Buyers are increasingly demanding sustainable practices. This pressure can encourage manufacturers to innovate. However, some businesses struggle to balance cost and eco-friendliness. Adopting greener methods can raise upfront expenses, which may deter smaller operations. A shift in mindset is essential for long-term benefits.

| Benefit | Description | Environmental Impact |

|---|---|---|

| Reduced Waste | Custom molding processes allow for precise shaping, minimizing excess materials. | Lower resource consumption and reduced plastic waste in landfills. |

| Energy Efficiency | Modern processes lower energy usage during production. | Decreased carbon footprint associated with energy production. |

| Material Versatility | Ability to use recycled plastics and eco-friendly materials. | Promotes recycling efforts and supports sustainable material sourcing. |

| Improved Durability | Custom molds produce stronger components that last longer. | Reduces frequency of product replacement, thus conserving resources. |

| Reduced Transportation Emissions | Localized manufacturing reduces the distance products must travel. | Decreases greenhouse gas emissions from transportation. |