In the competitive landscape of the motorcycle industry, the demand for high-quality and reliable components has never been more critical. According to a recent report by Grand View Research, the global motorcycle parts market is expected to reach $XX billion by 2025, with a significant share driven by advancements in manufacturing technologies such as injection molding. This method allows for the efficient production of injection molding motorcycle parts that not only enhance performance but also ensure durability and reliability under strenuous conditions. As manufacturers strive to meet the rigorous demands for both speed and safety, sourcing the best injection molding motorcycle parts becomes essential.

This blog will explore effective strategies for identifying and procuring these components, ultimately helping motorcycle enthusiasts and professionals to enhance their vehicles' performance and reliability through superior manufacturing practices.

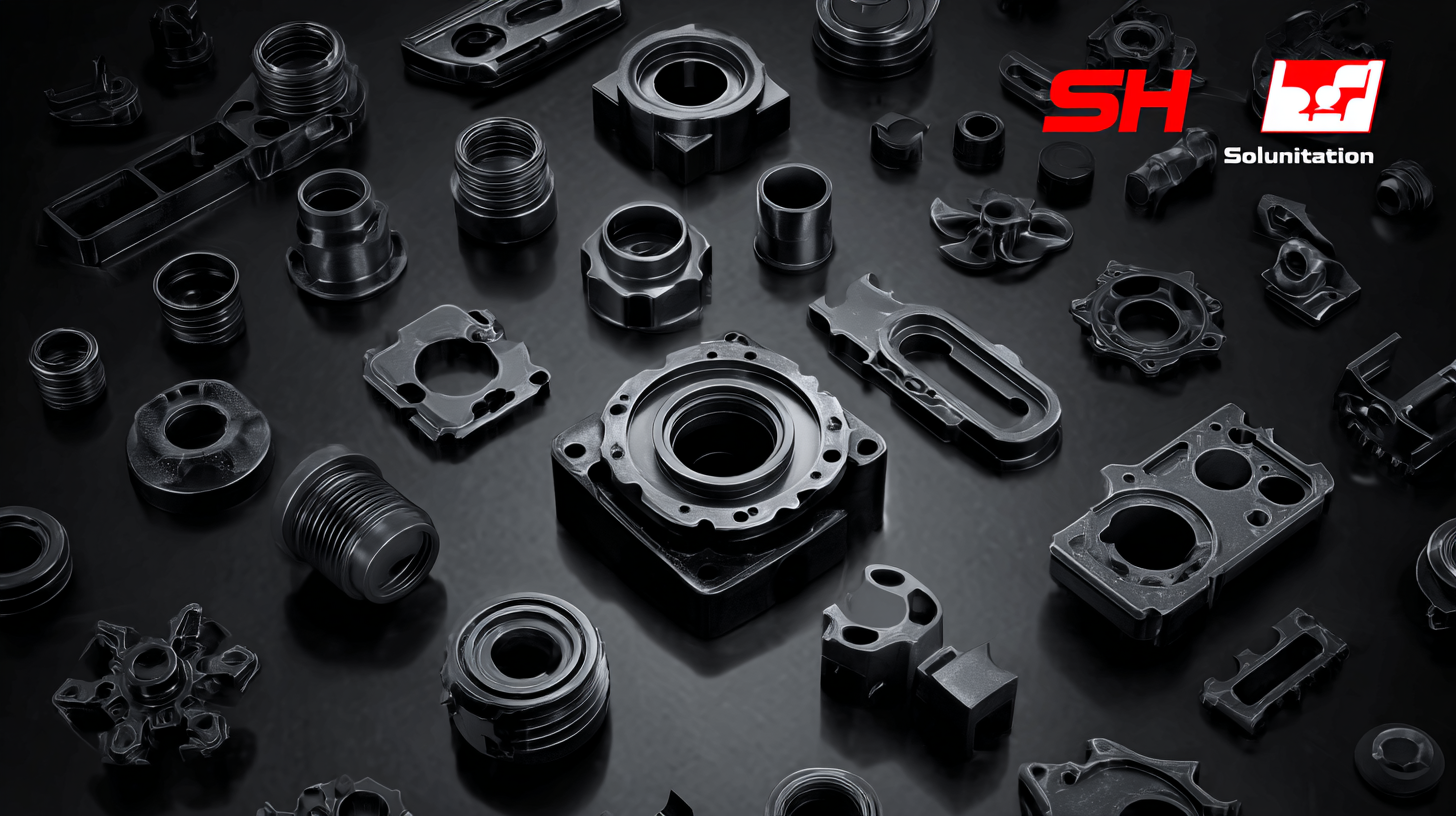

When sourcing high-quality injection molding manufacturers for motorcycle parts, several key factors must be considered to ensure optimal performance and reliability.

First and foremost, it is essential to evaluate the manufacturer's experience and expertise in the industry. A company with a proven track record in producing motorcycle components will likely possess the knowledge and technical skills necessary to meet rigorous quality standards.

Additionally, the materials used in the injection molding process play a crucial role in the durability and performance of the parts. Manufacturers that utilize advanced materials and technologies can provide a distinct advantage in terms of strength, weight, and resistance to wear and tear. It is advisable to inquire about the types of polymers employed and the production techniques utilized, as these elements significantly impact the final product's quality.

Lastly, the manufacturer's commitment to quality control and testing should not be overlooked. A robust quality assurance process ensures that every part produced meets the required specifications and can withstand the demands of motorcycle operation. By focusing on these key factors, companies can identify the best injection molding manufacturers to enhance their motorcycle parts and overall performance.

In the realm of motorcycle parts manufacturing, the selection of materials plays a crucial role in enhancing performance and reliability. Recent studies indicate that approximately 70% of the performance attributes in motorcycle components can be directly linked to the materials used in their production. High-performance thermoplastics, composites, and alloys have gained traction due to their advantageous mechanical properties. For instance, injection molding technology allows for precision in creating parts that require specific tensile strength and impact resistance, essential for high-speed motorcycles.

Moreover, the motorcycle industry is increasingly leaning towards materials that offer weight reduction without compromising strength. A report from the Motorcycle Industry Council highlights that a reduction of just 10% in weight can lead to a performance enhancement of up to 5% in speed and fuel efficiency. Utilizing advanced polymers can help manufacturers achieve this balance, promoting not only performance improvements but also sustainability through lightweight designs. As the motorcycle market evolves, materials science remains at the forefront, underscoring the necessity of meticulous selection in fabricating parts that meet rigorous safety and performance standards.

When sourcing injection molding motorcycle parts, evaluating manufacturer capabilities is crucial for ensuring performance and reliability. Key technology and equipment considerations include the extent of automation in the manufacturing process and the sophistication of the molding technologies used. Reports indicate that manufacturers are increasingly prioritizing investments in digital solutions to enhance operational efficiency. Specifically, data gathered from industry studies shows a notable trend towards integrating advanced technologies, which have the potential to reduce production time and increase precision—qualities essential in the competitive motorcycle parts market.

Tip: Look for manufacturers that utilize cutting-edge equipment, as this often correlates with higher quality outputs. Additionally, focus on those that demonstrate a commitment to continuous improvement and training, which can help address the ongoing skills gap in the industry.

Understanding the economic and financial health of your suppliers also plays a pivotal role in mitigating risks and ensuring sustainability. An assessment of suppliers’ economic standing provides insights into their ability to deliver consistently over time. As highlighted in recent industry reports, manufacturers are advised to conduct thorough evaluations to ensure reliability and minimize disruptions, especially in the fast-paced motorcycle parts market.

Tip: Always request financial reports and capacity assessments from potential suppliers. This proactive approach can help you identify partners capable of meeting your performance standards while enhancing your supply chain resilience.

When sourcing injection molding motorcycle parts, assessing quality control processes is crucial to ensure product reliability. Effective quality control begins with the selection of raw materials, where manufacturers must adhere to industry standards to guarantee that the plastic and other components are durable and fit for purpose. Additionally, utilizing advanced materials that exhibit superior resistance to wear and environmental factors can significantly enhance the overall performance of motorcycle parts.

Once the materials are in place, manufacturers should implement rigorous testing protocols throughout the production cycle. These tests can include dimensional inspections, mechanical testing, and stress analyses to ensure each part can withstand the demands of high-performance motorcycle operation. Employing statistical process control (SPC) methods can also help monitor production variations in real-time, allowing for immediate corrective actions if any discrepancies arise. By establishing a thorough quality assurance process, manufacturers can deliver motorcycle parts that not only enhance performance but also foster trust and reliability among consumers, ultimately contributing to greater customer satisfaction and brand loyalty.

Building strong supplier relationships is crucial when sourcing injection molding motorcycle parts to enhance both performance and reliability. Collaborating with suppliers who understand the nuances of motorcycle design and manufacturing can lead to innovative solutions and improved product quality. By establishing clear communication and aligning goals, manufacturers can optimize their injection molding processes, resulting in parts that meet the exacting standards of the motorcycle industry.

Long-term partnerships with reliable suppliers also provide the benefit of consistency in quality and supply chain stability. These relationships foster trust and enable suppliers to better understand the specific needs of their clients. As a result, they can tailor their offerings, anticipating future needs and potential challenges. This proactive approach not only enhances the performance of motorcycle parts but also reduces downtime and accelerates production timelines, ensuring that manufacturers can meet market demands effectively.