Choosing the right method for manufacturing automotive components is crucial for ensuring quality, efficiency, and cost-effectiveness in any automotive project. Among various manufacturing techniques, Custom Automotive Plastic Injection Molding stands out as a preferred choice for producing intricate and durable plastic parts tailored to specific requirements. This method not only allows for a high level of customization but also supports the production of complex shapes that meet the demands of modern automotive designs.

As the automotive industry continues to evolve, the need for lightweight, strong, and precise components becomes increasingly important. Custom Automotive Plastic Injection Molding provides the flexibility to collaborate closely with engineers and designers to create parts that not only fit perfectly but also enhance the overall performance and aesthetics of the vehicle. By understanding the intricacies of this molding process, project leaders can make informed decisions that align with their objectives and budget considerations.

In this guide, we will explore the key factors to consider when selecting Custom Automotive Plastic Injection Molding for your projects. From material selection to the advantages of precision molding techniques, understanding these elements will empower you to optimize your automotive component manufacturing for superior results.

Custom automotive plastic injection molding is a pivotal process in the production of vehicle components, allowing for the creation of complex shapes and intricate designs suited for various automotive applications. This method utilizes high-quality plastic materials to produce parts that are both durable and lightweight, essential for enhancing vehicle performance and efficiency. Understanding the basics of this technology is crucial for anyone looking to embark on a project involving automotive parts manufacturing.

The process begins with the creation of a custom mold, which is designed based on specific part dimensions and functionality. High temperatures and pressures are then applied to inject molten plastic into the mold, where it cools and solidifies, resulting in a finished product with precise specifications. The versatility of custom automotive plastic injection molding means that it can accommodate a wide range of materials and colors, enabling manufacturers to create parts that not only meet functional requirements but also aesthetic standards. By grasping these foundational elements, project managers can make informed decisions about materials, designs, and manufacturing processes to ensure the success of their automotive projects.

When selecting injection molding materials for automotive applications, several key factors must be carefully considered to ensure the final product meets both performance and aesthetic requirements. Firstly, the mechanical properties of the materials are crucial. Factors such as tensile strength, impact resistance, and flexibility should align with the intended use of the automotive part. For instance, components that require high durability may benefit from materials with enhanced strength characteristics, while those that need to flex or bend might opt for more pliable options.

Another vital consideration is the thermal stability of the injection molding materials. Automotive parts often experience significant temperature fluctuations, so choosing materials that can withstand high temperatures without degrading is essential. Additionally, resistance to chemical exposure from automotive fluids, such as oil and fuel, must not be overlooked, as these substances can adversely affect both the appearance and longevity of the components. Lastly, environmental impact should also influence material selection; biodegradable or recyclable options can be beneficial for sustainability-focused projects, aligning with contemporary shifts towards greener manufacturing processes.

When embarking on a custom automotive plastic injection molding project, evaluating design specifications is crucial. Automotive components often necessitate precise dimensions and tolerance to ensure optimal performance and safety. Designers must collaborate closely with engineers and manufacturers to understand the necessary requirements, which can include factors like weight reduction, thermal stability, and resistance to harsh environments. These specifications are fundamental in guiding the material selection and molding process, ensuring that the final product meets industry standards and customer expectations.

**Tips:** Always begin with a comprehensive requirements checklist that outlines all necessary specifications, including mechanical properties and environmental compliance. This roadmap will serve as a guide throughout the design process, minimizing potential pitfalls.

Additionally, consider prototyping early in the design phase. Creating a prototype allows for testing and validation of both the design and material selection before mass production kicks off. This step can save time and costs by identifying issues in functionality or structural integrity that may arise during actual use in automotive applications.

**Tips:** Utilize simulation software to predict performance and manufacturing challenges. This technology can significantly streamline the development process by enabling adjustments before physical production, leading to more efficient project timelines.

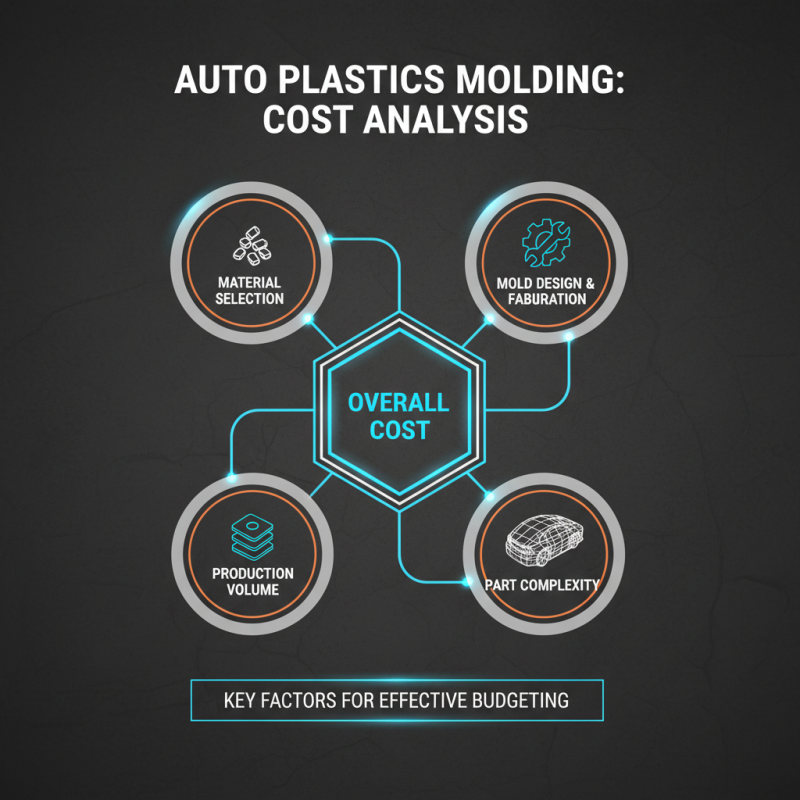

When embarking on custom automotive plastic injection molding projects, it is essential to conduct a thorough cost analysis to ensure effective budgeting. The first step in this process involves identifying the key factors that influence the overall cost. These factors typically include material selection, mold design and fabrication, production volume, and the complexity of the parts being manufactured. Understanding each of these components can help to create a clear financial plan and prevent unexpected expenses down the line.

Material selection plays a crucial role in determining the cost of your project, as various plastics come with different price points and properties. Additionally, the intricacies involved in mold design can significantly affect initial production costs; more complex molds generally require higher upfront investment, but they can result in cost savings during mass production. Therefore, balancing these elements based on project requirements is vital. By properly estimating these costs and including contingencies for unforeseen challenges, businesses can position themselves for success in their custom injection molding endeavors.

When selecting a manufacturer for custom automotive plastic injection molding, it's crucial to evaluate their capabilities and experience within the industry. A report from MarketsandMarkets indicates that the automotive plastics market is expected to reach $19.4 billion by 2024, highlighting the growing demand and competition in this field. Manufacturers with proven expertise in high-quality injection molding can greatly impact the success of your project, ensuring the parts meet stringent automotive standards.

One of the key considerations is the manufacturer's production capacity and technology. Advanced machinery and skilled labor are essential for efficient production and consistent quality. Look for companies that employ state-of-the-art techniques, such as robotic automation and high precision molding technologies, which can improve turnaround times and reduce defects. Additionally, inquire about their quality assurance processes, as robust measures can help mitigate risks associated with part failures.

**Tips:**

- Always check the manufacturer's certifications and past project samples to gauge their quality.

- Consider their ability to offer design support, as collaboration in the early planning stages can lead to reduced costs and optimal part performance.

- Evaluate their customer service and support throughout the manufacturing process, as reliable communication can significantly enhance your project's efficiency.