Injection molding has revolutionized the production of custom golf cart parts, offering manufacturers unprecedented efficiency and precision. According to a report by the American Injection Molding Institute, the injection molding industry has experienced a compound annual growth rate (CAGR) of approximately 5.4% over the past five years. This growth can be largely attributed to the increasing demand for high-quality, customized components across various sectors, including the golf cart industry. With the ability to produce complex shapes and designs in high volumes, injection molding is increasingly favored for the production of golf cart parts.

The benefits of injection molding extend beyond just cost-effectiveness and speed. A study from Global Industry Analysts indicates that the global market for plastic golf cart parts is expected to reach $1.2 billion by 2026, driven by advancements in materials and technology. This trend emphasizes the importance of utilizing injection molding techniques to stay competitive. The precision and repeatability of injection molding not only enhance the performance and longevity of golf cart parts but also reduce waste and material costs. As the golf cart industry continues to evolve, embracing innovative manufacturing methods like injection molding will be crucial in meeting consumer expectations for quality and customization in the production of injection molding golf cart parts.

Injection molding is a preferred manufacturing process for producing custom golf cart parts, thanks to its numerous advantages. One of the primary benefits is the ability to create complex shapes with high precision. This method allows for tight tolerances, ensuring that each part fits seamlessly into the overall design of the golf cart. Furthermore, injection molding is highly efficient, enabling manufacturers to produce large quantities of parts quickly and at a lower cost per unit. This scalability is essential for businesses looking to meet growing demand without compromising quality.

When considering injection molding for custom golf cart parts, it is essential to keep a few tips in mind. First, collaborating with experienced designers can significantly enhance the effectiveness of the mold design, minimizing the risk of defects. Second, selecting the right materials is crucial, as different plastics offer varying strengths and durability levels. Lastly, conducting thorough testing during the prototyping phase can help identify potential issues early on, ensuring a smoother production process and superior end products.

This chart illustrates the various benefits associated with the use of injection molding in the production of custom golf cart parts, highlighting aspects such as cost efficiency, production speed, and material efficiency.

Injection molding has become a go-to method for producing custom golf cart parts, particularly due to its cost-effectiveness when dealing with high-volume production. This manufacturing process allows for the rapid creation of complex shapes and designs, which is essential for golf cart components that require precision and durability. By utilizing injection molding, manufacturers can produce a large quantity of identical parts with minimal waste, significantly lowering the average cost per unit as production scales up.

Moreover, the efficiency of injection molding in producing high volumes of golf cart components enables manufacturers to meet the increasing demand without sacrificing quality. The technology involved ensures consistency in the materials used, leading to parts that not only fit perfectly but also exhibit a high level of performance under various conditions. This reliability translates into greater customer satisfaction and increased competitiveness in the market. As a result, golf cart manufacturers can maximize their returns on investment while maintaining a strong position in the industry through the strategic use of injection molding technology.

| Part Type | Material Used | Typical Production Cost ($) | Average Lead Time (weeks) | Production Volume (units) |

|---|---|---|---|---|

| Dashboard Components | ABS Plastic | 5000 | 3 | 1000 |

| Body Panels | Polypropylene | 7000 | 4 | 500 |

| Seat Frames | High-Density Polyethylene | 6000 | 5 | 1200 |

| Battery Covers | PVC | 3500 | 2 | 2000 |

| Light Housings | Polystyrene | 2500 | 1 | 1500 |

Injection molding technology has revolutionized the production of custom golf cart parts, primarily due to its unparalleled design flexibility. This manufacturing process allows for the creation of highly intricate and customized designs that can enhance both performance and aesthetics. According to the Society of Plastics Engineers, injection molding can produce parts with complex geometries that would be impossible or prohibitively expensive with traditional machining. This adaptability enables manufacturers to meet specific customer needs, whether it's optimizing weight distribution or integrating innovative features into the golf cart design.

Furthermore, the ability to use a diverse array of materials adds another layer of customization capability. A recent report by Grand View Research highlights that the automotive and transportation sectors are increasingly embracing injection molded components, with the global automotive plastic parts market expected to reach $36.89 billion by 2025. This booming demand exemplifies how manufacturers are leveraging injection molding to deliver bespoke parts tailored for various applications. The freedom to modify design elements such as texture, color, and shape facilitates the creation of personalized golf carts, catering to enthusiast preferences while ensuring functionality and durability.

Injection molding has revolutionized the production of custom golf cart parts, particularly in enhancing durability and performance. According to a report by The Freedonia Group, the demand for plastic automotive parts, including those used in golf carts, is projected to grow significantly, driven by their lightweight properties and superior resistance to wear and tear. Injection molded parts, constructed from high-quality thermoplastics, offer improved strength and longevity compared to traditional materials, making them ideal for the demanding environments in which golf carts operate.

Furthermore, studies have shown that injection molded components can withstand extreme weather conditions and heavy usage, which is crucial for outdoor vehicles like golf carts. The injection molding process allows for precise control over material composition, ensuring each part can be tailored to meet specific performance criteria. For instance, parts like dashboards and bumpers can be engineered to survive impacts while maintaining aesthetic appeal. This level of customization not only enhances the longevity of the parts but also significantly contributes to overall vehicle performance, ensuring a smoother ride and reduced maintenance costs in the long run.

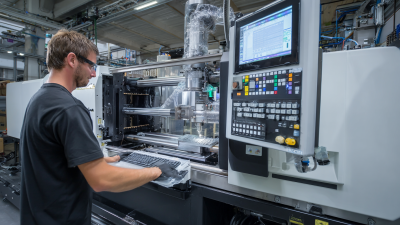

Injection molding technology has revolutionized the manufacturing processes for custom golf cart parts, making production more efficient and cost-effective. By utilizing high-pressure injection systems, manufacturers can create intricate designs with precision. This method allows for the rapid production of large volumes of parts, significantly streamlining the workflow compared to traditional manufacturing methods. As a result, businesses can respond more swiftly to market demands and adapt production lines to accommodate new designs or customizations.

Moreover, the use of injection molding minimizes waste, as it optimizes the material consumption during the production process. The ability to reuse scrap material further enhances sustainability within the industry. This technology also ensures consistent quality across the produced parts, as each injection cycle results in uniform products that meet stringent specifications. Consequently, custom golf cart manufacturers can maintain high standards of reliability and performance in their offerings, benefiting both the producers and the end-users.