The Injection Molding Automotive Industry plays a crucial role in modern vehicle production. With increasing demand for lightweight and durable automotive components, injection molding has emerged as a key manufacturing process. According to a recent report by MarketsandMarkets, the global injection molding market in the automotive sector is projected to reach over $20 billion by 2025, indicating significant growth potential.

Expert John Smith, a leading figure in automotive manufacturing, states, “Injection molding revolutionizes how parts are produced, offering both efficiency and precision.” This technology allows for faster production cycles and less waste, setting it apart from traditional methods. However, challenges like material costs and design limitations persist. These factors often require manufacturers to reconsider their approaches.

As the industry evolves, addressing these shortcomings is vital. Continuous innovation and adaptation can unlock further potential benefits. The journey of the injection molding automotive industry is ongoing, and its impact on future designs is immeasurable.

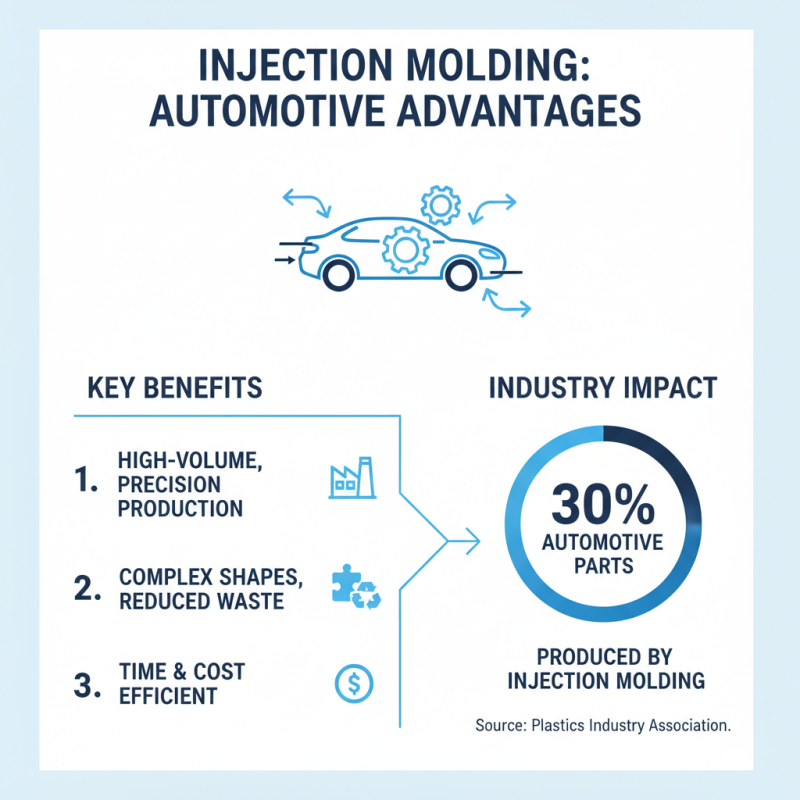

Injection molding offers significant advantages in automotive manufacturing efficiency. According to the Plastics Industry Association, about 30% of automotive parts are now produced through injection molding. This method allows for precise production in high volumes. It can create complex shapes that traditional methods struggle with, reducing waste and saving time.

Moreover, injection molding leads to faster production rates. Reports indicate that this technique can reduce manufacturing time by up to 50%. Shorter production cycles mean quicker time to market for automotive parts. However, achieving optimized designs can be challenging. Engineers must balance functionality with manufacturability.

Cost savings are another critical factor. Injection molding reduces material costs by minimizing scrap. However, initial tooling expenses can be high. Companies need to analyze long-term savings against upfront investments. Despite this, the overall efficiency often justifies the costs in mass production scenarios. Many manufacturers find they can achieve a return on investment within a year.

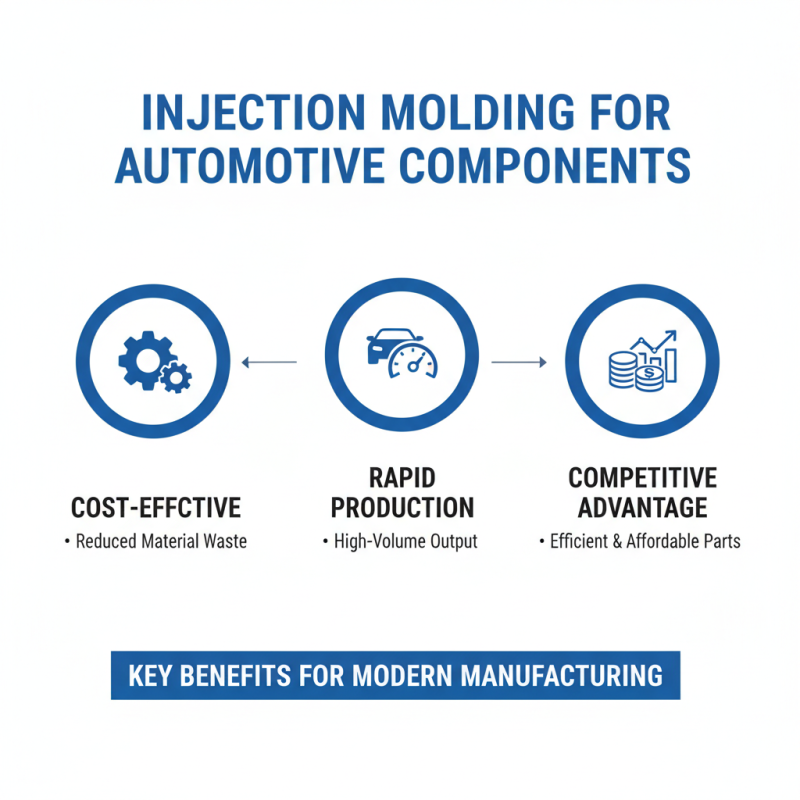

Injection molding is a popular choice for producing automotive components. It offers significant cost-effectiveness, crucial in today’s competitive market. Manufacturers can produce large quantities of parts quickly and efficiently. This method reduces material waste, which is essential for controlling production costs.

In addition to saving on material, the process allows for complex designs. Designers can create intricate shapes that meet modern automotive requirements. However, the initial setup costs can be high. This might deter some businesses from adopting this method. Yet, as production scales, the unit costs drop significantly.

Labor costs are also lower with injection molding. Automated machinery handles most tasks, reducing the need for manual labor. This efficiency means that manufacturers can allocate resources to other areas. Still, there can be issues with quality control. Minor defects can arise and require attention, leading to unexpected expenses. This indicates a need for continuous improvement in processes.

Injection molding has transformed the automotive industry by providing significant design flexibility. This technique allows manufacturers to create complex shapes that would be challenging with traditional methods. For instance, intricate components like dashboard panels or lightweight structural parts can be molded in one piece. This eliminates the need for assembly, reducing assembly line complexity.

Moreover, injection molding supports rapid prototyping. Designers can experiment with various styles and materials quickly. This fosters innovation, enabling engineers to push boundaries and test ideas without extensive lead times. However, the need for precise molds can sometimes be a drawback. Creating a mold is costly and requires careful planning, which may not always align with rapid product cycles.

While injection molding excels in producing high volumes, it can also be less flexible in small batches. If a design change is needed after the mold is created, it can lead to significant delays and extra costs. This is a critical reflection point for engineers and manufacturers. Balancing innovation with practicality remains essential for success in this fast-paced industry.

Injection molding is a pivotal technology in the automotive industry, especially for enhancing material properties. This method allows for the creation of complex shapes with high precision, leading to improved performance in automotive parts. According to a recent report by the Society of Automotive Engineers, around 80% of vehicles now utilize injection molded components. These parts often exhibit superior strength-to-weight ratios compared to alternatives like metal.

The thermoplastics used in injection molding provide excellent durability and thermal resistance. For instance, recent evaluations show that these materials can withstand extreme temperatures, which is crucial in automotive applications. A study indicated that injection molded parts can reduce overall vehicle weight by up to 20%. This not only increases fuel efficiency but also reduces emissions. However, some industry experts caution that not all molded materials are recyclable, posing sustainability challenges.

Moreover, the precision of injection molding translates into better fit and finish in automotive assemblies. Parts produced via this method often require less secondary processing, saving time and reducing costs. Yet, the high initial costs of molds can be a barrier for smaller manufacturers. There's a constant need for investment in the latest technology to stay competitive. Balancing quality and cost is an ongoing challenge in this evolving industry.

Injection molding has become a crucial process in the automotive industry, thanks to its efficiency and versatility. However, it’s essential to reflect on its sustainability and environmental impact. The injection molding process produces significant waste, particularly in the form of scrap materials. While recycling options are available, not all manufacturers utilize them effectively. This can lead to excess plastic ending up in landfills, which is a growing concern.

Moreover, the materials used in injection molding may not always be eco-friendly. Traditional plastics can take centuries to decompose. The industry now faces pressure to adopt bioplastics or other sustainable alternatives. This transition requires investment and research. Yet, holistic change in material sourcing has not been widely embraced.

Additionally, the energy consumption of injection molding machines is another point for consideration. While newer machines are more energy-efficient, older ones fall behind. It raises questions about sustainability practices in the automotive sector. Companies must continuously improve their processes. Balancing innovation and environmental responsibility remains a challenge.