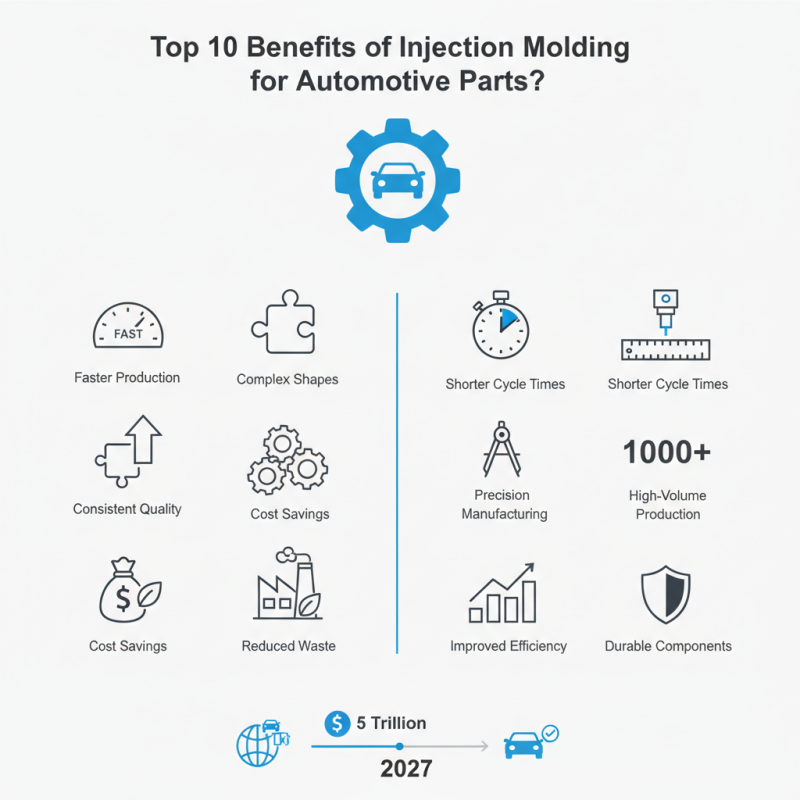

Injection molding technology plays a crucial role in the production of automotive parts. With the global automotive market projected to reach $5 trillion by 2027, efficient manufacturing processes are essential. Injection molding offers significant advantages in producing high-quality components. According to industry reports, it allows for faster production speeds, reducing cycle times effectively.

This method enables manufacturers to create complex shapes with precision. In fact, injection molding can produce thousands of parts with consistent quality. However, the initial costs can be high, and companies must weigh the financial investment against long-term benefits. Additionally, there may be challenges related to material selection and design optimization.

Even with these considerations, the demand for injection molding in automotive parts remains strong. The ability to reduce waste and improve production efficiency cannot be overlooked. Industry data reveals that companies embracing this technology often see significant savings in operational costs. Thus, exploring the landscape of injection molding automotive parts becomes increasingly crucial for businesses aiming to stay competitive.

Injection molding is a go-to method for producing automotive parts. This technique allows manufacturers to create complex shapes with high precision. As a result, parts fit together seamlessly. With efficient use of materials, waste is minimized during production. This efficiency can lower costs, making it economically viable for large-scale production.

The speed of injection molding is remarkable. Parts can be produced quickly, meeting the fast-paced demands of the automotive industry. However, the initial setup can be time-consuming. It requires careful planning and design to avoid costly mistakes. Additionally, the tooling involved is expensive, which can be a hurdle for new projects. Nevertheless, the long-term benefits often outweigh these initial challenges.

Another advantage is the versatility of materials used. Various plastics can be molded, allowing for options that meet different automotive needs. Some materials enhance safety features, while others improve durability. However, not all materials perform well under extreme conditions. Manufacturers must be cautious in their choices, constantly reflecting on their material selection process. Overall, injection molding remains a vital part of automotive production due to its many benefits.

The cost efficiency of injection molding for mass production is undeniable. This process allows manufacturers to create complex automotive parts at a lower cost. A recent report from the Society of Automotive Engineers highlights that injection molding reduces production costs by up to 40%. This significant savings stems from the reduction in labor and material costs.

Injection molding has a quick cycle time, which leads to faster production. Molding can produce thousands of parts in a single day. This high efficiency meets the growing demand in the automotive sector. However, the initial setup cost can be daunting for small manufacturers. They may struggle with the high upfront investment for molds. Yet, these costs often pay off over time as production ramps up.

Tips: Consider starting small with low-volume projects to test injection molding. This approach minimizes risk. Networking with industry experts can provide valuable insights into potential pitfalls. Always evaluate your production needs carefully before investing in molds. Adjusting the design can further optimize costs and efficiency.

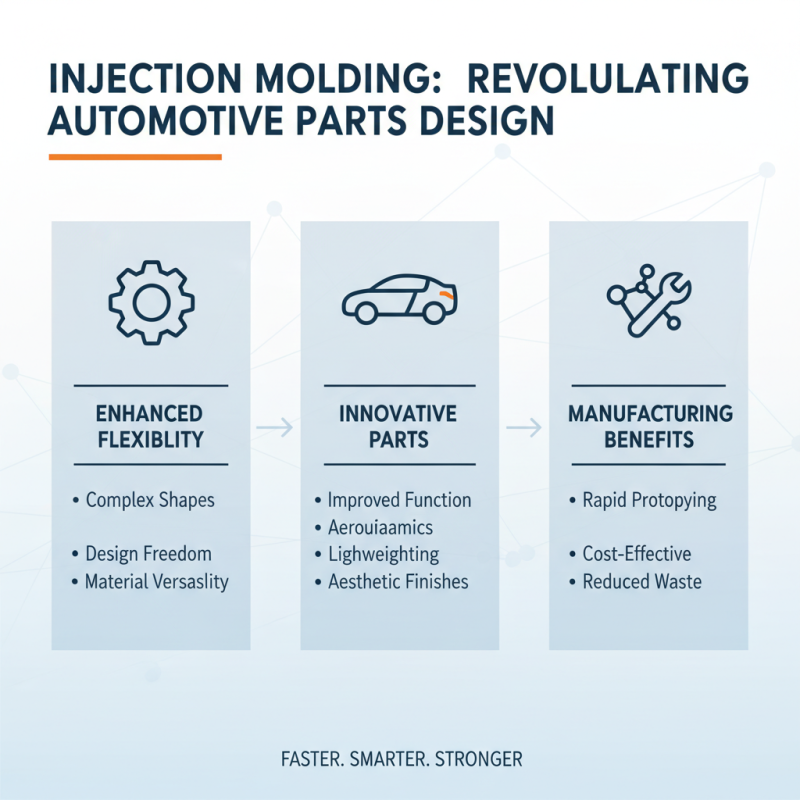

Injection molding is transforming automotive parts design. This technique allows for enhanced flexibility, making it easier to create complex shapes. Manufacturers can experiment with different designs, materials, and finishes. The result? Innovative parts that improve both function and aesthetics.

Consider the use of multi-material injection molding. This method enables the combination of rigid and flexible components seamlessly. However, it requires careful planning. Balancing the properties of various materials is not straightforward. Sometimes, the outcome may not align with expectations.

Tips: Always prototype your designs before full production. This step can save money and time. Testing different prototypes can highlight unforeseen issues early in the process. Collaboration among team members also fosters fresh ideas. Open communication may lead to unexpected solutions.

Designing for injection molding does come with challenges. Wall thickness needs to be consistent to avoid defects. Additionally, draft angles are essential for easy part release. Ignoring these factors can result in increased costs and delays. Regular design reviews can help catch mistakes before they escalate.

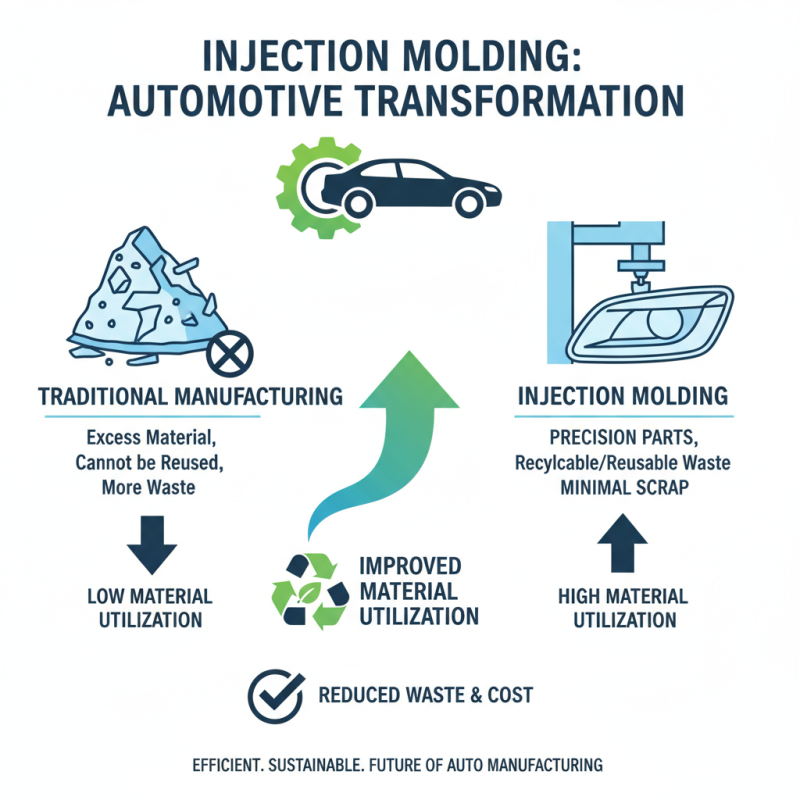

Injection molding is transforming the automotive industry. One of its most significant advantages is improved material utilization. This process efficiently uses raw materials, minimizing waste. Traditional manufacturing often results in excess material that cannot be reused. In contrast, injection molding produces parts with a high degree of precision. The leftover material can be recycled or repurposed, which helps reduce overall waste.

Moreover, the process contributes to environmental sustainability. By utilizing only what is needed, companies can lower their carbon footprint. This efficiency becomes crucial as automotive manufacturers face increasing pressure to adopt eco-friendly practices. However, some may struggle to optimize this process fully. They might overlook ways to recycle or fail to understand how to reduce waste even further. Finding those opportunities requires introspection and a commitment to continuous improvement.

Injection molding offers many benefits, but it’s not foolproof. Companies need to invest in training and equipment to perfect the process. Without proper implementation, waste reduction goals may fall short. The journey of improving material utilization is ongoing. Every small step counts toward a more sustainable future in automotive manufacturing.

Injection molding offers remarkable advantages for automotive parts, particularly in terms of quality and precision. A report from the Automotive Plastics Market notes that injection molding can achieve tolerances as tight as ±0.005 inches. This level of precision ensures that components fit seamlessly, reducing the risk of defects during assembly. Manufacturers rely on this accuracy to produce intricate designs that align with modern vehicle aesthetics and functionality.

Moreover, the consistency provided by injection molding is noteworthy. Once a mold is created, the same part is produced repeatedly with minimal variation. A study by Grand View Research indicates that the global automotive plastic market size is expected to reach USD 45.5 billion by 2027. This growth highlights the industry’s reliance on high-quality plastic components. However, there is a cautionary note: defects can occur during the molding process, potentially leading to waste. Continuous improvements in technology and techniques are necessary to address these challenges effectively.

Attention to detail can also elevate the performance of automotive parts. While injection molding excels in quality, it requires careful monitoring throughout production. For instance, material selection plays a crucial role in the final performance of components. High-quality polymers can enhance durability and flexibility, but the wrong choice can diminish these benefits. Balancing cost and quality remains a crucial aspect of the manufacturing process, demanding ongoing evaluation and adjustment.

| Benefit | Description | Impact on Automotive Industry |

|---|---|---|

| High Precision | Injection molding achieves tight tolerances for complex shapes. | Enhances part fit and function, leading to improved vehicle performance. |

| Cost Efficiency | Mass production reduces the cost per unit significantly. | Lower manufacturing costs allow for competitive pricing. |

| Material Variety | Compatible with numerous materials including plastics and composites. | Increases design flexibility and material selection for automotive components. |

| Fast Production Speed | Cycle times can be very short, leading to quicker output. | Supports just-in-time manufacturing processes in the automotive sector. |

| Low Waste | Material waste during production is minimal compared to traditional techniques. | Contributes to sustainable manufacturing practices in the industry. |

| Consistency | Produces identical parts that meet specifications each time. | Reduces rework and improves overall product quality. |

| Design Flexibility | Complex designs can be easily achieved with injection molding. | Encourages innovation and advanced designs in automotive parts. |

| Enhanced Strength | Injection molding can produce stronger components compared to alternatives. | Improves durability and safety of automotive parts. |

| Better Surface Finish | Results in high-quality surface finishes with less need for post-processing. | Reduces production time and costs associated with finishing processes. |

| Scalability | Easily scalable for large-scale production without significant changes. | Facilitates growth in production to meet increasing demand. |