In the ever-evolving landscape of manufacturing, understanding "Custom Plastic Injection Molding" is crucial. As industries demand greater efficiency and precision, the choice of molding techniques becomes paramount. According to a report by Grand View Research, the global plastic injection molding market is expected to reach $453.5 billion by 2026. This growth signifies the importance of selecting the right approach for projects.

Expert John Smith, a leading figure in the injection molding industry, emphasizes, "Choosing the right custom molding option can significantly impact production efficiency and product quality." His insights reflect a growing recognition that not all injection molding services are created equal. Businesses often overlook critical factors, such as material compatibility and design intricacies, which can lead to significant setbacks.

Failing to carefully choose your custom plastic injection molding partner can result in costly errors. Even slight miscalculations in design specifications can lead to production delays. Therefore, reflecting on these choices is essential for success. The right decision can enhance not only functionality but lifespan and sustainability of the product.

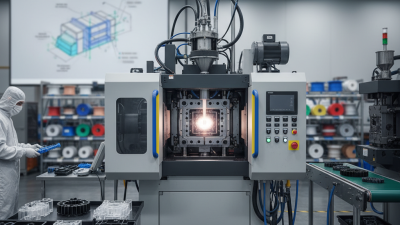

Custom plastic injection molding is a versatile process. It's essential to understand the basics before starting your project. This method involves creating plastic parts by injecting molten resin into a mold. The molten plastic cools and hardens, forming a desired shape. This process can create complex geometries with high precision and repeatability.

Choosing custom plastic injection molding requires careful consideration. Many factors come into play, such as material selection and mold design. Not all materials are alike. Some are more durable, while others offer flexibility. The choice directly impacts the product's performance. You might ponder the design complexity. A more intricate design can lead to higher costs and longer lead times.

Quality control is vital throughout the process. Monitoring the injection process ensures consistency. However, sometimes defects occur. Scratches or imprecise dimensions can happen, leading to setbacks. It's crucial to have a plan for addressing these issues. Adjustments and revisions may be needed during production. Stay adaptable and open to changes to achieve the best results.

When embarking on a custom plastic injection molding project, the first step is to identify your specific requirements. Understanding the purpose of your molded parts is crucial. Are they functional or decorative? This will guide the material selection and design nuances. Consider the end-users and how the components will be utilized. This clarity will help in creating a practical mold.

Tips: Always seek feedback early. Often, initial ideas may not fit reality. Engage with your team or peers to refine your thoughts. Their insights might highlight gaps or opportunities you missed.

Material choice plays a vital role in performance. Different plastics have unique properties. For example, some may offer high durability while others provide flexibility. Analyze the environment your product will face. This could involve exposure to chemicals or extreme temperatures. Balancing quality and cost can be tricky, so don't overlook your budget constraints.

Tips: Prototype quickly. Early tests can reveal unexpected issues. Adjustments made at this stage can save time later on. Don't fear the iterative process; it’s part of refining your vision.

When choosing materials for plastic injection molding, several factors play a crucial role. The type of plastic affects the durability and flexibility of the final product. Different materials offer unique properties. For instance, ABS provides impact resistance. On the other hand, polycarbonate offers excellent clarity and toughness. Understanding these characteristics is vital.

Moreover, you might find yourself overwhelmed with choices. The sheer variety can lead to indecision. It’s crucial to match your project’s needs with the right material. Consider environmental conditions, such as temperature and moisture exposure. These factors could significantly impact the performance of your product.

Testing prototypes is equally essential. Manufacturing a small batch allows evaluation of material performance. Sometimes, the expected results may differ from the actual performance. Reflecting on these outcomes helps refine the selection process. It can save time and resources in the long run. Always be ready to re-evaluate your options, as new materials emerge in the market.

When selecting a manufacturer for custom plastic injection molding, capabilities vary significantly. Key factors include machinery, materials used, and production capacity. A recent industry report shows that 70% of manufacturers have upgraded their machinery in the last five years. This modernization allows for faster production times and improved precision.

However, not all manufacturers prioritize quality over quantity. A survey indicates that 45% of companies face challenges in maintaining consistent quality due to inadequate quality control measures. It’s crucial to assess a manufacturer’s quality assurance processes. This helps ensure that products meet your project's specifications and standards.

Additionally, the range of materials offered can impact the final product. Many manufacturers now provide advanced polymer options, with 60% offering bio-based alternatives. Yet, it’s essential to question whether these materials align with your sustainability goals. Understanding the capabilities of different manufacturers can help mitigate risks in your project, ensuring you choose a partner that fits your unique needs.

When embarking on a custom plastic injection molding project, budgeting is crucial. Understanding the costs involved can lead to better decision-making. Here are a few considerations to keep in mind.

Material selection affects cost greatly. Different plastics have varying price points. High-quality materials might be more expensive but could save money in the long run through durability. Also, consider the impact of design complexity. Intricate designs may require specialized molds, increasing initial costs.

Tip: Simplifying designs can help cut costs. Fewer changes during the design phase can avert costly revisions later on.

Another aspect is production volume. Higher production runs can reduce per-unit costs. However, large orders require upfront investment, which can strain budgets. Balancing volume with what you truly need can be challenging.

Tip: Start small. Test the market with lower volumes before committing to larger orders. This approach can prevent significant losses if your product initially underperforms. Remember to factor in shipping and handling costs too. What seems like a good deal might add unexpected expenses.

| Dimension | Specification | Estimated Cost ($) | Lead Time (weeks) |

|---|---|---|---|

| Small Parts | Up to 10cm | $1,000 - $5,000 | 2 - 4 |

| Medium Parts | 10cm to 30cm | $5,000 - $15,000 | 4 - 8 |

| Large Parts | Above 30cm | $15,000 - $50,000 | 8 - 12 |

| Complex Shapes | Varies | $8,000 - $30,000 | 5 - 10 |

| Material Type | ABS, PP, PC, etc. | $2,000 - $10,000 | 3 - 7 |