When it comes to manufacturing, choosing the right method is essential. Large Scale Injection Molding stands out as a top choice for many businesses. This method offers significant advantages in efficiency and cost-effectiveness. It allows for the production of high-quality parts in large volumes, reducing production time and labor costs.

The process is versatile, accommodating various materials. From plastics to advanced composites, the flexibility of Large Scale Injection Molding meets diverse industry needs. However, companies must also consider their specific requirements before diving in. Initial setup costs can be high, and proper machinery is necessary for optimal results.

Manufacturers should reflect on the trade-offs. While the benefits can be substantial, each project demands careful planning and analysis. It is crucial to weigh the potential risks against the advantages. Ultimately, Large Scale Injection Molding can propel businesses forward when implemented thoughtfully.

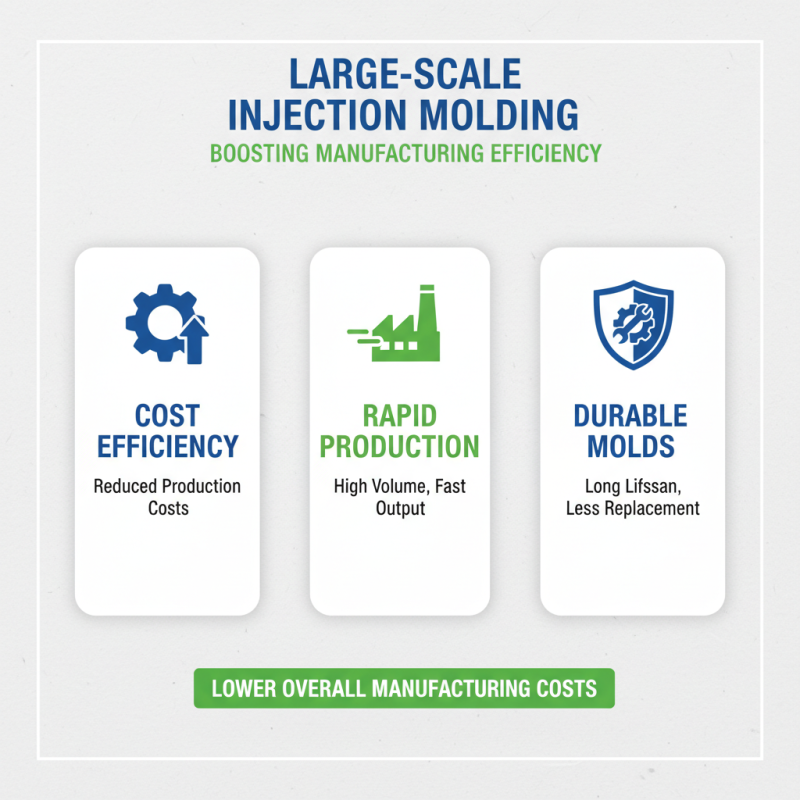

Large scale injection molding offers several key benefits that enhance manufacturing processes. The speed of production is a standout feature. According to a recent industry report, large scale systems can produce up to 30% more parts in the same amount of time compared to traditional methods. This efficiency is critical for meeting high demand.

Cost effectiveness is another significant advantage. A report from the Automotive Industry Association highlights that large scale injection molding can reduce manufacturing costs by nearly 20%. This is mainly due to lower material waste and faster processing times. However, businesses must analyze their production runs carefully. A large initial investment can deter some manufacturers.

Quality consistency plays a vital role in large scale injection molding. Uniformity in product quality can enhance brand reputation. Manufacturers report a 15% reduction in defects in parts produced using this method. However, achieving this consistency requires meticulous attention to mold design and material selection. Challenges in these areas can lead to unexpected failures. Further reflection is necessary to optimize these processes and reduce risks.

When considering large-scale injection molding, there are vital aspects to keep in mind. A report from the Plastics Industry Association states that injection molding accounts for over 60% of the total plastics manufacturing market. This statistic highlights its importance in the industry. However, understanding the specific needs of your production line is crucial.

One should not overlook production speed. Large-scale injection molding can achieve cycle times of less than 20 seconds per part. Yet, the actual speed can vary based on factors like material selection and mold complexity. Moreover, the cost of production can escalate quickly if these factors are miscalculated. Overspending on molds or materials can yield low returns.

Additionally, quality consistency is a critical consideration. Large-scale production requires rigorous quality control protocols. A report from Allied Market Research notes that 80% of manufacturers are looking to invest in quality management systems. However, inadequate inspections can lead to defects, impacting the entire production run. Achieving balance is key, but mistakes can happen, leading to waste and financial losses. Balancing speed, cost, and quality is a constant challenge in the injection molding realm.

Large scale injection molding offers numerous advantages over small scale molding. One significant benefit is efficiency in production. Large scale methods can produce thousands of parts quickly. This is crucial for businesses that need high-volume output. Smaller batch production lacks this speed, often resulting in higher costs per unit.

Quality consistency is another important factor. Large scale injection molding ensures that each part meets strict specifications. This uniformity reduces the risk of defects. In contrast, small scale molds might vary more due to the manual processes involved. However, small scale does excel in customization, allowing for unique designs. This aspect may appeal to niche markets.

Tips: Consider production volume when deciding on mold type. High-volume products may significantly benefit from large scale methods. Evaluate your design complexity; intricate designs may work better in small runs. Don’t overlook the importance of testing. Always assess sample outputs before committing to large orders. Making any changes post-production can be costly and time-consuming.

Large scale injection molding has become a cornerstone in various industries. Automotive manufacturers heavily rely on this method for producing complex parts efficiently. From bumpers to dashboards, the precision of injection molding ensures high-quality components. Aerospace also benefits greatly, using this technique for lightweight, durable parts.

Consumer goods are another area where large scale injection molding shines. Think of kitchen appliances and toys. These products often require mass production while maintaining uniformity. However, the process isn't without its challenges. Maintaining quality across thousands of units can lead to discrepancies. Minor flaws may arise, causing setbacks in production.

Electronics manufacturers frequently turn to injection molding for casing and components. The technology allows for intricate designs that meet safety standards. But, as with any manufacturing process, continuous monitoring is essential. Oversights can result in costly recalls. It’s imperative to balance speed and accuracy in this competitive field.

Large scale injection molding significantly enhances cost efficiency in manufacturing. This method allows for the rapid production of large quantities of parts. The molds are designed for high durability, reducing the need for frequent replacements. This long life leads to lower production costs over time.

Production speed is another advantage. With automated systems, parts can be produced quickly and accurately. Operators can handle multiple machines simultaneously. Thus, faster cycles translate to more units produced each day. However, it’s vital to consider the initial investment. The upfront costs for machines and molds can be high. Careful planning is essential to maximize returns.

Tips: Assess your production needs before investing. Consider potential future demand to avoid over or underproduction. Regularly review your production processes to identify any inefficiencies. This allows for continuous improvement and lower costs in the long run.