As the injection molding industry continues to evolve, the importance of efficient part design cannot be overstated. According to a recent report by Market Research Future, the global injection molding market is expected to reach $410 billion by 2025, with a compound annual growth rate (CAGR) of 4.5%. This growth is largely driven by advancements in manufacturing technologies and the increasing demand for precision-engineered components across various sectors, including automotive, consumer goods, and medical applications. To stay competitive, companies must prioritize Injection Molding Part Design, optimizing their design processes to enhance productivity and reduce costs. By implementing strategic approaches such as advanced simulation techniques and materials optimization, businesses can significantly improve design efficiency and meet the rising demands of the market. In this blog, we will explore top strategies for enhancing injection molding part design efficiency, paving the way for innovation and success in the industry.

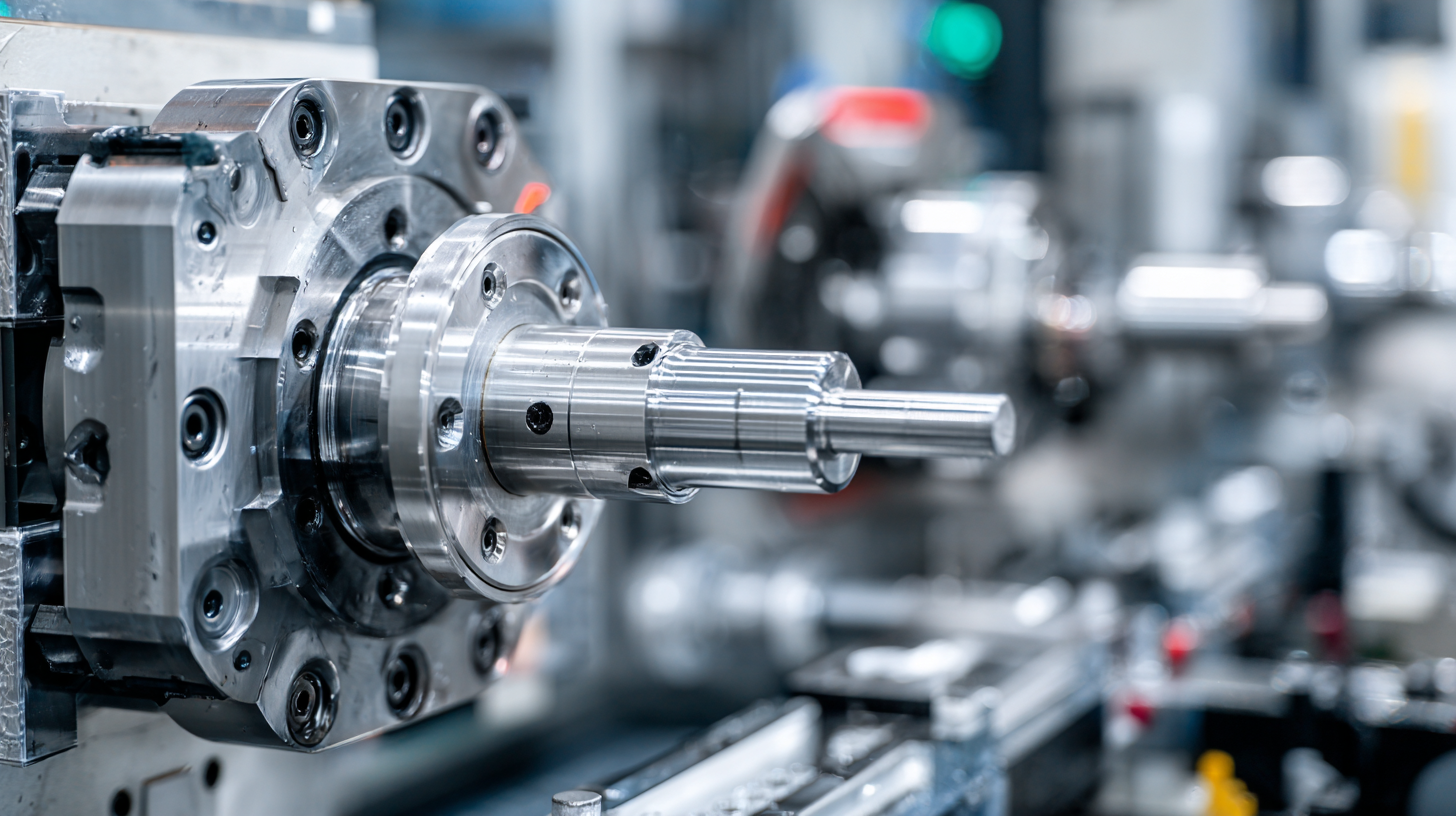

Understanding the basics of injection molding part design is crucial for maximizing efficiency and achieving high-quality production outcomes. Injection molding is a manufacturing process widely used across various industries, accounting for approximately 30% of the plastic industry’s output, as reported by the American Plastics Council. This process involves creating parts by injecting molten material into a mold, which solidifies, thus forming the desired shape. A well-thought-out part design can significantly reduce cycle times and material wastage, leading to cost savings of up to 20%.

A vital aspect of effective design is material selection, which has a direct impact on the final product's performance and manufacturability. According to a study by the Society of Plastics Engineers, approximately 60% of defects in molded parts can be traced back to issues arising from poor material choices. Additionally, implementing design for manufacturability (DFM) principles during the design stage can streamline the production process. By simplifying shapes and avoiding unnecessary complexity, designers can improve mold filling and cooling efficiencies, potentially reducing the time to market by 30%. Understanding these fundamental concepts not only boosts design efficiency but also enhances overall production reliability and quality.

This chart displays the effectiveness of various strategies in enhancing injection molding part design efficiency.

Injection molding is a complex process that heavily relies on efficient part design. To enhance design efficiency, several key factors must be considered. Firstly, material selection plays a crucial role. Choosing the right material can impact not only the strength and durability of the part but also the ease of manufacturing. It is important to select materials that offer the right balance between performance requirements and processing capabilities.

Another significant factor influencing design efficiency is the geometry of the part. Simplicity is vital; designs that are overly complicated can lead to increased manufacturing time and costs. Keeping the design streamlined can facilitate easier mold creation and optimize material flow during the injection process. A useful tip is to focus on uniform wall thickness to avoid issues like warping and to enable consistent cooling throughout the part.

Additionally, collaboration between designers and engineers early in the design phase can greatly improve efficiency. Open communication can help identify potential issues before they escalate, leading to faster iterations and a smoother development process. Regularly revisiting and revising designs based on feedback can mitigate costly delays.

| Design Factor | Influence on Efficiency | Strategies to Enhance | Importance Level (1-5) |

|---|---|---|---|

| Material Selection | Affects flow properties and cycle times | Choose high-performance materials | 5 |

| Part Geometry | Impacts mold design and production speed | Optimize for manufacturability | 4 |

| Draft Angles | Facilitates easier part removal | Incorporate adequate draft angles | 4 |

| Wall Thickness | Affects cooling time and strength | Maintain uniform thickness | 5 |

| Tolerances | Critical for fit and function | Specify realistic tolerances | 5 |

| Mold Design | Directly affects cycle time and quality | Utilize advanced simulation tools | 5 |

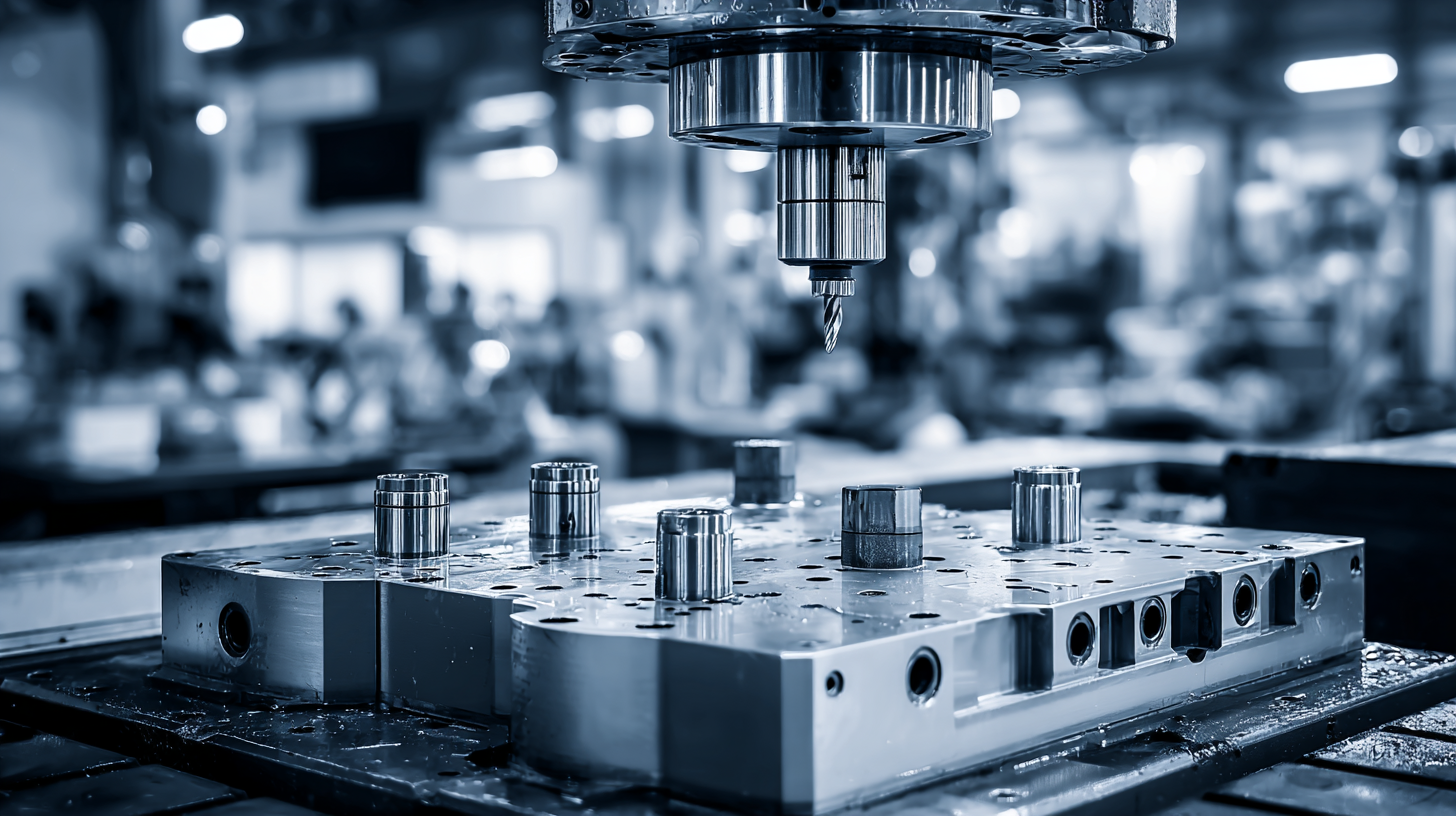

In the realm of injection molding, optimizing mold flow is crucial for enhancing part design efficiency. One innovative technique involves using advanced simulation software to predict and visualize how the molten material travels through the mold. This preemptive approach not only saves time during the prototyping phase but also helps identify potential flow issues, allowing for quick adjustments before the physical mold is created.

Tip: Always consider the gate location and size, as these factors can significantly influence the flow of material. Proper gate positioning can help achieve uniform fill patterns, reducing the risk of defects such as short shots or warping.

Another effective strategy is the application of design for manufacturability (DFM) principles. By designing parts with simpler geometries, you can facilitate smoother flow paths that enhance filling efficiency. Streamlined features, like tapered edges and minimized undercuts, can drastically improve cycle time and reduce production costs.

Tip: Utilize ribbing in your designs to provide additional strength without compromising flow. Ribs can help maintain the structural integrity of the parts while ensuring that the molten material fills the mold evenly.

When it comes to injection molding, the selection of materials plays a pivotal role in determining the efficiency and quality of the final product. A recent study highlights that approximately 70% of production issues can be traced back to improper material selection. With the rise in demand for automotive components like car door inner panels, optimizing the material choice is crucial. For instance, materials that offer excellent flow characteristics and strength-to-weight ratios often lead to improved cycle times and part integrity. Data from industry reports indicate that using advanced polymer blends can enhance impact resistance by up to 30%, significantly affecting the performance of automotive parts.

Moreover, ongoing training in material science and processing techniques is essential for professionals in the plastics industry. A report shows that companies investing in specialized training programs see a 20% increase in productivity and a reduction in waste, which are critical factors in maintaining competitiveness in the market. As manufacturing technology evolves, understanding the nuances of material properties and their implications on mold design can drive innovation in product development. Ensuring that operatives are well-versed in the latest practices not only improves efficiency but also contributes to producing high-quality components that meet stringent industry standards.

In today's competitive manufacturing landscape, enhancing design accuracy in injection molding is crucial for achieving optimal efficiency and reducing costs. Leveraging simulation tools has become a cornerstone strategy for engineers looking to refine their designs before production. By employing advanced simulation software, designers can create virtual prototypes that mimic real-world conditions, allowing for a thorough analysis of potential issues related to material flow, cooling rates, and part warpage. This iterative process significantly shortens the development cycle and minimizes the risk of costly modifications during later stages of production.

Furthermore, simulation tools empower teams to experiment with various design iterations swiftly. Designers can tweak parameters, such as wall thickness and gate location, and immediately observe the effects on part performance. This capability promotes innovation and allows for the optimization of designs in a fraction of the time traditional methods would require. Ultimately, integrating simulation technologies not only enhances the accuracy of design outcomes but also contributes to the overall quality of molded parts, leading to higher customer satisfaction and a stronger market position.