In the ever-evolving landscape of global manufacturing, Chinese injection plastic parts are setting new standards of excellence, particularly in the automotive sector. As the world's largest automotive market, China is poised to reshape industry benchmarks through innovation and advanced production capabilities. According to a report by Allied Market Research, the global automotive plastic market is projected to reach $52.4 billion by 2024, indicating a significant growth trajectory that underscores the increasing reliance on high-quality plastic parts.

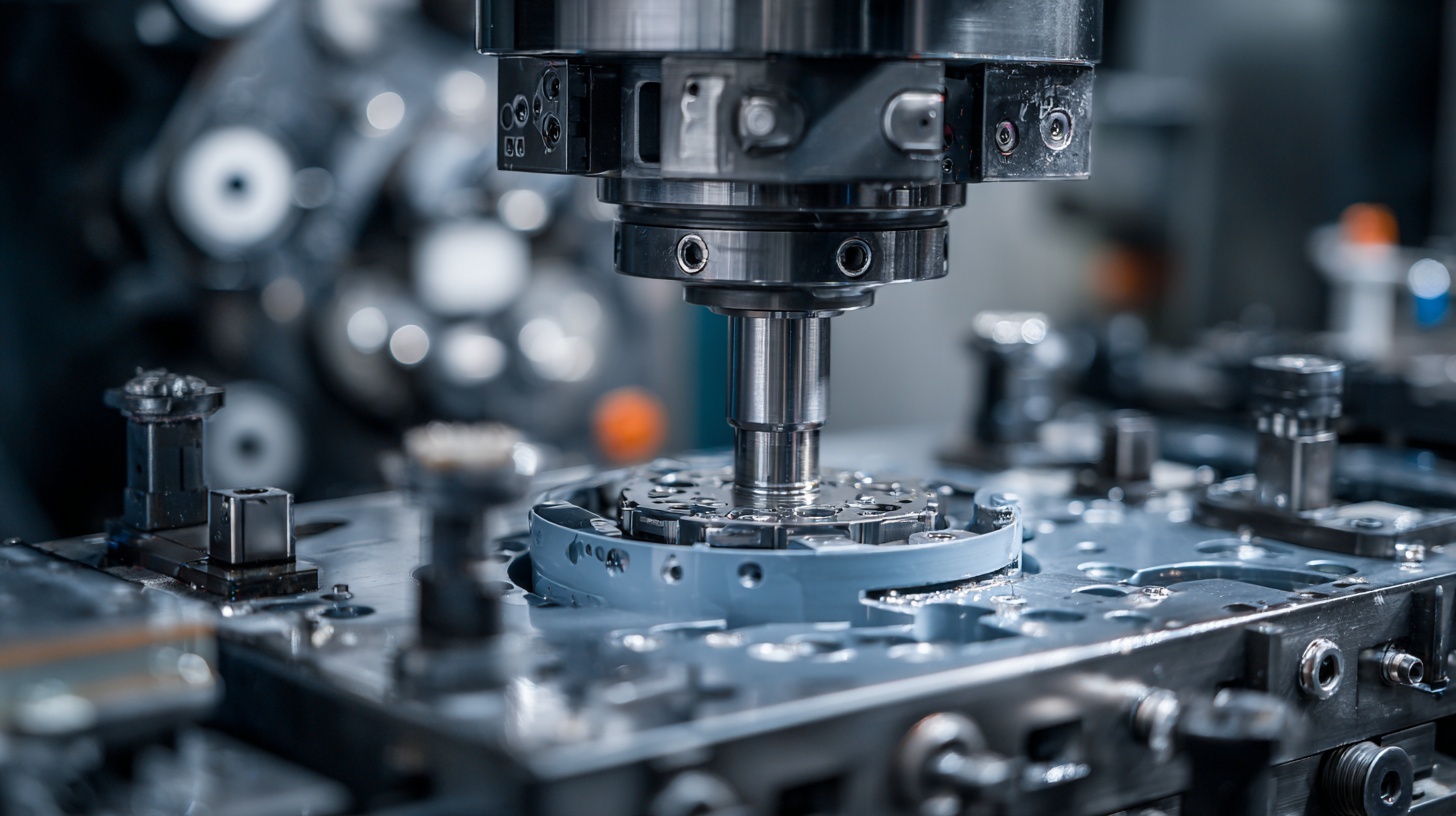

Among the leading players contributing to this growth is the Automotive Exterior Injection Plastic Part Molding Manufacturer segment, which plays a crucial role in enhancing design flexibility and lightweight performance in vehicles. By embracing cutting-edge technologies and adhering to rigorous quality standards, Chinese manufacturers are forging a path toward unrivaled reliability and trust in the global marketplace, ultimately reinforcing the notion that excellence in production is not just an option, but a requisite for success.

China has rapidly established itself as a frontrunner in the global injection plastic manufacturing industry, driven by its robust production capabilities and technological innovation. According to a report by Market Research Future, the global injection molding market is anticipated to grow at a CAGR of approximately 5.8% from 2020 to 2027, with China playing a pivotal role in this expansion. The country's manufacturing prowess, supported by its extensive supply chains and competitive labor costs, enables it to produce high-quality plastic parts at scale, meeting the needs of diverse sectors including automotive, consumer goods, and electronics.

Additionally, the Chinese government has recently invested heavily in advanced manufacturing technologies, such as automation and artificial intelligence, further enhancing the country's capabilities in injection molding. As a result, Chinese manufacturers not only comply with international quality standards but often exceed them, setting new benchmarks for efficiency and reliability. In 2022, it was reported that China's injection plastic market reached a staggering USD 60 billion, showcasing its dominance and influence in the global landscape. With continuous improvements in production techniques and a focus on sustainability, the rise of China as a leader in injection plastic manufacturing is poised to reshape the industry for years to come.

| Category | Description | Statistic | Source |

|---|---|---|---|

| Market Share | Percentage of global injection plastic parts | 30% | Industry Report 2023 |

| Export Growth | Annual growth rate of exports | 15% | Trade Analysis 2023 |

| Production Capacity | Total production capability in tons | 1 million tons | Manufacturing Insights 2023 |

| Sustainability Practices | Commitment to sustainable materials | 60% use of recycled materials | Environmental Report 2023 |

| Innovation Index | Rank in global innovation for manufacturing | Rank 5 | Global Innovation Survey 2023 |

In the realm of global manufacturing, Chinese injection molding has emerged as a significant player, revolutionizing the standards for quality and innovation. A recent market report indicated that the global injection molded plastics market is projected to reach $435 billion by 2028, with China leading the charge due to advancements in production efficiency and technological integration. Key innovations such as the incorporation of Industry 4.0 practices, including IoT and robotics, are enabling manufacturers to enhance precision and reduce lead times, ultimately elevating product quality.

One standout innovation in Chinese injection molding is the use of advanced materials and specialized techniques that address customer-specific requirements. For instance, the introduction of high-performance thermoplastics and bio-based materials is gaining traction in various industries, reflecting a growing demand for sustainability without compromising performance. Moreover, a study by the China Plastics Processing Industry Association revealed that over 60% of manufacturers have adopted smart factory solutions, which not only optimize production workflows but also enhance product consistency. This shift towards

smart manufacturing is setting new benchmarks for quality assurance in injection molded parts, positioning China at the forefront of global standards.

smart manufacturing is setting new benchmarks for quality assurance in injection molded parts, positioning China at the forefront of global standards.

China has solidified its position as a global leader in the manufacturing of injection plastic parts, driven by rigorous adherence to global standards and an unwavering commitment to sustainability. According to a 2022 report by MarketsandMarkets, the global plastic injection molding market is projected to grow from $352.5 billion in 2021 to $458.2 billion by 2026. China's role in this expansion is pivotal, not just in terms of volume but also in setting benchmarks for quality and environmental responsibility.

Chinese manufacturers are increasingly adopting eco-friendly practices, aligning with international sustainability initiatives. For instance, a study from the China National Chemical Corporation indicates that over 70% of leading Chinese plastic manufacturers have implemented sustainable manufacturing processes that reduce emissions and waste. This commitment to environmental stewardship not only meets but often exceeds global standards, giving Chinese injection plastic parts a competitive edge in markets around the world. As companies prioritize sustainability in their supply chains, China’s advancements serve as a model for how industry can balance growth with responsibility, setting a new standard for excellence in manufacturing.

Chinese manufacturers are increasingly adopting eco-friendly practices, aligning with international sustainability initiatives. For instance, a study from the China National Chemical Corporation indicates that over 70% of leading Chinese plastic manufacturers have implemented sustainable manufacturing processes that reduce emissions and waste. This commitment to environmental stewardship not only meets but often exceeds global standards, giving Chinese injection plastic parts a competitive edge in markets around the world. As companies prioritize sustainability in their supply chains, China’s advancements serve as a model for how industry can balance growth with responsibility, setting a new standard for excellence in manufacturing.

The landscape of global manufacturing is witnessing a significant transformation, particularly through the advancements occurring in the Chinese injection plastic parts industry. Technology plays a pivotal role in enhancing manufacturing excellence, with automation and data analytics being central to these advancements.

Notably, a report by Grand View Research anticipates that the global plastic injection molding market size will reach $332.3 billion by 2025, driven by innovations and enhanced production techniques that Chinese manufacturers are employing.

Chinese manufacturers are increasingly investing in state-of-the-art machinery and smart manufacturing technologies, which have resulted in improved precision and efficiency. For instance, the use of Industrial Internet of Things (IIoT) solutions allows for real-time monitoring and data collection, helping to predict machine maintenance needs and reducing downtime. A study published by McKinsey highlights that implementing advanced manufacturing technologies can improve productivity by up to 30%, setting new benchmarks for quality and production capabilities.

Furthermore, the integration of artificial intelligence (AI) and machine learning is revolutionizing the design and prototyping phases in manufacturing. According to PwC, companies leveraging AI in their manufacturing processes can achieve a 20%-30% reduction in time-to-market for new products. This not only fosters innovation but also enhances competitiveness on a global scale, as Chinese injection plastic parts are beginning to set unparalleled standards in the industry.

Chinese companies are increasingly making waves in global manufacturing, setting new standards that demonstrate their capacity for innovation and excellence. Success stories abound, showcasing how Chinese firms are not just participants but leaders in the competitive landscape of various industries. For instance, advanced AI technologies have emerged from China, where startups are leveraging innovative techniques to challenge established global players. This trend reflects a broader shift in China, where businesses are prioritizing research and development to enhance global competitiveness.

Tips for companies seeking to excel in manufacturing globally include embracing new technologies and focusing on sustainability. Adopting innovative practices can streamline production processes, reducing costs while improving product quality. Additionally, investing in employee training and development ensures that teams are equipped with the latest skills, fostering a culture of continuous improvement and excellence.

Another essential tip is to establish strong partnerships across international markets. Collaborating with global suppliers and partners can enhance distribution networks and expand market reach. By understanding local needs and adapting products accordingly, companies can better meet consumer demands while maintaining the high standards that define successful manufacturing in today's economy.