In recent years, the field of Custom Plastic Injection Molding has witnessed significant advancements. Companies are now exploring innovative techniques to improve efficiency and reduce costs. In 2026, we can expect these trends to continue evolving.

New materials and technologies are reshaping the landscape of custom molding. For instance, incorporating sustainable materials can enhance production processes. However, challenges remain. Many manufacturers still struggle with the transition to greener solutions. There is constant pressure to balance cost-effectiveness with environmental responsibility.

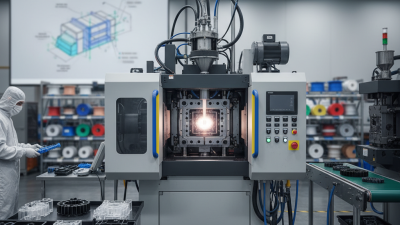

Furthermore, the demand for customization continues to rise. Brands seek unique designs to stand out in a competitive market. Yet, achieving precision in Custom Plastic Injection Molding is not always easy. Providers must adapt their approaches and invest in new machinery. Reflecting on these issues is crucial. As the industry pushes forward, staying informed about innovations is more important than ever.

The custom plastic injection molding industry is rapidly evolving. Recent studies highlight that the global market is expected to reach $382 billion by 2026. Companies are now focusing on innovative techniques to enhance efficiency and sustainability. For instance, advanced cooling systems can reduce cycle times significantly, boosting productivity.

Tips: Evaluate your current processes. Are there areas where you can upgrade machinery or improve design efficiency? Small changes can lead to big results.

Another emerging trend is the integration of smart technology. IoT-enabled equipment can monitor production in real-time. This allows for immediate adjustments, reducing waste. However, implementing such technology requires careful planning. Many companies are still grappling with the complexities of data management.

Tips: Invest in training. Ensure your team understands the new tools. This investment can pave the way for smarter production methods. Embrace the change, but do so thoughtfully.

The world of plastic injection molding is rapidly evolving, with innovative materials leading the charge. Recent industry reports indicate that over 45% of companies are exploring advanced materials to enhance product performance. One notable material is bio-based plastics, which have gained traction due to their sustainability. These materials often reduce carbon footprints compared to traditional plastics. However, their availability and production costs can be limiting factors.

Another exciting trend is the use of high-performance thermoplastics. They offer exceptional strength and durability, making them suitable for demanding applications in various industries. Data shows that the adoption of these materials has increased by 30% in the last year alone. Yet, the technical challenges in processing them often necessitate new equipment and training for workers, which can slow down integration.

Recycled plastics are also making waves in the industry. Companies are becoming more aware of waste management issues, leading to a rising interest in using recycled materials. Despite this, there are ongoing concerns about maintaining quality. The inconsistency of recycled inputs can sometimes lead to defective products. As the sector moves forward, balancing innovation with these challenges will be crucial for manufacturers aiming to stay competitive.

| Technique | Innovation | Material Used | Application Area | Sustainability |

|---|---|---|---|---|

| Multi-material Injection Molding | Enhanced product functionality | Polypropylene and TPE | Consumer Electronics | Recyclable components |

| Gas-assisted Injection Molding | Weight reduction and cost efficiency | Acrylic and Nylon | Automotive Parts | Reduced material use |

| 3D Printing Integration | Rapid prototyping and customization | PLA and ABS | Medical Devices | Biodegradable options |

| Hydraulic Injection Molding | Improved precision and speed | Polycarbonate | Aerospace Components | Reusable molds |

| Foaming Injection Molding | Lightweight structures | Polyurethane | Construction Materials | Energy efficient production |

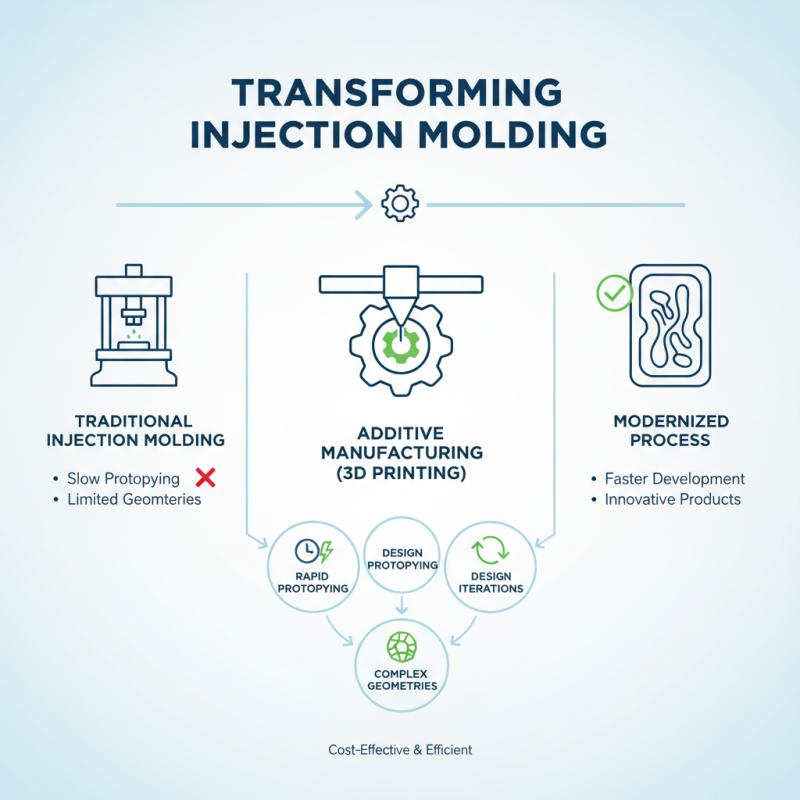

Additive manufacturing is transforming injection molding processes. This technology allows for rapid prototyping and design iterations. By integrating 3D printing techniques, manufacturers can produce complex geometries that were previously difficult or costly to achieve.

One key advantage is the reduction in lead time. Traditional molds require extensive setup. In contrast, additive methods enable quicker adjustments. However, this speed can lead to oversights in the initial design phases. Sometimes, designs rush to completion may not fully consider functional requirements.

Cost savings are another significant benefit. Reduced material waste is achievable through precise additive methods. Yet, the initial investment in advanced equipment can deter some companies. Balancing the cost against benefits is a critical reflection for many in the industry. Innovations are exciting, but they must be approached cautiously to avoid pitfalls in production efficiency.

Automation and robotics are transforming the plastic injection molding industry. Recent studies indicate that over 45% of companies are integrating automated technologies into their production lines. This shift increases efficiency and reduces labor costs. Automated systems can produce complex parts with precision, cutting down lead times significantly. For instance, the implementation of robotic arms has been reported to enhance cycle times by up to 30%.

However, this transition is not without challenges. Many manufacturers face difficulties in training employees to work alongside advanced machinery. Retooling systems for automation demands significant investment. A report suggests that while automation can reduce costs, it may also lead to job displacement, raising workforce concerns. Companies must balance the benefits of innovation with the need for skilled labor.

The future of plastic injection molding lies in embracing automation. Industry reports indicate that 57% of businesses plan to invest in robotics technology within the next few years. This can lead to more consistent product quality and less waste. However, as automation advances, the industry must reflect on its impact on employment and ensure that existing workers are not left behind.

In recent years, sustainable practices have gained momentum in the plastic injection molding industry. Many manufacturers are exploring biodegradable materials. These eco-friendly options reduce environmental damage. For instance, plant-based plastics offer a viable alternative to traditional materials. They can decompose more easily, but they still face durability challenges.

Innovative molding techniques are evolving to support sustainability. One approach involves using recycled plastics in the molding process. This reduces waste and lessens the demand for new plastic production. However, the quality of recycled materials can vary, leading to inconsistencies in finished products. Each step requires careful evaluation to ensure performance standards.

Energy-efficient machinery is another key aspect of sustainable practices. New designs minimize energy consumption during production. They aim to lower carbon footprints significantly. Yet, switching to these technologies can be costly. Manufacturers must weigh the long-term benefits against the upfront investment. Embracing sustainability often comes with trade-offs that require thoughtful decision-making.