Marine Equipment Injection Molding is a crucial process in the maritime industry. It involves creating precise parts for ships and other marine vessels. This technique uses high-quality polymer materials. These materials ensure durability and resistance to harsh marine environments.

In recent years, the demand for effective marine solutions has increased. As a result, Marine Equipment Injection Molding has become more important. It provides a reliable method for producing complex components. However, there are challenges. Some manufacturers struggle with consistency and quality control. These issues can lead to significant setbacks.

Moreover, sustainability is a growing concern. The industry must adapt to eco-friendly practices. Balancing quality and environmental impact is not easy. Innovations are needed to enhance performance without harming marine ecosystems. Overall, Marine Equipment Injection Molding holds promise, but there is room for improvement.

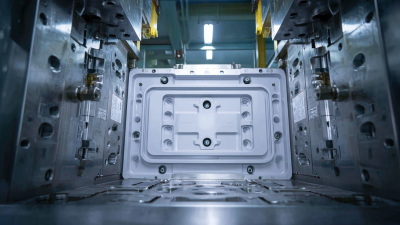

Marine equipment injection molding is a vital process in producing parts for the maritime industry. This technique involves injecting molten material into a mold to create specific shapes and designs. Using plastics and composites, manufacturers can produce durable components for boats, ships, and other marine vessels. The precision of the injection molding process allows for complex geometries, essential for functional marine parts.

With the harsh conditions at sea, marine equipment must withstand extreme temperatures and corrosion. Manufacturers need to select materials carefully. The wrong choice can lead to early failure of components. Quality control is essential throughout the injection molding process. Even a small flaw can compromise the performance and safety of marine equipment.

While injection molding provides many advantages, it also poses challenges. The initial investment for molds can be high, and production adjustments might be needed over time. Failure to adapt can result in wasted materials and resources. Continuous learning and improvement are crucial for manufacturers in this field. The importance of marine equipment injection molding is clear, but it requires diligence and innovation to keep up with industry demands.

Marine equipment injection molding is essential for creating durable and efficient components. Selecting the right materials drastically influences the performance and longevity of these products. Common materials used in marine injection molding include thermoplastics like polycarbonate and nylon. These materials offer excellent resistance to moisture and UV radiation, making them suitable for marine environments.

Polycarbonate, for instance, boasts high impact resistance, while nylon provides strength and flexibility. According to recent industry reports, the marine injection molding market is expected to grow by 5% annually. This highlights the increasing demand for quality marine components. Using advanced materials can lead to better designs and lower maintenance costs.

Tips: Always analyze material properties before selection. Consider factors like weight, durability, and cost. Testing prototypes can help identify potential issues early. Keep in mind that not all materials perform well in harsh conditions. There may be trade-offs between cost and quality. Balancing these factors is crucial for long-lasting marine equipment.

| Material | Properties | Applications | Environmental Impact |

|---|---|---|---|

| Polypropylene (PP) | Lightweight, chemical resistant, durable | Boat components, storage tanks | Recyclable, low impact |

| Polyethylene (PE) | Flexible, resistant to moisture and chemicals | Pipes, bumpers | Recyclable, minimal pollution |

| Polyvinyl Chloride (PVC) | Stiff, resistant to corrosion | Decking, enclosure parts | Can release toxic materials if incinerated |

| Nylon | Strong, abrasion resistant, low friction | Gear systems, ropes | Biodegradable alternatives available |

| Acrylonitrile Butadiene Styrene (ABS) | Impact resistant, toughness, lightweight | Covers, cabinets | Recyclable but needs proper disposal |

Injection molding is a revolutionary method in marine equipment production. It offers several advantages that significantly enhance manufacturing efficiency. This process allows for the creation of complex shapes and designs, which are often essential in marine applications. According to industry reports, injection molding can reduce production time by up to 50%. This efficiency leads to lower labor costs and faster market delivery.

The ability to use various materials is another significant advantage. Manufacturers can choose from different polymers, enabling them to optimize durability and weight. For instance, lighter materials can improve fuel efficiency. This choice helps in creating components that withstand harsh marine environments. However, a focus solely on cost reduction may compromise quality. Quality control remains crucial to avoid failures in critical components.

Tips: Always prioritize quality over speed. Regularly review your material choices to ensure they meet industry standards.

Sustainable practices are increasingly important. Injection molding generates less waste compared to other manufacturing methods. However, companies should also consider the environmental impact of the materials used. The industry is moving towards adopting recyclable polymers, which could align with future regulatory changes. Balancing sustainability with performance is a challenge that requires continuous assessment.

Marine equipment manufacturing is governed by strict industry standards and regulations. These ensure safety, reliability, and environmental protection. Manufacturers must adhere to guidelines that dictate materials, testing procedures, and design specifications. Failure to meet these standards can lead to risks, including equipment failure and accidents at sea.

Different organizations oversee compliance in marine equipment. These include both international and national bodies. They require regular audits and certifications. These processes can be time-consuming and costly. Smaller manufacturers may struggle to keep up. Yet, adherence is crucial for building trust with customers.

Innovation often challenges existing regulations. New materials and technologies can create gaps in compliance. For instance, the introduction of lightweight composites may not fit existing frameworks. This can lead to confusion and a need for updated standards. Manufacturers must stay informed and adaptable. Meeting regulations is an ongoing process, not a one-time task.

This chart illustrates the distribution of material types used in marine equipment injection molding, reflecting the industry's standards and regulations.

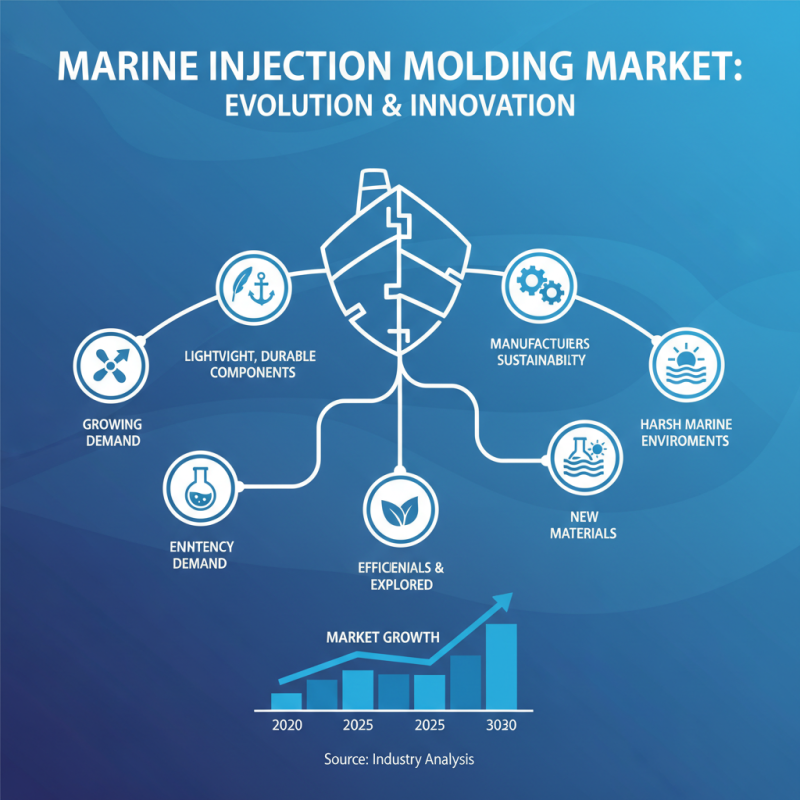

The marine injection molding market is evolving. It plays a significant role in producing various equipment for boats and ships. As the demand for lightweight, durable components grows, manufacturers are adapting their processes. The focus is on efficiency and sustainability. Companies are exploring new materials that can withstand harsh marine environments.

Trends indicate a shift towards incorporating advanced technologies. Automation and robotics are being used to enhance production rates. However, challenges remain. Many manufacturers face difficulties in keeping up with rapid changes. The need for skilled labor is increasing, which complicates matters further.

Looking ahead, eco-friendly practices will likely dominate. Recycling and reducing waste will become crucial. Manufacturers must pay close attention to regulations that could impact production. The future of marine injection molding is promising but requires ongoing innovation and adaptation. Companies that can meet these challenges will thrive.