In the highly competitive automotive industry, achieving efficiency in manufacturing processes is crucial for reducing costs and meeting consumer demand. Automotive Injection Molding has emerged as a preferred method for producing intricate components with precision and speed. According to a recent report from MarketsandMarkets, the global automotive injection molding market is projected to reach $39.3 billion by 2026, driven by the growing demand for lightweight materials and the push for more innovative designs in vehicle manufacturing.

However, many manufacturers still grapple with inefficiencies that hinder their productivity. By implementing strategic improvements, it’s possible to enhance Automotive Injection Molding efficiency by up to 30 percent. In this blog, we will outline five essential tips that can help automotive manufacturers streamline their processes, reduce waste, and ultimately boost their bottom line.

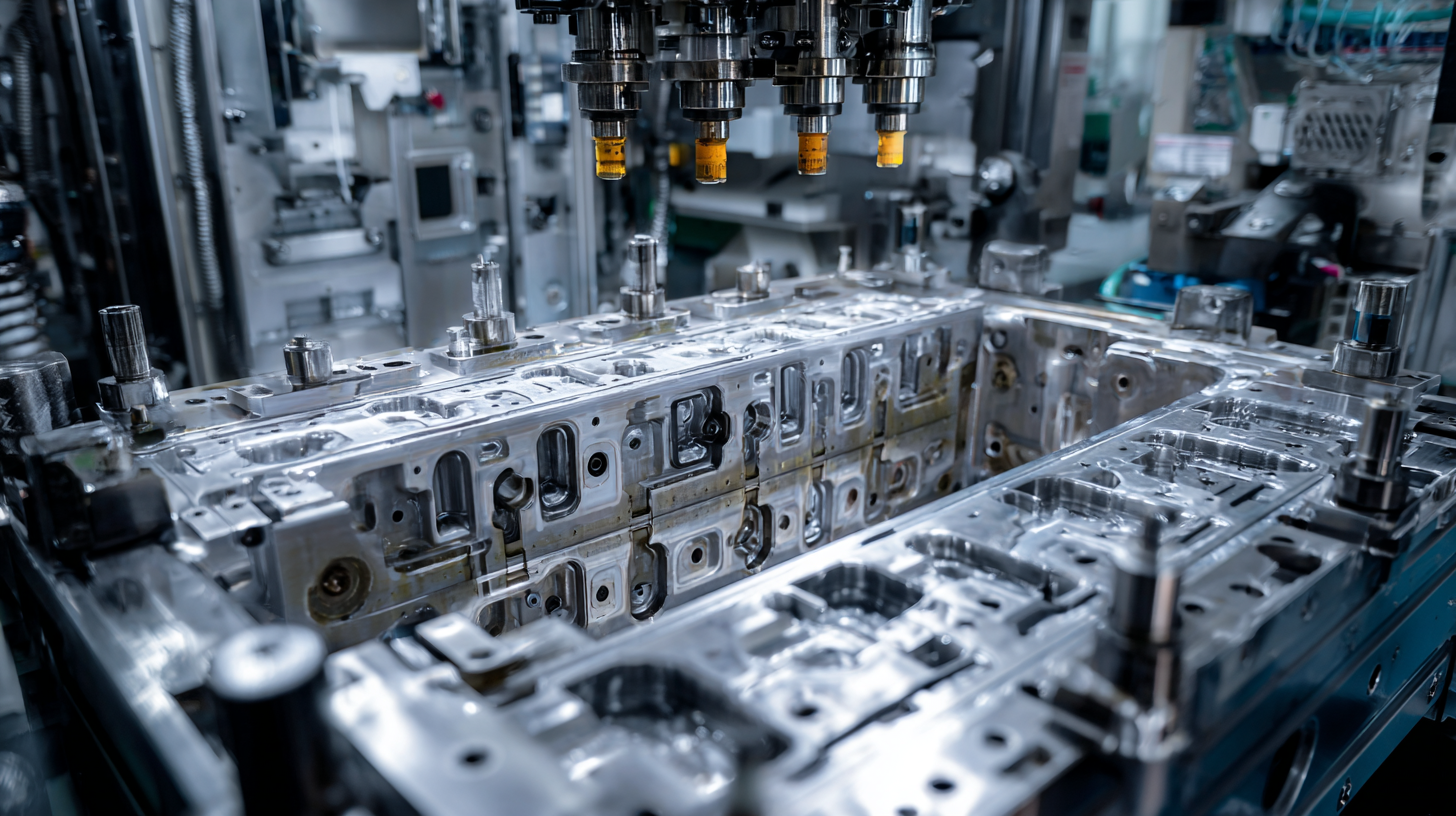

In the automotive industry, optimizing injection molding processes is crucial to improving efficiency and reducing cycle times. Recent advancements in technology have proven to significantly enhance production capabilities. By integrating best practices such as reducing material waste, improving machine maintenance, and leveraging real-time data analytics, manufacturers can expect to reduce cycle times by up to 20%. This not only streamlines production workflows but also allows for a quicker response to market demands.

Additionally, companies can look to successful case studies from other sectors for inspiration. For instance, organizations have seen cycle time reductions of around 30% through the implementation of improved software solutions and performance optimization techniques. By adopting a proactive approach towards technology integration and continuous process evaluation, automotive manufacturers can enhance their injection molding efficiency while achieving substantial cost savings. Embracing these innovative practices will be essential for maintaining a competitive edge in the rapidly evolving automotive landscape.

In the evolving landscape of automotive manufacturing, leveraging

advanced materials is key

to achieving significant production efficiencies. By integrating

high-performance polymers

and composites, companies can not only enhance the durability of components

but also reduce cycle times. Materials such as thermoplastics

or reinforced composites can withstand higher temperatures and

pressures, enabling more efficient processing and reducing the need for

post-production treatments.

One essential tip for manufacturers is to conduct a

thorough analysis of

material properties before selection. Understanding the thermal and mechanical

characteristics can help in choosing the right materials that complement the

injection molding process, leading to a potential 15% boost in

production efficiency. Additionally, optimizing the design for manufacturability can further enhance results by reducing waste and improving flow during the injection process.

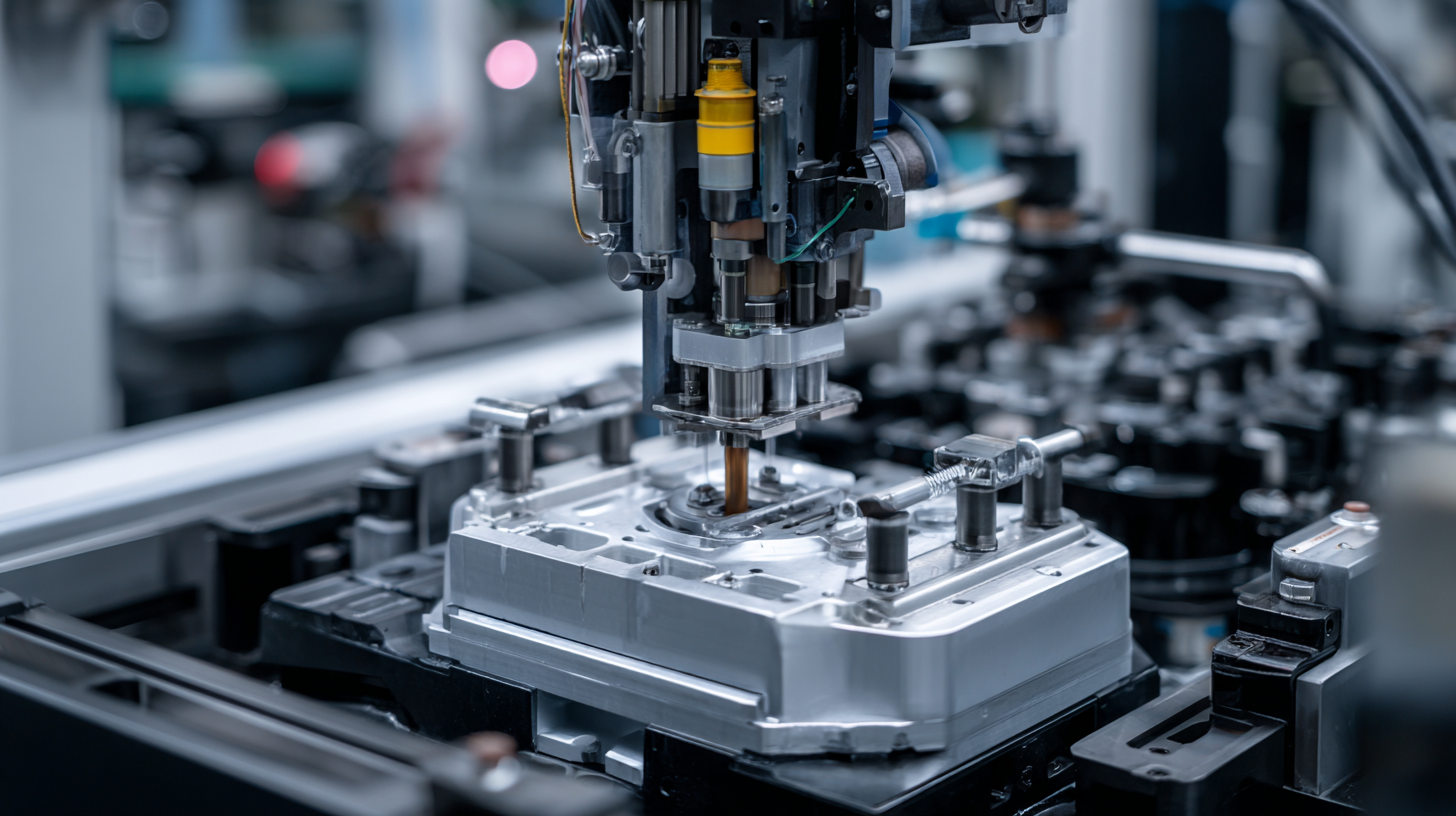

Another effective strategy is to implement

real-time monitoring systems

that track material performance during production. This ensures quick

adjustments in processing parameters, thereby minimizing defects and enhancing

the overall quality of the end product. By focusing on these advanced materials

and employing smart manufacturing techniques, automotive companies

can not only streamline their operations but also significantly increase their

efficiency.

In the rapidly evolving automotive industry, enhancing injection molding performance is crucial for maintaining a competitive edge. Implementing real-time monitoring systems can lead to significant improvements, with potential boosts in efficiency by up to 25%. These systems allow manufacturers to track key performance indicators (KPIs) continuously, enabling them to identify bottlenecks and address issues as they arise. By integrating sensors and data analytics into the injection molding process, companies can make informed decisions based on real-time data, leading to faster response times and reduced downtime.

Moreover, real-time monitoring systems facilitate predictive maintenance, which can prevent unexpected breakdowns and costly production halts. By analyzing data trends and equipment performance, manufacturers can schedule maintenance at optimal times, ensuring machinery operates smoothly. This proactive approach not only enhances production efficiency but also extends the lifespan of equipment. As the automotive sector faces increasing demands for quality and speed, investing in advanced monitoring technologies is becoming essential for companies aiming to improve their injection molding processes and achieve higher productivity levels.

In the competitive automotive industry, maximizing machine utilization rates in injection molding facilities is crucial for enhancing efficiency and profitability. According to a report by the Society of Plastics Engineers, optimizing machine utilization can lead to productivity improvements of up to 30%. This significant enhancement is often achieved by implementing data-driven strategies that focus on predictive maintenance and process optimization. By utilizing advanced sensors and IoT technology, manufacturers can monitor machine performance in real time, anticipating breakdowns before they occur and minimizing downtime.

Additionally, refining production scheduling techniques can significantly boost utilization. Utilizing lean manufacturing principles, such as just-in-time (JIT) production, can help align manufacturing schedules with demand, reducing idle time. Data from the Plastic Industry Association indicates that companies that adopt effective scheduling systems see an increase in operational efficiency, with a potential reduction in lead times by up to 25%. Integrating these strategies can help automotive manufacturers not only enhance their production efficacy but also remain agile in the face of industry fluctuations.

In the competitive landscape of automotive manufacturing, efficiency is key. Utilizing data analytics to identify and address bottlenecks can significantly boost injection molding efficiency by an impressive 30%. According to a recent report from the Society of Automotive Engineers (SAE), manufacturers that leverage data analytics see operational improvements and reductions in cycle times by up to 25%. Implementing real-time data monitoring systems allows for rapid identification of inefficiencies, enabling manufacturers to stay ahead of the curve.

To maximize efficiency, consider the following tips: First, adopt predictive maintenance strategies by analyzing machine performance data. Research indicates that predictive maintenance can reduce downtime by as much as 50%, as noted in a McKinsey report on manufacturing optimization. Second, streamline production workflows by utilizing simulation tools to model different scenarios and identify potential bottlenecks before they occur. This proactive approach can lead to smoother operations and minimize costly delays, enhancing overall productivity.

Lastly, invest in employee training programs focused on data interpretation skills. A strong emphasis on understanding data insights can empower your team to make informed decisions that drive efficiency. Companies that prioritize continuous employee development report a 20% increase in operational performance as highlighted in a study by the Massachusetts Institute of Technology (MIT). By harnessing the power of data analytics, automotive manufacturers can not only improve injection molding efficiency but also position themselves for sustainable growth in the industry.

This chart illustrates the significant improvement in automotive injection molding efficiency after implementing data analytics to identify and address bottlenecks, resulting in a 30% increase in efficiency.