In the rapidly evolving landscape of manufacturing, the adoption of

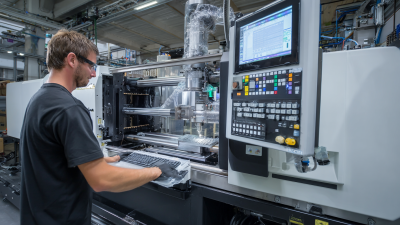

Rapid Injection Molding has emerged as a game-changer for companies looking to enhance their production efficiency.

According to a recent report by the Rapid Manufacturing Association (RMA), businesses that implemented

Rapid Injection Molding techniques reported, on average, a 25% increase in production efficiency. This impressive statistic underscores the necessity for manufacturers to embrace innovative processes that streamline operations and reduce lead times.

"Rapid Injection Molding not only accelerates the production cycle but also supports design iterations, allowing companies to stay competitive in a fast-paced market."Her insights reflect the growing consensus within the industry that agility and speed are paramount. As manufacturers prioritize responsiveness and quality, Rapid Injection Molding stands out as an essential component in achieving these goals, offering a blend of efficiency, cost-effectiveness, and adaptability.

Rapid injection molding has emerged as a transformative approach within the manufacturing industry, offering substantial improvements in production efficiency. This innovative method allows for quicker turnaround times and reduced costs, making it a game changer for companies aiming to streamline their operations. With its ability to produce high-quality parts in a fraction of the time compared to traditional molding processes, rapid injection molding is reshaping the landscape of product development.

Rapid injection molding has emerged as a transformative approach within the manufacturing industry, offering substantial improvements in production efficiency. This innovative method allows for quicker turnaround times and reduced costs, making it a game changer for companies aiming to streamline their operations. With its ability to produce high-quality parts in a fraction of the time compared to traditional molding processes, rapid injection molding is reshaping the landscape of product development.

Tips:

To fully leverage the benefits of rapid injection molding, focus on optimizing your design for manufacturability. Simplifying part geometries and minimizing the number of components can significantly enhance production speed. Additionally, selecting the right materials upfront can prevent delays and ensure that the final products meet quality standards.

Another key advantage of rapid injection molding is its scalability. Businesses can easily adjust production volumes based on market demand without sacrificing quality. This flexibility not only supports cost-effective production runs but also allows for quick adaptations to changes in design or consumer preferences.

Tips:

Regularly review market trends and consumer feedback to inform your production strategies. Implementing agile manufacturing practices can help you stay ahead in a competitive environment, ensuring that you can meet client needs promptly and efficiently.

Rapid injection molding is revolutionizing manufacturing processes by significantly enhancing speed and efficiency. Traditional injection molding can be time-consuming, involving lengthy setup times and extensive production cycles. However, with rapid injection molding, manufacturers can significantly reduce these timeframes, allowing for quicker turnaround times on product development and production. This method utilizes advanced technologies and streamlined workflows to minimize delays, enabling businesses to respond to market demands promptly.

Furthermore, the enhanced speed of rapid injection molding doesn't just accelerate production; it also allows for greater flexibility in design iterations. Manufacturers can quickly produce prototypes and test them in real-world applications, facilitating faster feedback and improvements. This iterative process not only accelerates time-to-market but also fosters innovation, as businesses can explore more ideas without the risk of significant time or financial investments.

Thus, rapid injection molding stands out as a game-changer in modern manufacturing, driving efficiency and responsiveness in an increasingly competitive landscape.

Rapid injection molding represents a game-changing approach in the manufacturing sector, particularly when it comes to cost-effectiveness. By utilizing advanced techniques and technology, manufacturers can significantly reduce operational expenses associated with traditional molding methods. The streamlined process minimizes material waste and optimizes production time, which translates to lower labor costs and faster turnaround rates. This enhanced efficiency allows companies to allocate their resources more effectively, resulting in substantial savings.

Moreover, rapid injection molding allows for lower upfront investment in tooling, as these molds can be produced quickly and less expensively. This is especially beneficial for startups or companies looking to test new designs without committing to large-scale production costs. In addition, the flexibility of rapid injection molding enables manufacturers to adapt swiftly to market demands, facilitating smaller production runs at lower costs. Consequently, businesses can launch products more quickly and respond to consumer preferences with agility, fortifying their competitive edge in the market.

Rapid injection molding is reshaping the landscape of manufacturing by offering improved design flexibility and enhanced customization options. This technique allows for the swift production of prototypes and end-use parts, accommodating varying design complexities without substantial increases in costs or time. According to a recent industry report, the market demand for rapid injection molding is expected to see an increase in production efficiency by up to 25%, as companies leverage its capabilities to accelerate product development cycles.

The ability to easily modify molds and adapt designs is crucial in today’s fast-paced market, particularly in sectors such as medical manufacturing and 3D printing. With the rise of personalized medicine and tailored medical devices, the integration of rapid injection molding into additive manufacturing is enabling manufacturers to create intricate and specialized designs quickly. Notably, the North American metal powder market, as outlined in a recent analysis, is also experiencing a surge in demand, signaling a shift towards more specialized materials that enhance the performance of 3D-printed components. This synergy between rapid injection molding and additive manufacturing is vital for businesses looking to stay competitive while meeting the diverse needs of their customers.

Rapid injection molding is not only a game-changer for production efficiency but also a crucial factor in maintaining high product standards. The process allows for quick turnaround times while ensuring that every unit produced adheres to stringent quality controls. By utilizing advanced technology and precision tooling, manufacturers can produce complex designs with remarkable accuracy, reducing the likelihood of defects and minimizing waste. This immediate feedback loop allows for real-time adjustments, further enhancing product quality.

Moreover, the flexibility of rapid injection molding provides an opportunity for rigorous quality assurance protocols. With the ability to create prototypes swiftly, companies can conduct thorough testing before mass production. This proactive approach to quality assurance not only fosters customer trust but also ensures that the final products meet both regulatory requirements and customer expectations. Thus, rapid injection molding stands out as a vital method for businesses aiming to balance high production volumes with exceptional quality.