The automotive industry in China is undergoing a significant transformation, driven by advancements in technology and changing consumer demands. Among these developments, China Automotive Plastic Injection Molding has emerged as a crucial process, enabling manufacturers to produce high-quality, lightweight, and durable automotive parts efficiently. As we delve into the top ten insights of 2023, it becomes evident that this molding process is not only revolutionizing production techniques but also enhancing the overall performance and sustainability of vehicles in the market.

In recent years, the focus on electric vehicles and eco-friendly materials has further fueled innovations within the China Automotive Plastic Injection Molding sector. This article will explore how new materials and technologies are being integrated into the molding processes, leading to greater design flexibility and cost-efficiency. Additionally, we'll highlight the importance of adopting advanced automation and digital solutions, which are transforming traditional manufacturing into smart, responsive production lines aligned with the emerging trends in the automotive industry, thus positioning China at the forefront of global automotive manufacturing.

In 2023, the automotive plastic injection molding industry in China is experiencing significant transformation driven by advancements in technology and evolving consumer preferences. One of the key trends this year is the increasing use of lightweight materials. According to a recent industry report, the demand for lightweight components is projected to grow by over 15% annually, as manufacturers strive to meet stricter fuel efficiency standards and enhance vehicle performance. As a result, the integration of engineered plastics in vehicle designs is becoming commonplace, which not only reduces weight but also boosts fuel efficiency.

Another notable trend is the push for sustainability. With rising awareness of environmental issues, the industry is seeing a shift toward using recyclable and bio-based plastics. Data indicates that the market for sustainable materials in automotive applications is expected to expand by 20% in the next five years. Companies are beginning to implement circular economy practices, focusing on reducing waste during production and increasing the lifespan of automotive parts through recycled materials.

Tips: To remain competitive in this evolving market, automotive manufacturers should prioritize research and development of innovative materials that not only meet regulatory requirements but also cater to consumer preferences for sustainability. Additionally, investing in advanced injection molding technologies can enhance efficiency and reduce production costs, ensuring a robust position in this dynamic industry.

In 2023, the automotive industry in China is undergoing significant transformation driven by stringent environmental regulations. These regulations are aimed at reducing emissions and promoting sustainable practices within automotive manufacturing, particularly in the domain of plastic injection molding. As a result, manufacturers are increasingly adopting eco-friendly materials and innovative production techniques that minimize their carbon footprint. The shift not only enhances compliance with government mandates but also positions companies to meet the rising consumer demand for sustainable vehicles.

The impact of environmental regulations extends beyond mere compliance; it fundamentally reshapes production processes. Firms are investing in advanced technologies that facilitate recycling and the use of biodegradable plastics. Moreover, collaboration among stakeholders in the supply chain is becoming crucial as producers seek to align their practices with environmental standards. This cooperative approach not only fosters innovation but also enhances efficiency and reduces waste. As the industry moves forward, the integration of these environmental considerations is expected to redefine the competitive landscape, placing a premium on sustainability in automotive plastic production.

The automotive industry in China is experiencing a significant transformation, primarily driven by technological advancements in plastic injection molding. As manufacturers seek to optimize production efficiency and reduce costs, innovative approaches are emerging. New materials, specifically engineered for durability and lightweight properties, are shaping the future of vehicle design and functionality. Enhanced injection molding techniques enable the creation of complex geometries that were previously challenging, resulting in improved performance and aesthetics of automotive components.

Tips for enhancing your injection molding processes include investing in automation technologies that expedite production cycles while maintaining high-quality standards. Integrating advanced software for simulation and design can help predict potential challenges, allowing manufacturers to streamline operations. Additionally, leveraging data analytics can provide insights into production efficiency, leading to better decision-making and resource allocation.

The use of sustainable materials is also gaining traction, with manufacturers exploring bio-based plastics and recycled materials to meet growing environmental concerns. These innovations not only support eco-friendly initiatives but also align with consumer demand for greener vehicles. Implementing practices that emphasize sustainability may become a competitive advantage in the evolving automotive landscape in China.

| Insight | Description | Impact Level | Technological Trend |

|---|---|---|---|

| Increased Use of Bioplastics | Growing adoption of environmentally friendly materials in automotive parts. | High | Sustainable Manufacturing |

| Advanced Molding Techniques | Technologies such as multi-material and 3D injection molding are on the rise. | Medium | Innovative Manufacturing |

| Automation in Injection Molding | Increased automation to enhance production efficiency and reduce costs. | High | Industry 4.0 |

| Customization Capabilities | Growing demand for customized automotive parts to cater to consumer preferences. | Medium | Flexible Manufacturing |

| Reduction of Cycle Times | Advancements in technology are leading to shorter cycle times for injection molding processes. | High | Efficiency Improvements |

| Integration of AI and IoT | Utilization of AI and IoT for predictive maintenance and real-time monitoring. | High | Smart Manufacturing |

| Enhanced Quality Control | Incorporation of advanced quality control measures for better consistency. | Medium | Quality Management |

| Growth in Electric Vehicle Parts | Increase in automotive plastic parts specifically designed for electric vehicles. | High | Electric Mobility |

| Circular Economy Practices | Adoption of recycling processes within the injection molding framework. | Medium | Sustainable Development |

| Investment in R&D | Increased investments in research and development to foster innovation. | High | Innovation Focus |

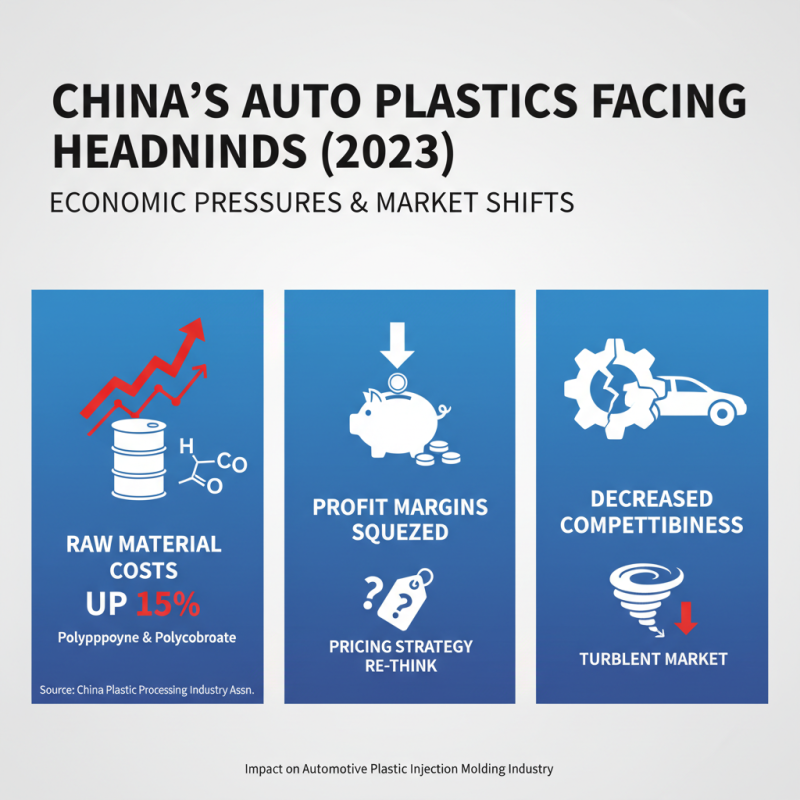

The automotive plastic injection molding industry in China faces significant challenges in 2023, driven by a combination of economic pressures and evolving market dynamics. One of the primary issues is the rising cost of raw materials. According to a recent report by the China Plastic Processing Industry Association, the prices of key materials such as polypropylene and polycarbonate have surged by approximately 15% over the past year. This increase not only affects profit margins for manufacturers but also compels them to reconsider pricing strategies, often leading to a potential decrease in competitiveness in an already turbulent market.

Another pressing challenge is the shift towards sustainable practices within the automotive sector. With the Chinese government's commitment to reducing carbon emissions, manufacturers are under pressure to adopt more eco-friendly materials and processes. A study from the International Energy Agency noted that up to 35% of automotive parts could potentially need to use recycled materials or bioplastics by 2030 to meet regulatory requirements. Consequently, this shift demands significant investment in new technologies and processes, which may be a logistical and financial hurdle for many plastic manufacturers who are still recovering from the impacts of the COVID-19 pandemic. The complexity of these transitions highlights the urgency for innovation and adaptation within the industry to align with both consumer expectations and regulatory changes.

The automotive industry is undergoing rapid transformation driven by technological advancements and evolving consumer preferences. In 2023, automotive plastic injection molding is set to experience significant growth, especially in the context of electric vehicles (EVs) and lightweight material requirements. As manufacturers increasingly prioritize sustainability and efficiency in design, the demand for high-performance plastic components will continue to rise. Companies that can leverage innovative molding techniques and materials will find ample opportunities to enhance vehicle functionality while meeting stringent regulatory standards.

Additionally, the push towards electrification and autonomy opens new avenues for plastic injection molding applications. With the integration of advanced electronics and infotainment systems in vehicles, there is a growing need for intricate plastic parts that ensure safety and user-friendliness. Investing in research and development to produce high-quality, durable components will be crucial. Further, as global supply chains stabilize, manufacturers can explore collaborations and partnerships to drive technological advancements, streamline operations, and expand their market reach. The focus will increasingly shift to not only meeting current demands but also anticipating future market trends and consumer needs within the automotive sector.