Injection molding is a fascinating yet complex process. For beginners, mastering this technique can appear daunting. It involves precision, attention to detail, and a grasp of essential machinery. By understanding the basics, you can create functional and aesthetically pleasing parts.

Many newcomers struggle with common pitfalls. They often overlook crucial settings like temperature and pressure. This can lead to defects in the final product. It's vital to experiment and refine your approach. Even minor adjustments can yield significant improvements. Learning from mistakes is part of the journey.

Emphasizing practical knowledge is key. Observing experienced molders can offer insights that textbooks may miss. The world of injection molding is nuanced. Each project presents unique challenges worth exploring. Embrace the learning curve, and don’t rush the process.

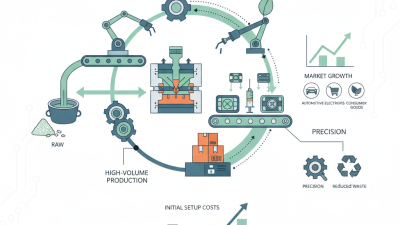

Injection molding is a critical manufacturing process. It forms complex shapes using molten plastic. Understanding this technology can transform production efficiency. It accounts for 30% of plastic parts manufacturing globally. This number highlights its importance in various industries.

Beginners often face challenges when starting with injection molding. The process requires precision in temperature control and material selection. For example, maintaining the right temperature is essential. Too hot or too cold can lead to defects. Reports suggest that 15% of beginners struggle with these fundamentals. Overcoming these obstacles is key to mastering this technique.

The cycle time is vital in production efficiency. Typical cycles range from 15 seconds to several minutes depending on part complexity. Improving this metric can significantly impact costs. Yet, many beginners overlook the impact of cooling times. Around 40% of production delays stem from improper cooling procedures. Innovating in this area can lead to faster outputs.

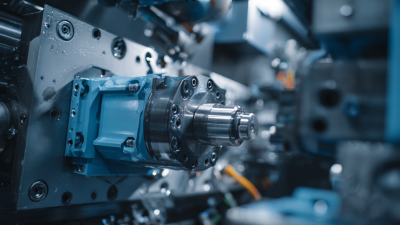

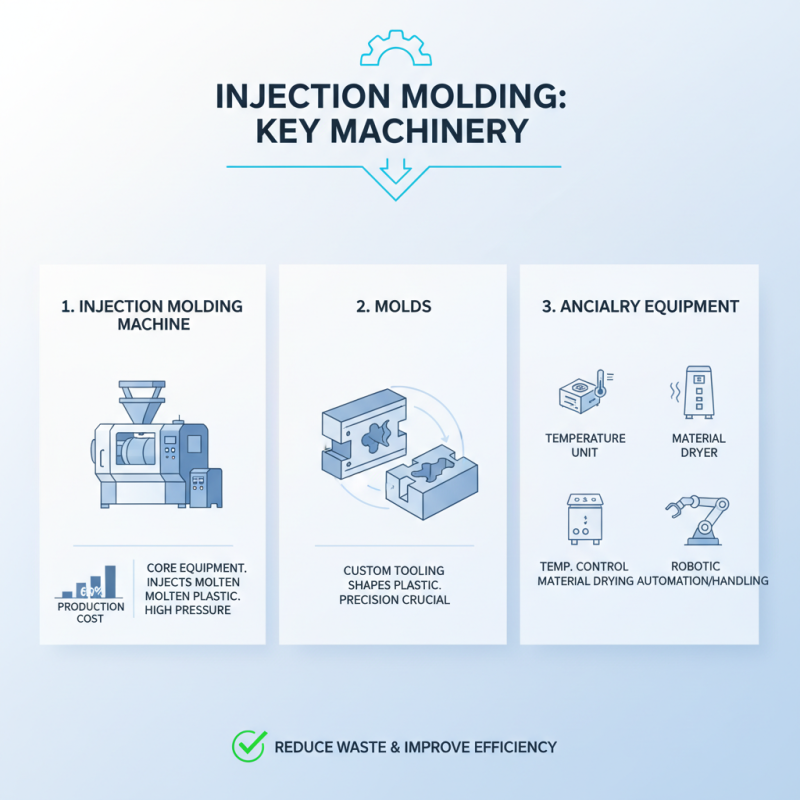

Injection molding is a complex process that requires specific equipment to ensure success. Understanding the key machinery involved is crucial for beginners. A high-quality injection molding machine is essential. These machines provide the necessary pressure to inject molten plastic into the molds. Reports indicate that over 60% of production costs come from machinery and setup. Investing in reliable equipment can improve efficiency and reduce waste.

Molds are another critical component. The quality of the mold directly impacts the final product. There are many types of molds, such as single-cavity and multi-cavity designs, each with its advantages. Beginners should choose molds that match their production needs. Additionally, maintaining the molds is vital. Minor defects can lead to significant product defects. Regular inspection can prevent costly mistakes.

Tips for newcomers include conducting proper training. Familiarize yourself with the equipment manual. Understanding every function can prevent errors. Monitor temperature and pressure closely during the injection process. Small variations can lead to large discrepancies in the final product. Also, engage in regular maintenance. This ensures that your equipment remains in optimal condition. Overall, being mindful of these aspects can significantly enhance your injection molding experience.

Setting up an injection mold requires careful planning and attention to detail. Begin by selecting the right materials for your mold. A common choice is aluminum for its affordability and ease of machining. However, steel is often preferred for higher durability. Research indicates that over 50% of production errors stem from mold design flaws. So, getting the design right at the start is crucial.

Once you've selected your materials, the next step is to design the mold itself. Utilize CAD software to create precise designs. This software can help identify potential issues before production begins. It's vital to consider aspects like draft angles and cooling channels. Practical adjustments such as these can significantly reduce cycle times and enhance product quality.

Tip: Pay attention to venting. Improper venting can lead to defects in molded parts. Ensure there are enough venting pathways to allow trapped air to escape. Moreover, consider the temperature control system during the injection process. Maintaining consistent temperatures can prevent warping and improve the final product.

After setting up the mold and running initial tests, closely monitor the results. Analyze the output and adjust settings as needed. Don't be afraid to revisit your design if issues arise. This iterative process is essential for mastering injection molding. Remember, making mistakes is part of learning.

Injection molding can present several challenges for beginners. One common issue is controlling temperature. If the material overheats, it can degrade. This leads to poor quality parts. To mitigate this, monitor the temperature closely. Use thermocouples and adjust the heater settings as needed.

Another challenge is achieving consistent pressure during the molding process. Inconsistent pressure can cause defects like flash or incomplete filling. To address this, ensure your mold is well-designed. Pay attention to the mold ventilation, which can impact pressure levels. Regularly inspect the mold for wear or buildup, as this can affect performance.

Additionally, not every attempt will yield perfect results. It's essential to reflect on mistakes. Each failure can provide valuable lessons. Analyzing what went wrong can help improve future runs. Embracing imperfection is part of mastering injection molding.

Injection molding is a complex process that can be optimized for better production efficiency. One critical area is material selection. Choosing the right raw materials can significantly affect the flow and cooling times. Not all plastics perform well under all conditions. Testing different materials can yield surprising results. Sometimes, a less expensive alternative performs just as well.

Machine settings also play a vital role. Adjusting temperature, pressure, and cycle time affects product quality and production speed. It's common to find that settings optimized for one part result in defects. This inconsistency can lead to wasted time and resources. Regularly reviewing machine parameters can help identify areas for improvement.

Finally, maintaining clean molds and equipment is essential. Even small debris can cause defects. Routine cleaning might seem tedious, but neglecting it can lead to greater issues down the line. Reflection on production processes can enhance efficiency over time. Each step has room for refinement, no matter how experienced you are.

| Tip | Description | Benefits |

|---|---|---|

| Understand the Material | Familiarize yourself with the properties of various plastics used in injection molding. | Improves final product quality and reduces waste. |

| Optimize Mold Design | Focus on designing molds that facilitate easy flow and cooling of the material. | Increases production speed and reduces defects. |

| Control Temperature | Maintain optimal temperatures for both the material and the mold. | Enhances material flow and part dimensions accuracy. |

| Regular Maintenance | Keep machinery and molds properly maintained to prevent breakdowns. | Increases machine lifespan and minimizes downtime. |

| Test and Iterate | Run trial batches and adjust settings based on results. | Fine-tunes the process leading to improved final products. |