The automotive industry is undergoing a transformative phase, largely influenced by advancements in manufacturing technologies such as injection molding. As per a recent report by Smithers Pira, the global automotive plastic parts market is projected to reach over $42 billion by 2025, with injection molding playing a crucial role in this growth. This manufacturing process not only enhances design flexibility but also optimizes material use, contributing to lighter vehicles that improve fuel efficiency. Additionally, a study from the American Society for Testing and Materials (ASTM) highlights that injection molded components can reduce production costs by up to 25% compared to traditional manufacturing methods. As car manufacturers strive to meet stringent environmental regulations and consumer demand for innovative design, the Injection Molding Automotive Industry is poised to revolutionize vehicle aesthetics, performance, and sustainability.

The automotive industry is undergoing a transformative phase, largely influenced by advancements in manufacturing technologies such as injection molding. As per a recent report by Smithers Pira, the global automotive plastic parts market is projected to reach over $42 billion by 2025, with injection molding playing a crucial role in this growth. This manufacturing process not only enhances design flexibility but also optimizes material use, contributing to lighter vehicles that improve fuel efficiency. Additionally, a study from the American Society for Testing and Materials (ASTM) highlights that injection molded components can reduce production costs by up to 25% compared to traditional manufacturing methods. As car manufacturers strive to meet stringent environmental regulations and consumer demand for innovative design, the Injection Molding Automotive Industry is poised to revolutionize vehicle aesthetics, performance, and sustainability.

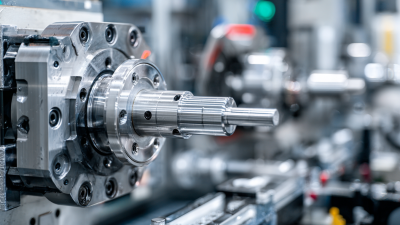

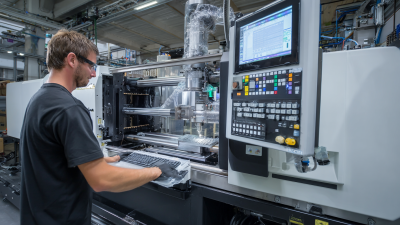

Injection molding has emerged as a pivotal technology in the automotive industry, significantly altering the landscape of vehicle design and manufacturing. This versatile process allows for the high-volume production of complex parts using various materials, primarily plastics. By molding components with intricate shapes and tight tolerances, manufacturers can create lightweight yet durable parts that enhance vehicle performance and efficiency. Furthermore, the rapid production capabilities of injection molding make it an attractive option for meeting the increasing demands of the automotive market.

**Tips:** When considering injection molding for automotive applications, pay attention to material selection. The properties of the chosen plastic can affect not only the strength and durability of the parts but also their resistance to heat and chemicals. Collaborating with experienced design engineers can also ensure that parts are optimized for both functionality and manufacturability.

Integration of injection-molded components allows automakers to streamline assembly processes and reduce overall vehicle weight, ultimately leading to better fuel efficiency and lower emissions. As innovative materials and technologies are developed, the potential applications of injection molding in automotive design will only continue to expand, paving the way for advanced vehicle designs that meet modern consumer needs.

**Tips:** Always prototype new designs to test the fit and function of injection-molded parts before full-scale production. This step can reveal potential issues early on and save time and resources in the long run. Regularly revisiting design specifications is also crucial to adapt to new materials and manufacturing techniques.

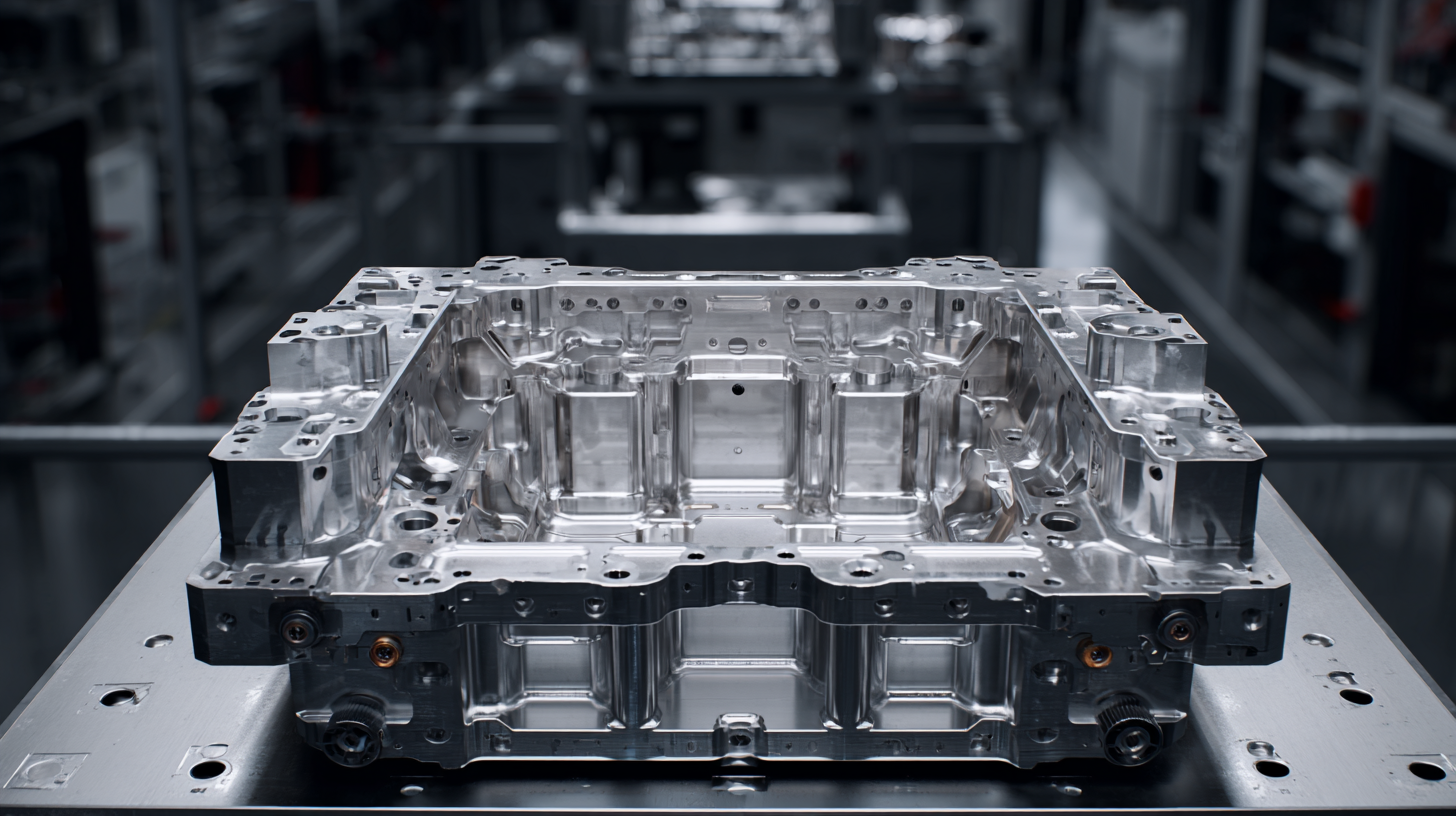

Injection molding has emerged as a transformative force in the automotive industry, particularly in enhancing vehicle efficiency. This manufacturing process allows for the precise production of complex shapes and lightweight components, which are essential for modern vehicle design. By utilizing materials such as thermoplastics and composites, manufacturers can create parts that are not only lightweight but also robust, helping to reduce the overall weight of vehicles. This weight reduction plays a crucial role in improving fuel efficiency and lowering emissions, aligning with global demands for more sustainable transportation solutions.

Furthermore, injection molding facilitates a quicker production time and reduces material waste, contributing to both economic and environmental benefits. The ability to produce intricate designs means that less assembly is required, streamlining the manufacturing process. As automakers increasingly focus on efficiency, the innovations brought by injection molding support the trend toward electric and hybrid vehicles, which rely heavily on lightweight materials for optimal performance. In this way, injection molding is not just enhancing vehicle designs; it is also paving the way for a more efficient and sustainable future in the automotive industry.

Injection molding has emerged as a transformative technology in the automotive industry, significantly shaping the design and functionality of modern vehicles. This manufacturing process allows for the creation of complex geometries with high precision and minimal waste, which is increasingly vital in an era focused on sustainability and efficiency. By using advanced materials, such as lightweight composites and engineering plastics, manufacturers are now able to produce components that not only reduce the overall weight of vehicles but also enhance fuel efficiency and performance.

One of the most innovative applications of injection molding in contemporary vehicle design can be seen in the production of interior cabin elements, such as dashboards, door panels, and consoles. These components can be engineered to include diverse textures and finishes, providing aesthetic appeal while also offering durability. Furthermore, the integration of electronic systems, like touch controls and infotainment interfaces, into molded parts illustrates how this technique can streamline production, reduce assembly time, and lead to more cohesive designs. The evolution of injection molding is not just about improving processes but is also about reimagining what is possible in vehicle design, ultimately leading to smarter, more efficient automobiles.

In the modern automotive industry, the choice of manufacturing processes can significantly influence vehicle design and efficiency. Traditional manufacturing methods often involve techniques like stamping and welding, which can be time-consuming and require substantial material expenditure. In contrast, injection molding allows for the creation of complex shapes with high precision while minimizing waste. This not only speeds up production times but also enables designers to think outside the box, making innovative and ergonomic designs more feasible.

**Tip:** When considering injection molding for vehicle components, collaborate closely with engineers early in the design process to optimize part geometry for manufacturability, ensuring both aesthetic and functional needs are met without compromising efficiency.

The comparative advantages of injection molding also lie in its material versatility. Traditional manufacturing is often limited to specific metals and materials, whereas injection molding can accommodate a range of plastics and composites, some of which are lightweight yet highly durable. This flexibility facilitates advancements in fuel efficiency and contributes to the overall sustainability of vehicle production.

**Tip:** Utilize computer-aided design (CAD) tools to simulate and validate your injection molded parts, which can lead to cost savings and fewer iterations in development, ultimately achieving a more efficient production timeline.

| Aspect | Traditional Manufacturing | Injection Molding |

|---|---|---|

| Production Time | 4-6 weeks | 1-3 weeks |

| Cost per Unit | $50 - $100 | $10 - $30 |

| Material Waste | 20% | 1-5% |

| Design Flexibility | Limited | High |

| Production Volume | Low to Medium | High |

| Weight of Components | Heavier | Lighter |

| Environmental Impact | Higher | Lower |

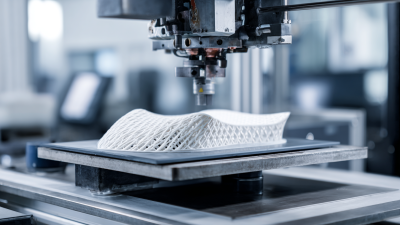

The automotive landscape is undergoing a significant transformation, particularly with the rise of electric and autonomous vehicles. One of the key contributors to this evolution is the adoption of injection molding techniques that utilize continuous fiber-reinforced thermoplastics. This innovative approach not only enhances vehicle design but also improves overall efficiency. By enabling the production of lightweight yet robust components, manufacturers can create vehicles that consume less energy and offer better performance.

As the market for continuous fiber-reinforced thermoplastics is projected to grow from approximately $103.74 million in 2024 to $146.75 million by 2032, the impact of injection molding on future automotive designs cannot be overstated. With an anticipated growth rate of 4.5%, this trend highlights the increasing demand for materials that can meet the stringent requirements of electric and autonomous vehicles. These vehicles, which rely heavily on advanced materials for performance and sustainability, will benefit immensely from the design flexibility and efficiency offered by injection molding processes, ultimately shaping the future of the automotive industry.