The automotive industry has seen a transformative shift towards innovative designs, especially in the realm of Injection Molding Automotive Parts. As per the latest industry report by MarketsandMarkets, the global injection molding market is projected to reach $488.2 billion by 2025, driven largely by the increasing demand for lightweight materials in automotive applications. This growth underscores the significance of injection molding as a key manufacturing process that not only enhances product performance but also improves cost efficiency. China has emerged as a leader in this sector, boasting advanced manufacturing capabilities that allow it to produce high-quality automotive components for global markets. In this blog, we will delve into case studies that highlight these world-class designs, showcasing the pride of Chinese innovation in the automotive landscape and its commitment to exporting top-notch Injection Molding Automotive Parts worldwide.

Innovative materials are fundamentally transforming the landscape of injection molding in the automotive industry. The shift towards lightweight and high-performance materials, such as advanced thermoplastics and composites, is allowing manufacturers to create automotive parts that not only reduce weight but also enhance durability and sustainability. According to a report by Smithers Pira, the global market for automotive plastics is expected to reach $22 billion by 2025, driven by the increasing demand for fuel-efficient vehicles and stringent emissions regulations.

Moreover, the adoption of bio-based and recycled materials in injection molding processes is gaining traction. A study by MarketsandMarkets predicts that the bio-based plastics market in automotive applications will grow at a compound annual growth rate (CAGR) of 14.5% from 2022 to 2027. This trend reflects a broader commitment within the industry to reduce reliance on fossil fuels and improve the environmental footprint of vehicle production. Consequently, the integration of innovative materials in injection molding not only advances the functionality and aesthetics of automotive components but also aligns with the industry's sustainability goals.

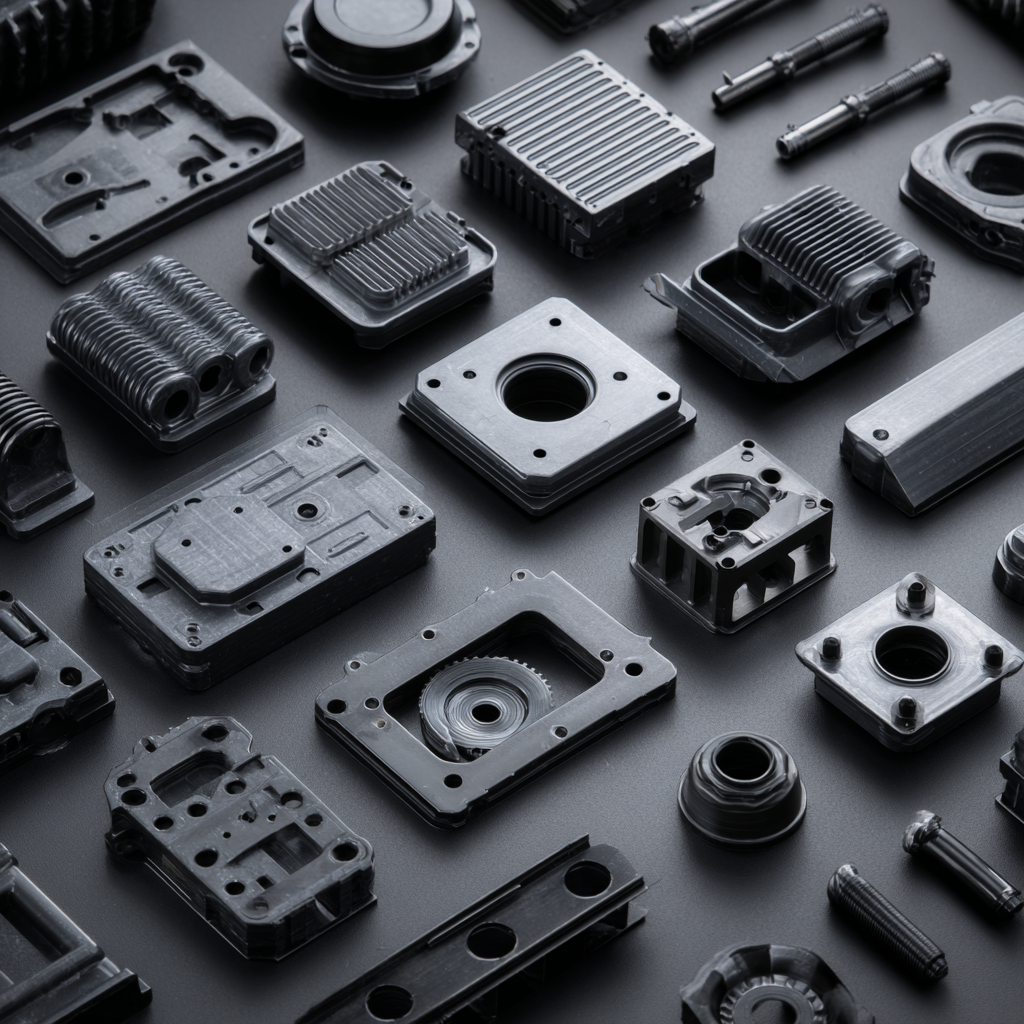

Emerging technologies are revolutionizing the landscape of injection molding in the automotive industry, enhancing production efficiency and product quality. One of the most significant advancements is the incorporation of 3D printing techniques within the injection molding process. This integration allows for the rapid prototyping of complex designs, drastically reducing lead times and enabling manufacturers to iterate quickly based on real-time feedback. As automotive design becomes increasingly intricate, the synergy between 3D printing and injection molding proves invaluable in delivering innovative solutions.

Moreover, advancements in materials science are also shaping the future of injection molding. The development of new polymers offers stronger, lighter, and more sustainable options compared to traditional materials. These next-generation materials not only cater to the need for durability and performance but also align with the industry's push towards sustainability. Techniques such as biodegradable plastics and recycled content are gaining traction, reflecting a growing commitment to environmental responsibility. As these technologies continue to evolve, they will undoubtedly play a crucial role in redefining the standards of manufacturing in the automotive sector.

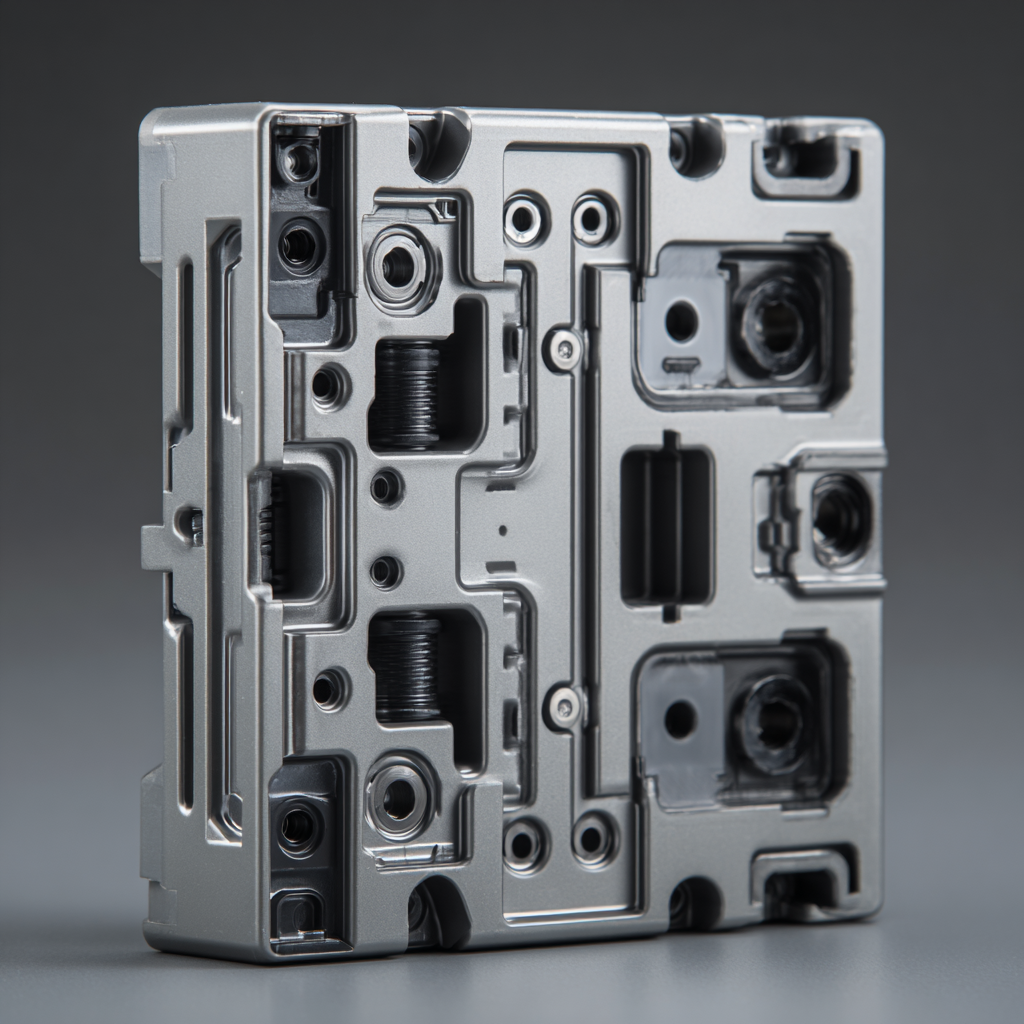

Innovative designs in the automotive industry have transformed the production and functionality of injection-molded parts. Case studies reveal how companies are successfully implementing these designs to enhance vehicle performance while minimizing costs. For instance, one notable case involved a major automotive manufacturer that integrated lightweight materials into their injection-molded components. This shift not only improved fuel efficiency but also boosted the overall performance of their vehicles.

Tips for successful implementation of innovative designs begin with a thorough understanding of material properties. Selecting the right materials for injection molding can lead to significant advancements in durability and weight reduction. Furthermore, collaborating closely with design engineers and suppliers ensures that design prototypes are optimized before full-scale production begins. This can help avoid costly revisions later in the manufacturing process.

Another key aspect is to embrace advanced technologies such as 3D printing for rapid prototyping. This approach allows manufacturers to test multiple design iterations quickly, gaining insights that inform final designs effectively. Involving cross-functional teams throughout this process can foster a culture of innovation, leading to even better solutions in future projects.

The automotive industry is undergoing a significant transformation, with sustainability emerging as a focal point for innovation, especially in injection molding. According to a recent report by Grand View Research, the global automotive injection molding market is expected to reach USD 56.5 billion by 2025, growing at a CAGR of 4.8% from 2019. This growth is driven by the increasing demand for lightweight and eco-friendly components that can help reduce vehicle emissions and enhance fuel efficiency.

As we move toward 2025, several sustainability trends are shaping the future of automotive injection molding. One notable trend is the rising use of bio-based polymers and recycled materials in manufacturing processes. The American Chemistry Council reports that switching to recycled plastics could save up to 15 million metric tons of CO2 emissions per year. Additionally, companies are investing in energy-efficient molding technologies that significantly lower energy consumption during production. This commitment not only reduces operational costs but also meets the growing consumer demand for sustainable automotive solutions in an increasingly eco-conscious market.

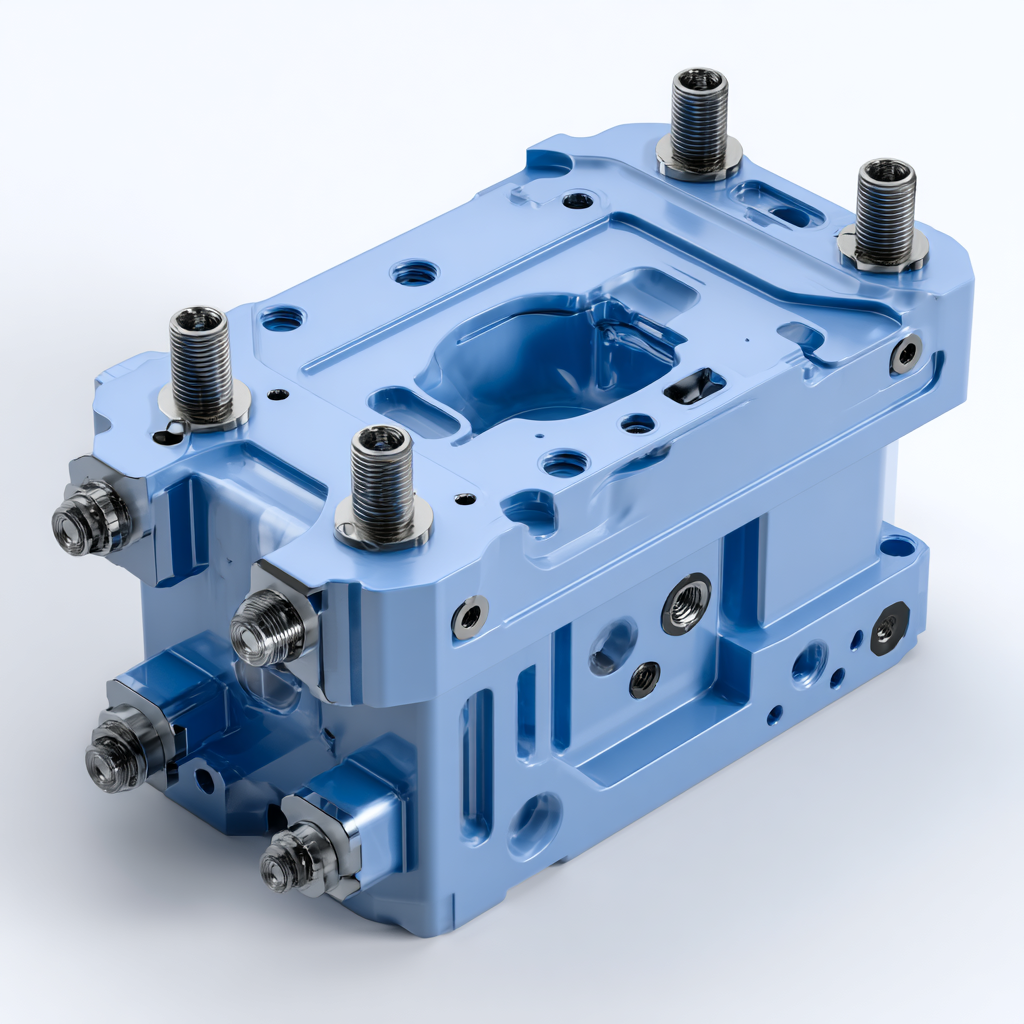

The automotive industry continually seeks innovative solutions to enhance performance while reducing costs, making injection molding a critical technology in this transformation. However, there are several key challenges that manufacturers face in automotive injection molding advancements. One significant challenge is material selection; with a growing demand for lightweight yet resilient components, finding the right materials that meet both strength and weight criteria can be complex. Engineers must navigate various polymers and composites to ensure they meet the rigorous standards required by the automotive sector.

Another challenge involves precision and repeatability in the molding process. As automotive designs become more intricate, the need for precise dimensions and high-quality surface finishes becomes paramount. Addressing this issue often involves investing in advanced machinery and implementing rigorous quality control measures. Companies are increasingly turning to simulation software to predict potential issues in the molding process, allowing for real-time adjustments that can save time and resources. By overcoming these challenges, automotive manufacturers can not only enhance product performance but also achieve greater sustainability in their operations, setting a new standard for the industry.