Injection Molding Automotive Parts is a critical process in the automotive industry. This method allows for high-volume production of complex parts with precision. It combines material efficiency with design flexibility.

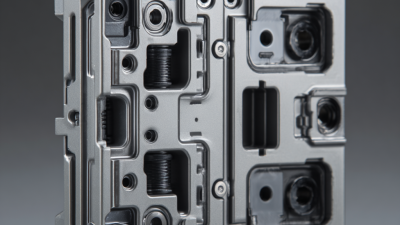

In automotive manufacturing, durability and reliability are essential. Injection molding addresses these needs by providing strong, lightweight components. For instance, dashboard elements or engine covers benefit from this technique. However, challenges exist in ensuring consistent quality. Minor variations can affect part performance and aesthetic appeal.

Understanding the injection molding process is vital for engineers. They must consider factors like material selection and cooling times. Mistakes in these areas can lead to wasted time and resources. Continuous improvement is necessary to refine techniques. This approach leads to better products and increased efficiency in production lines.

Injection molding plays a critical role in automotive parts production. It allows manufacturers to create complex shapes efficiently. This method is not just fast; it can also minimize waste. In fact, a recent industry report states that injection molding can reduce material waste by up to 30%. This is significant for cost management and environmental responsibility.

Understanding the basics of injection molding is essential for automotive applications. The process involves melting plastic and injecting it into a mold. This can lead to precision parts that meet exact specifications. However, it's crucial to note that mold design can be a tricky endeavor. A poorly designed mold can lead to defects, impacting quality. According to some studies, around 20% of manufacturing defects in the automotive industry stem from molding challenges.

The choice of materials also influences the outcome. Different plastics offer various characteristics, such as durability and weight. Selecting the right material is not always straightforward. For instance, while lighter materials can improve fuel efficiency, they may compromise safety. Balancing these factors requires careful thought and testing. Thus, while injection molding is a powerful tool, it brings its own set of complexities that require ongoing evaluation.

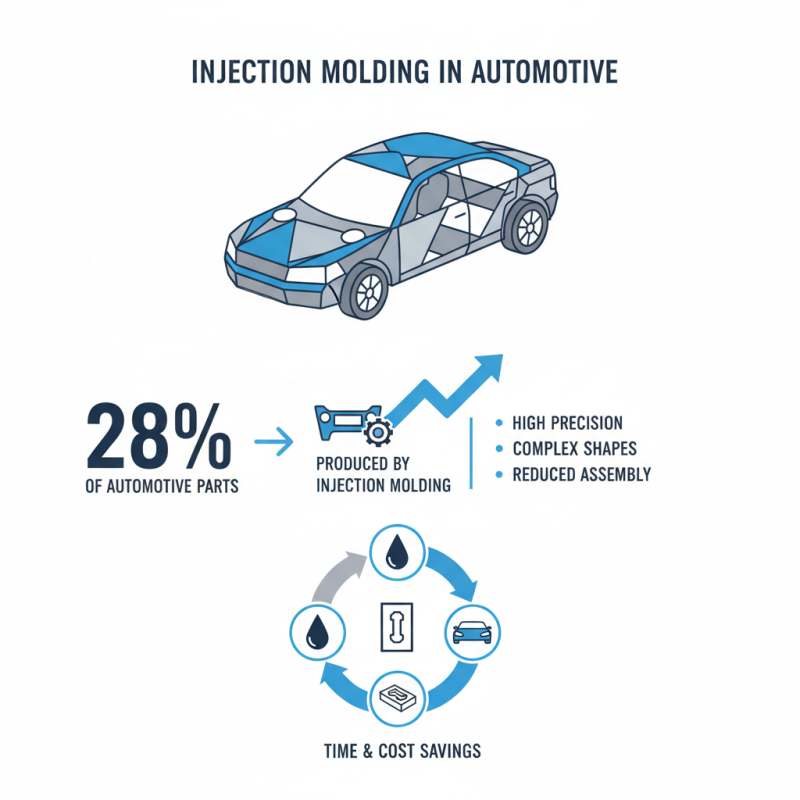

Injection molding is increasingly becoming a vital technology in automotive parts manufacturing. Reports indicate that around 28% of automotive parts are now produced through this method. The process allows for high precision and efficiency. It can produce complex shapes that can be tailored to specific needs. This reduces the need for secondary operations, saving both time and costs.

One major advantage of injection molding is its ability to use a variety of materials. From thermoplastics to elastomers, manufacturers have many options. This versatility allows for enhanced performance and durability. For instance, studies show that components made with injection-molded plastics can weigh up to 50% less than their metal counterparts. This contributes to improved fuel efficiency in vehicles.

However, there are challenges. The initial costs for tooling can be high, and setup times may be lengthy. In some cases, companies may overestimate demand, leading to excess production. These factors require careful planning and market analysis. Finding the right balance between speed and quality is often difficult. Therefore, some manufacturers may struggle initially with the transition to injection molding.

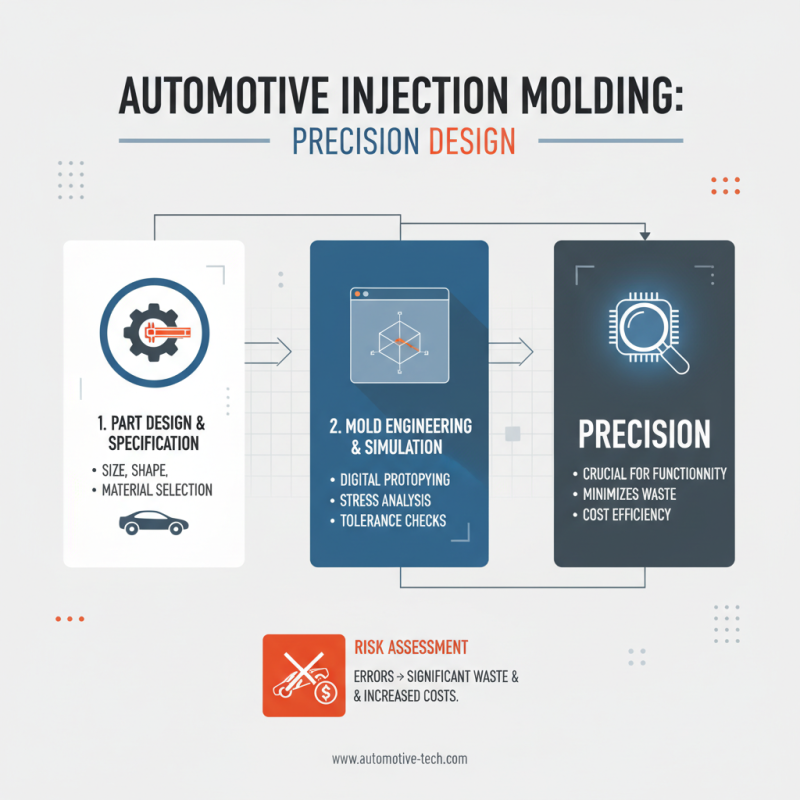

Injection molding is a popular method for producing automotive parts. The process begins with designing a mold that matches the required specifications. Engineers need to consider the part's size, shape, and material. Precision is crucial here. Any errors can lead to significant waste and increased costs.

After designing the mold, the next step involves selecting the right material. Common choices include thermoplastics and thermosetting plastics. Each material has unique properties. Choosing the wrong one can affect the part's durability and performance. Keep in mind the environmental impact of the materials as well.

Once the mold and material are in place, the injection process begins. The plastic is heated and injected into the mold under pressure. It cools down and solidifies, taking the mold's shape. This requires careful control of temperature and pressure. It's critical to monitor these factors closely. Minor adjustments can make a significant difference.

**Tip:** Always prototype before full production. This can help identify design flaws early on. It saves time and resources.

After the parts are formed, they need to be ejected from the mold. This step can sometimes damage the component if not handled correctly. Reviewing the ejection mechanism is necessary. A poorly designed ejector can lead to defects in the final product.

**Tip:** Test your molds regularly. This ensures they are still functioning properly. Consistent maintenance can prevent costly downtime.

Selecting the right materials for injection molding in the automotive industry is crucial. These materials affect the durability, safety, and overall performance of automotive parts. According to a recent market report, over 40% of automotive components are now made from plastics, with injection molding being a preferred method. The right choice can enhance vehicle aesthetics and reduce weight, contributing to energy efficiency.

There are several options available, including thermoplastics, thermosetting plastics, and elastomers. Polypropylene is commonly used for interior parts due to its strength and flexibility. A study shows that using lightweight materials can lead to a 10% decrease in fuel consumption, which is a substantial benefit in the industry.

Tip: Consider material additives that can improve properties like UV resistance or impact strength. This can elevate product performance but may increase costs. Additionally, keep in mind the environmental aspects. Some materials may have a higher carbon footprint during production. Striving for a balance between cost-effectiveness and sustainability is essential.

In the end, the complexities of material choices can lead to challenges. Manufacturers must reflect on how sourcing decisions can impact overall production timelines. The quality of materials can vary, affecting batch consistency, which is vital in automotive applications. Continuous evaluation of material performance is key to success.

Quality control is crucial in automotive injection molding. According to the Plastics Industry Association, defects can lead to significant financial losses, with a single bad part costing over $5,000 on average. Therefore, manufacturers focus on stringent quality measures throughout the production cycle.

One key measure is the use of statistical process control (SPC). This involves monitoring production parameters in real-time. By identifying variations, manufacturers can quickly address potential issues. Despite its importance, many still struggle with inconsistent data collection. A recent study noted that 30% of companies lack effective monitoring systems, impacting their quality assurance processes.

Another vital aspect is the selection of raw materials. Quality materials lead to better finished products. Some studies indicate that using recycled plastics can compromise part integrity. The Society of Plastics Engineers estimates that 20% of automotive parts fail to meet safety standards due to poor material choices. Continuous assessment and testing can mitigate these risks. Yet, many manufacturers do not prioritize thorough pre-production testing, leaving room for improvement.

| Process Step | Description | Quality Control Measure | Frequency |

|---|---|---|---|

| Material Selection | Choose appropriate polymers for specific automotive applications. | Material certification and testing for compatibility. | Every batch |

| Mold Design | Design molds to accommodate precise specifications and tolerances. | CAD validation and simulation of mold flow. | Before production |

| Injection Process | Injecting molten material into the mold under controlled conditions. | Real-time monitoring of temperature and pressure. | Continuously during production |

| Cooling Phase | Allowing components to cool and solidify in the mold. | Temperature checks to ensure proper cooling rate. | Each cycle |

| Final Inspection | Inspect finished parts for defects and dimensional accuracy. | Visual inspection and dimensional measurement. | Every 100 parts |