Injection Molding Plastic for Marine Application has steadily gained traction in the maritime industry due to its excellent durability and resistance to harsh environmental conditions. According to a report by the Freedonia Group, the demand for engineered plastics in marine applications is projected to grow by 4.2% annually, reflecting the industry's shift towards more resilient materials.

Injection Molding Plastic for Marine Application has steadily gained traction in the maritime industry due to its excellent durability and resistance to harsh environmental conditions. According to a report by the Freedonia Group, the demand for engineered plastics in marine applications is projected to grow by 4.2% annually, reflecting the industry's shift towards more resilient materials.

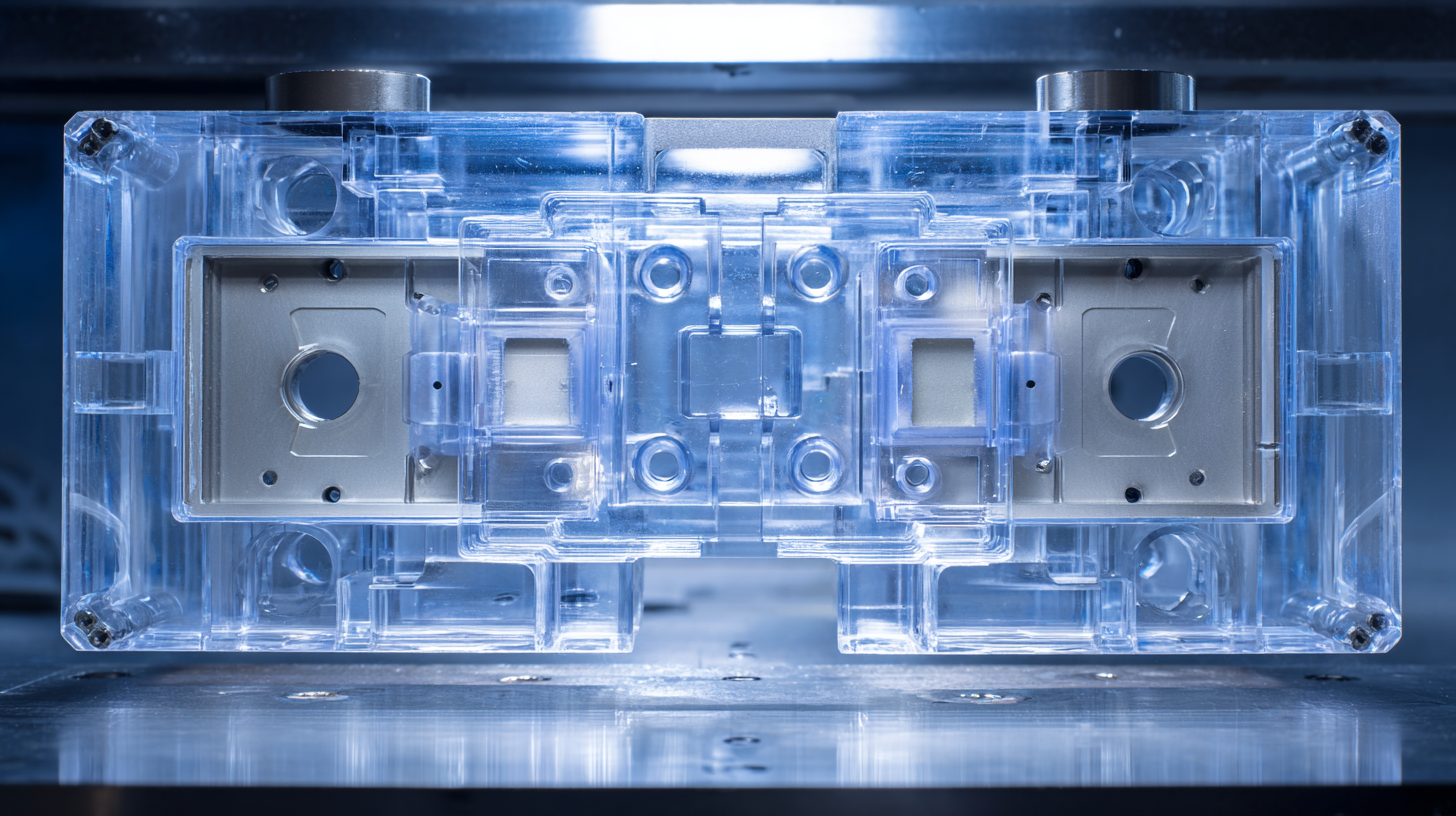

Injection molding processes not only enhance the design flexibility of marine components but also reduce production waste and costs, making it a highly efficient choice. Furthermore, the American Society for Testing and Materials (ASTM) highlights that plastics produced via injection molding can outperform traditional materials in marine environments, offering superior resistance to UV exposure, corrosion, and impact.

As the marine sector continues to seek innovative solutions to enhance durability and sustainability, the role of injection molding plastics becomes increasingly vital.

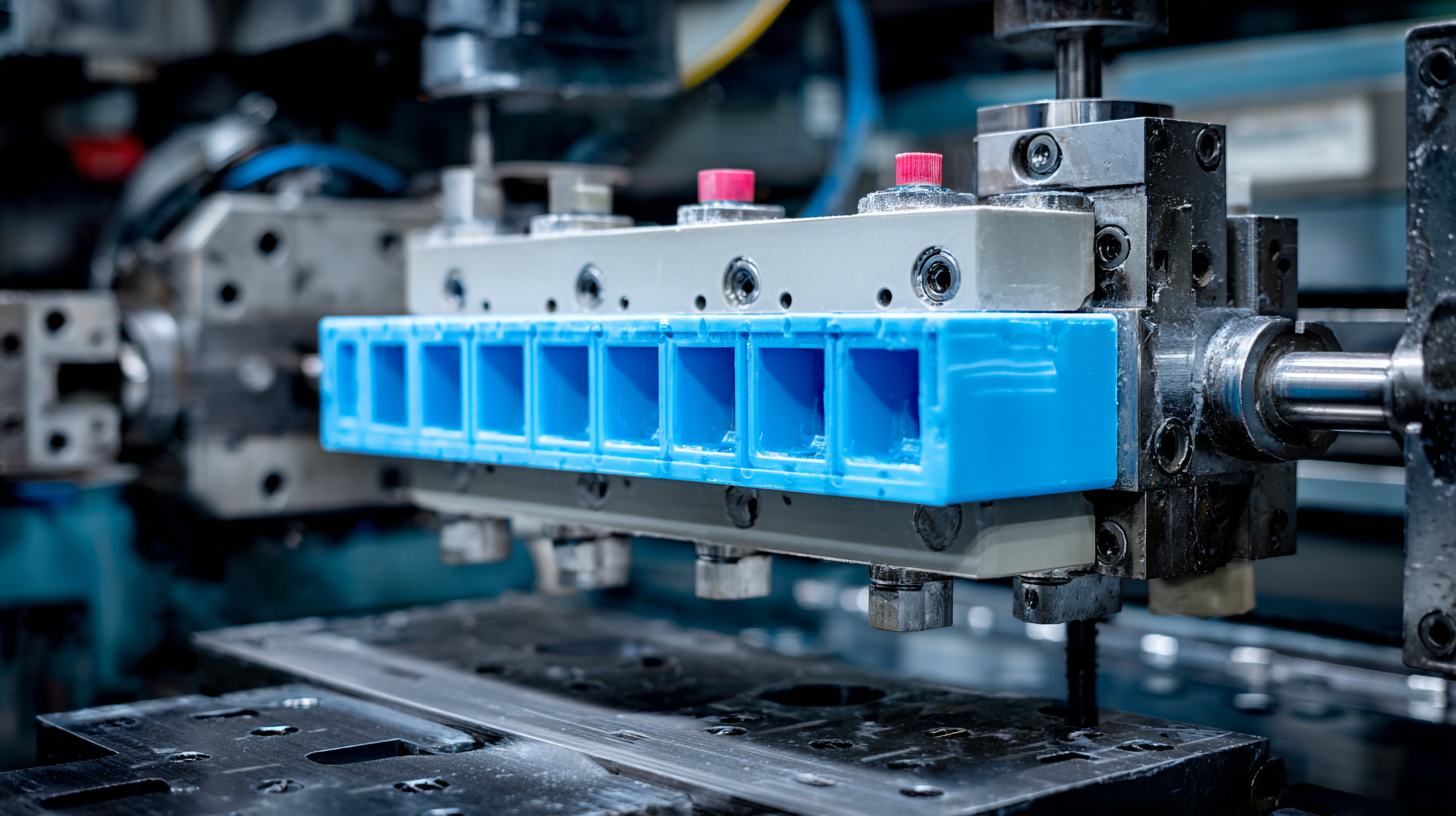

Injection molding plastic has become an essential component in the marine industry, especially when it comes to enhancing the durability and longevity of marine equipment. One of the key advantages of using injected molded plastics is their resistance to harsh environmental conditions, including saltwater exposure, UV radiation, and extreme temperatures. This resistance significantly reduces the wear and tear that traditional materials face, ensuring that marine equipment remains functional and reliable over extended periods.

Moreover, injection molding allows for the production of complex shapes and designs that can be tailored to the specific needs of marine applications. This customization not only contributes to improved performance but also enhances the operability of various marine components, from hulls to interior fittings. The lightweight nature of plastic, combined with its ability to withstand corrosive elements, further minimizes maintenance requirements and prolongs the lifecycle of marine equipment, ultimately providing cost savings for boat owners and operators. This synergy of durability and performance positions injection molded plastic as a superior choice for enhancing the longevity of marine applications.

Injection molding plastics have become increasingly important in enhancing marine durability due to their unique properties that cater specifically to the harsh marine environment. One key property of these plastics is their exceptional resistance to moisture and seawater, which significantly reduces the risk of corrosion compared to traditional materials like metals and wood. According to a report by the Plastics Industry Association, the use of polymer materials in marine applications can lead to a reduction in maintenance costs by up to 50%, highlighting both the economic and practical benefits of these advanced plastics.

Another significant property of injection-molded plastics is their lightweight nature, which contributes to improved fuel efficiency in marine vessels. A study conducted by the American Boat Builders and Repairers Association found that using lightweight composites can lead to a fuel savings of approximately 10-15%, depending on the design and application of the marine craft. Additionally, injection molding allows for intricate designs and customizations, enabling manufacturers to create components that meet specific operational demands while maintaining structural integrity in the face of dynamic marine conditions. This combination of durability, efficiency, and design flexibility makes injection-molded plastics an ideal choice for modern marine applications.

| Property | Benefit | Description |

|---|---|---|

| Corrosion Resistance | Extended Lifespan | Injection molding plastics repel water and resist saltwater corrosion, leading to longer-lasting marine components. |

| UV Stability | Reduced Degradation | Plastics with UV stabilizers prevent color fading and physical degradation due to sunlight exposure. |

| Lightweight | Improved Efficiency | Reduced weight helps in enhancing fuel efficiency and performance of marine vessels. |

| Thermal Stability | Performance in Extreme Conditions | High thermal resistance ensures materials maintain integrity under varying temperature conditions. |

| Chemical Resistance | Safety and Reliability | Ability to withstand exposure to harsh chemicals found in marine environments without deteriorating. |

The use of injection molding plastic offers significant advantages in marine product design, particularly in terms of cost-effectiveness. This manufacturing process allows for high-volume production with minimal waste, making it economical for companies looking to create high-quality marine products. The precision of injection molding ensures that each piece is made to exact specifications, reducing the need for costly adjustments or reworks later in the production cycle. As a result, businesses can benefit from lower overall costs while producing durable and reliable components for marine applications.

**Tips:** When considering injection molding for marine products, it's essential to choose high-grade plastics specifically designed for marine environments. These materials are resistant to moisture, UV rays, and various chemicals, ensuring long-lasting performance. Furthermore, efficient design can lead to reduced material costs; optimizing the shape and structure of parts can minimize the amount of plastic used while maintaining strength.

Additionally, investing in advanced molds can significantly enhance productivity. While the upfront cost may be higher, durable molds lead to less wear and tear over time. This investment pays off by improving manufacturing efficiency and product quality, ultimately contributing to the cost-effectiveness of the entire marine product development process.

Injection molding plastics offer significant sustainability benefits, particularly in marine industries where durability and environmental impact are crucial considerations. One of the primary advantages is the efficient use of materials during production. Injection molding allows for precise control over the quantity of plastic used, minimizing waste during manufacturing processes. This efficiency not only reduces material costs but also lessens the environmental footprint associated with excess plastic production.

Injection molding plastics offer significant sustainability benefits, particularly in marine industries where durability and environmental impact are crucial considerations. One of the primary advantages is the efficient use of materials during production. Injection molding allows for precise control over the quantity of plastic used, minimizing waste during manufacturing processes. This efficiency not only reduces material costs but also lessens the environmental footprint associated with excess plastic production.

Moreover, injection molded plastics can be designed with recyclable properties, encouraging a circular economy within marine applications. By using biodegradable or recyclable resins, manufacturers can create products that do not endanger marine ecosystems after their lifecycle. This shift towards sustainability is essential for preserving marine environments, as traditional materials often lead to pollution and hazardous waste. As the marine industry increasingly prioritizes eco-friendly practices, the adoption of injection molding plastics represents a progressive step towards reducing ecological harm while enhancing the durability of marine components.

Innovative injection molding techniques are becoming increasingly essential in enhancing marine durability by utilizing advanced materials designed to withstand harsh marine environments. Recent developments highlight the integration of glass-reinforced polymers that not only improve structural rigidity but also enhance the aesthetic appeal and eco-friendliness of marine products. These materials are particularly relevant for applications such as surfboard fins, where performance and sustainability are paramount. By adopting these innovative solutions, manufacturers can create durable marine components that meet modern ecological standards.

Innovative injection molding techniques are becoming increasingly essential in enhancing marine durability by utilizing advanced materials designed to withstand harsh marine environments. Recent developments highlight the integration of glass-reinforced polymers that not only improve structural rigidity but also enhance the aesthetic appeal and eco-friendliness of marine products. These materials are particularly relevant for applications such as surfboard fins, where performance and sustainability are paramount. By adopting these innovative solutions, manufacturers can create durable marine components that meet modern ecological standards.

Additionally, the emergence of biodegradable molding materials signifies a significant shift towards sustainability in the marine industry. Notably, recent advancements in marine biodegradable cellulose fiber demonstrate the potential for developing products that minimize environmental impact without compromising durability. As the focus on sustainable practices grows, such innovations not only enhance the resilience of marine structures but also promote a cleaner marine ecosystem. This synergy between advanced injection molding techniques and sustainable material development is crucial for the future of marine applications, fostering a balance between performance and environmental responsibility.