In the rapidly evolving landscape of modern manufacturing, the significance of Injection Molding Part Design cannot be overstated. With the global injection molding market projected to reach approximately $300 billion by 2025, according to a report by Grand View Research, manufacturers are increasingly seeking innovative techniques to enhance efficiency and reduce costs.

As production demands rise, the integration of advanced technologies—such as 3D printing, computer-aided design (CAD), and simulation software—has become essential in streamlining the design process. These innovations not only improve product quality but also shorten the time-to-market, a critical factor in today's competitive environment.

By leveraging data-driven insights and embracing best practices, companies can optimize their injection molding strategies, ensuring they remain at the forefront of industry advancements while addressing the challenges posed by design complexity and material constraints.

As production demands rise, the integration of advanced technologies—such as 3D printing, computer-aided design (CAD), and simulation software—has become essential in streamlining the design process. These innovations not only improve product quality but also shorten the time-to-market, a critical factor in today's competitive environment.

By leveraging data-driven insights and embracing best practices, companies can optimize their injection molding strategies, ensuring they remain at the forefront of industry advancements while addressing the challenges posed by design complexity and material constraints.

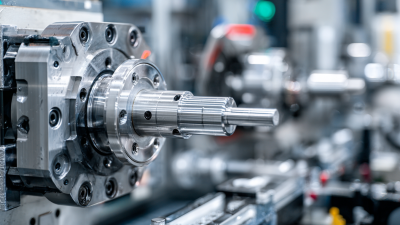

Injection molding is a crucial manufacturing process used to create parts with complex geometries and high precision. Understanding the basics of injection molding part design is essential for engineers and designers aiming to optimize production efficiency and product quality. Key factors to consider include material selection, part geometry, and wall thickness. A well-designed part should facilitate easy flow of the molten material while minimizing the risk of defects such as air traps and uneven cooling.

**Tips:** When designing parts for injection molding, keep wall thickness uniform to prevent warping and ensure consistent cooling. Additionally, incorporate draft angles in your design to aid in the ejection process, making it easier to remove parts from the mold without damaging them.

Another critical aspect of part design is the incorporation of features that support functionality while maintaining manufacturability. Designing for assembly and considering the use of inserts or fasteners can save time and resources. Effective use of ribbing can also enhance the structural integrity of parts without adding significant weight.

**Tips:** Utilize simulation tools to predict how the part will behave during molding. This can help identify potential issues early in the design process, allowing for adjustments that improve both performance and manufacturability.

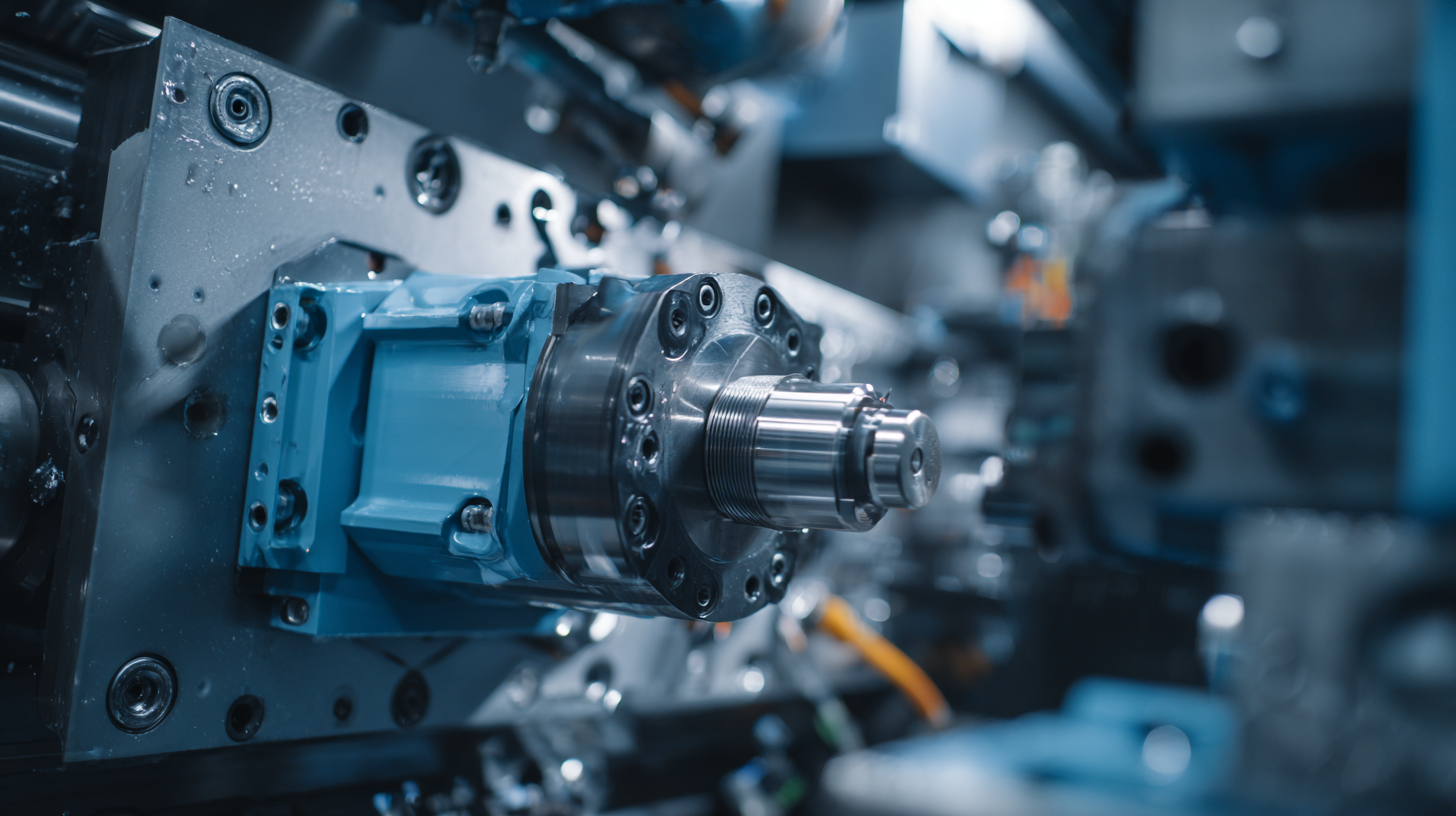

In the realm of modern manufacturing, the exploration of advanced materials is crucial for enhancing molding efficiency. Recent studies indicate that the use of high-performance polymers, such as polyethylene terephthalate (PET) and polycarbonate (PC), significantly reduces cycle times and improves part quality. According to the American Injection Molding Institute, incorporating these advanced materials has led to productivity increases of up to 30%, showcasing their integral role in optimizing injection molding processes.

Tip: When selecting materials, consider the thermal and mechanical properties that align with your application requirements to ensure optimal performance.

Moreover, the adoption of biocompatible materials is gaining traction, especially in the medical and consumer goods sectors. These materials not only provide excellent mechanical properties but also align with sustainability efforts. The global bioplastics market is projected to reach $22.9 billion by 2025, reflecting a growing trend toward environmentally responsible manufacturing practices. Manufacturers can enhance their efficiency and meet regulatory requirements by integrating advanced materials into their product designs.

Tip: Always conduct thorough testing to evaluate the interaction of new materials with existing production processes to maintain quality standards.

| Material Type | Moldability Rating | Cycle Time (sec) | Shrinkage Rate (%) | Cost per kg ($) |

|---|---|---|---|---|

| Polypropylene (PP) | 8/10 | 25 | 1.5 | 1.00 |

| Acrylonitrile Butadiene Styrene (ABS) | 9/10 | 30 | 0.8 | 1.25 |

| Polyethylene Terephthalate (PET) | 7/10 | 40 | 0.5 | 1.50 |

| Nylon 6/6 | 8/10 | 35 | 1.2 | 2.00 |

| Polycarbonate (PC) | 9/10 | 45 | 0.6 | 2.50 |

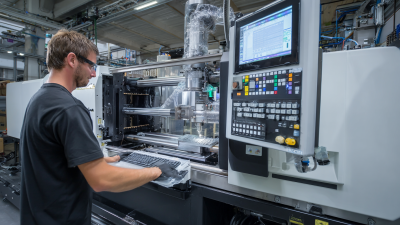

Modern manufacturing is witnessing a significant shift toward incorporating advanced simulation tools in the design workflow for injection molding part manufacturing. According to a report by Mordor Intelligence, the global injection molding market is expected to reach $246.83 billion by 2026, fueled by the need for efficient production and the ability to minimize waste during the design phase. Simulation tools enable engineers to predict the behavior of molded parts under various conditions, leading to more informed design decisions and optimized performance.

Utilizing simulation software, such as Autodesk Moldflow or SolidWorks Plastics, allows designers to visualize potential issues such as warping, shrinkage, and material flow before production begins. A study by the Plastic Industry Association indicates that companies integrating simulation into their design process can reduce material costs by up to 20% and improve time-to-market by as much as 30%. This optimization not only enhances the quality of the final product but also significantly accelerates the iterative design process, allowing firms to stay competitive in an ever-evolving market. By leveraging these innovative techniques, manufacturers can ensure their designs meet both functional and aesthetic requirements, positioning themselves for success in the modern landscape of production.

In the realm of modern manufacturing, implementing Design for Manufacturability (DFM) principles is crucial to optimize injection molding part design. As industries face pressure to minimize costs and complexity, DFM becomes a key strategy in enhancing production efficiency. Automotive manufacturers, for example, are harnessing DFM to streamline their processes, which not only cuts expenses but also propels innovation in electric vehicle design. This proactive approach ensures that products are not only designed efficiently but also align with the evolving demands of the market.

**Tips for Effective DFM Implementation:**

1. Involve cross-functional teams early in the design phase to gather diverse insights that can help identify potential manufacturing challenges.

2. Utilize advanced tools like simulation software to predict how design choices impact manufacturability, enabling proactive adjustments before physical production begins.

As companies increasingly recognize the value of a circular economy, adopting DFM principles can lead to new market opportunities. By prioritizing manufacturability, businesses can also reduce waste, thereby contributing to more sustainable production practices. This forward-thinking mindset not only drives immediate benefits but also positions companies advantageously in an ever-competitive landscape.

This chart illustrates the efficiency metrics related to various aspects of injection molding part design. It includes factors such as design complexity, material selection, production time, cost efficiency, and defect rate, highlighting the importance of implementing Design for Manufacturability (DFM) principles in modern manufacturing.

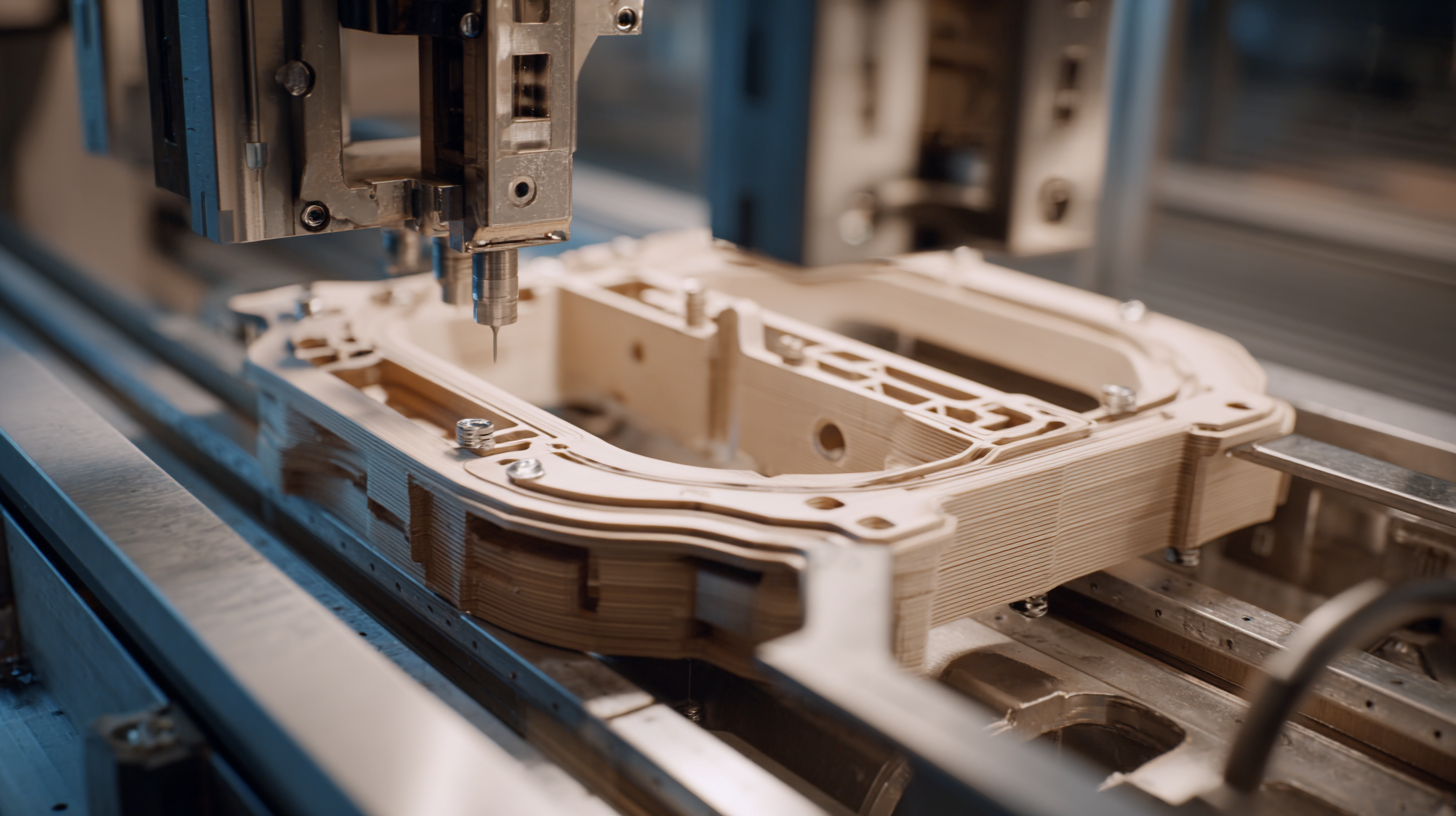

In modern manufacturing, the integration of 3D printing technologies into the injection molding process has revolutionized rapid prototyping. According to a recent report from the Wohlers Associates, the additive manufacturing market—which includes 3D printing—grew to $12.6 billion in 2020, indicating a remarkable shift towards faster and more cost-effective production methods. By using 3D printing for prototyping injection molds, manufacturers can significantly reduce lead time from weeks to just days, enabling quicker modifications and iterations during the design phase.

Moreover, leveraging 3D printing to create mold prototypes allows for intricate geometries that traditional injection molding techniques may struggle to achieve. Data from a study by the American Society for Quality (ASQ) suggests that companies employing 3D printed prototypes in their molding processes can achieve as much as a 70% reduction in material waste. This not only streamlines production efficiency but also aligns with sustainability goals, making 3D printing an invaluable tool in the quest for innovative and efficient injection molding part design in the competitive landscape of modern manufacturing.