In today's highly competitive manufacturing landscape, businesses are continually seeking ways to optimize their production processes and enhance their product offerings. One strategy that has gained significant traction is Large Scale Injection Molding, a method that allows for the efficient production of high-quality plastic components at an impressive rate. According to a recent report by Grand View Research, the global injection molding market is expected to reach USD 346.5 billion by 2025, driven by increasing demand from industries such as automotive, consumer goods, and medical devices. The ability to produce large quantities while maintaining precision and consistency makes Large Scale Injection Molding a cornerstone of modern manufacturing. In this blog, we will explore eight essential benefits of this innovative process and how incorporating it into your business strategy can lead to substantial success and growth.

Large scale injection molding presents a multitude of key advantages that can significantly streamline production processes across various industries. One of the primary benefits lies in its ability to produce high volumes of components with exceptional consistency and speed. This efficiency is crucial for businesses that require rapid turnaround times and reliable output, particularly in fields such as packaging and medical technology.

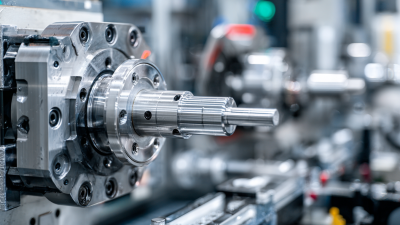

The integration of smart manufacturing technologies with injection molding further enhances its capabilities, enabling advanced automation and precision, which are vital for modern production lines.

Moreover, the transition from traditional manufacturing methods to large scale injection molding facilitates innovation by allowing rapid prototyping and development of complex designs. Recent advancements in materials and manufacturing techniques, including additive manufacturing, complement this process by enabling the creation of intricate components directly from computer models. As companies strive to bridge the gap between research and commercialization, large scale injection molding not only supports efficient manufacturing but also paves the way for new applications and innovations across industries. These factors combined make it an essential component for any business aiming for success in today’s competitive landscape.

Large scale injection molding offers significant cost efficiency advantages that can greatly benefit your business. According to a report by Grand View Research, the global injection molding market is projected to reach $487.8 billion by 2027, driven by increasing demand across various industries such as automotive, consumer goods, and healthcare. By investing in large scale injection molding, companies can leverage economies of scale, significantly reducing production costs per unit. This is particularly beneficial for businesses that require high-volume manufacturing, as the cost savings can be substantial when producing millions of parts.

Moreover, advanced injection molding technologies and materials have been developed to improve production efficiency. Industry data indicates that large scale production can decrease cycle times by up to 30% compared to traditional methods. This reduction not only leads to faster turnaround times but also minimizes labor and energy costs, further enhancing overall profitability. As companies strive to stay competitive, embracing large scale injection molding is a strategic move that can drive down manufacturing expenses while maintaining product quality and consistency.

Large scale injection molding is transforming how businesses maintain product consistency, allowing for high-quality manufacturing at an unprecedented rate. According to a report by Grand View Research, the global injection molding market is projected to reach $331.66 billion by 2025, driven by the need for precision in manufacturing. Utilizing advanced molding techniques can significantly reduce variations in product quality, ensuring that each item produced meets the same rigorous specifications. This consistency not only enhances brand reputation but also fortifies customer trust.

Tips for achieving consistency in your injection molding process include regular calibration of machinery to avoid deviations due to wear and tear. Additionally, implementing rigorous quality control checks at each stage can help catch potential defects early in the process, ultimately reducing waste and production costs. Industry studies suggest that companies that prioritize quality management in their injection molding operations can see an increase in overall efficiency by up to 30%.

Moreover, leveraging simulation software for mold design enables manufacturers to identify potential production issues before they arise, leading to smoother operations and enhanced product uniformity. An estimated 70% of molding defects can be avoided with proper simulation techniques, which ultimately boosts profitability. Business leaders should consider investing in training for their teams on these advanced technologies to maximize the benefits of large-scale injection molding.

In today's fast-paced market, flexibility in design has become a critical factor for businesses aiming to stay ahead of the competition. Large scale injection molding offers a unique advantage by allowing manufacturers to create intricate, customized designs that can be adapted to meet shifting consumer preferences and demands. This manufacturing process supports rapid prototyping and short production runs, enabling companies to test new ideas without committing extensive resources upfront. As a result, businesses can respond swiftly to market trends, ensuring their products remain relevant and engaging to customers.

Moreover, the adaptability of large scale injection molding extends beyond just product design. It facilitates modifications to existing products based on consumer feedback or technological advancements. With the ability to fine-tune molds and materials easily, engineers can implement changes quickly, reducing time-to-market significantly. This agility provides businesses with the opportunity to innovate continuously and maintain a competitive edge in their respective sectors. The robust nature of this molding technique ensures that quality is never compromised, even as designs evolve, making it a valuable asset for any business focused on long-term success.

Large scale injection molding is revolutionizing the manufacturing landscape, significantly enhancing the time-to-market for businesses. In today's fast-paced environment, companies are under constant pressure to deliver high-quality products rapidly. By leveraging large scale injection molding, businesses can produce large quantities of complex parts and components quickly, reducing lead times and ensuring that products reach the market faster than ever before. This capability is especially crucial in industries like automotive and consumer electronics, where innovation cycles are short, and the demand for new products is relentless.

Moreover, large scale injection molding not only accelerates production but also elevates the consistency and quality of the finished products. The advanced technology used in this molding process allows for precise control over the manufacturing parameters, resulting in fewer defects and less waste. As businesses focus on meeting customer expectations while minimizing costs, achieving high-quality production quickly becomes a competitive advantage. In this way, companies that adopt large scale injection molding not only enhance their operational efficiency but also position themselves for sustainable growth in an increasingly competitive market.