The automotive industry is undergoing a transformative shift, with manufacturers increasingly relying on advanced technologies to meet the evolving demands for efficiency, performance, and sustainability. According to a recent report by MarketsandMarkets, the global automotive plastic market is projected to reach USD 67.45 billion by 2026, growing at a CAGR of 8.3% from 2021 to 2026.

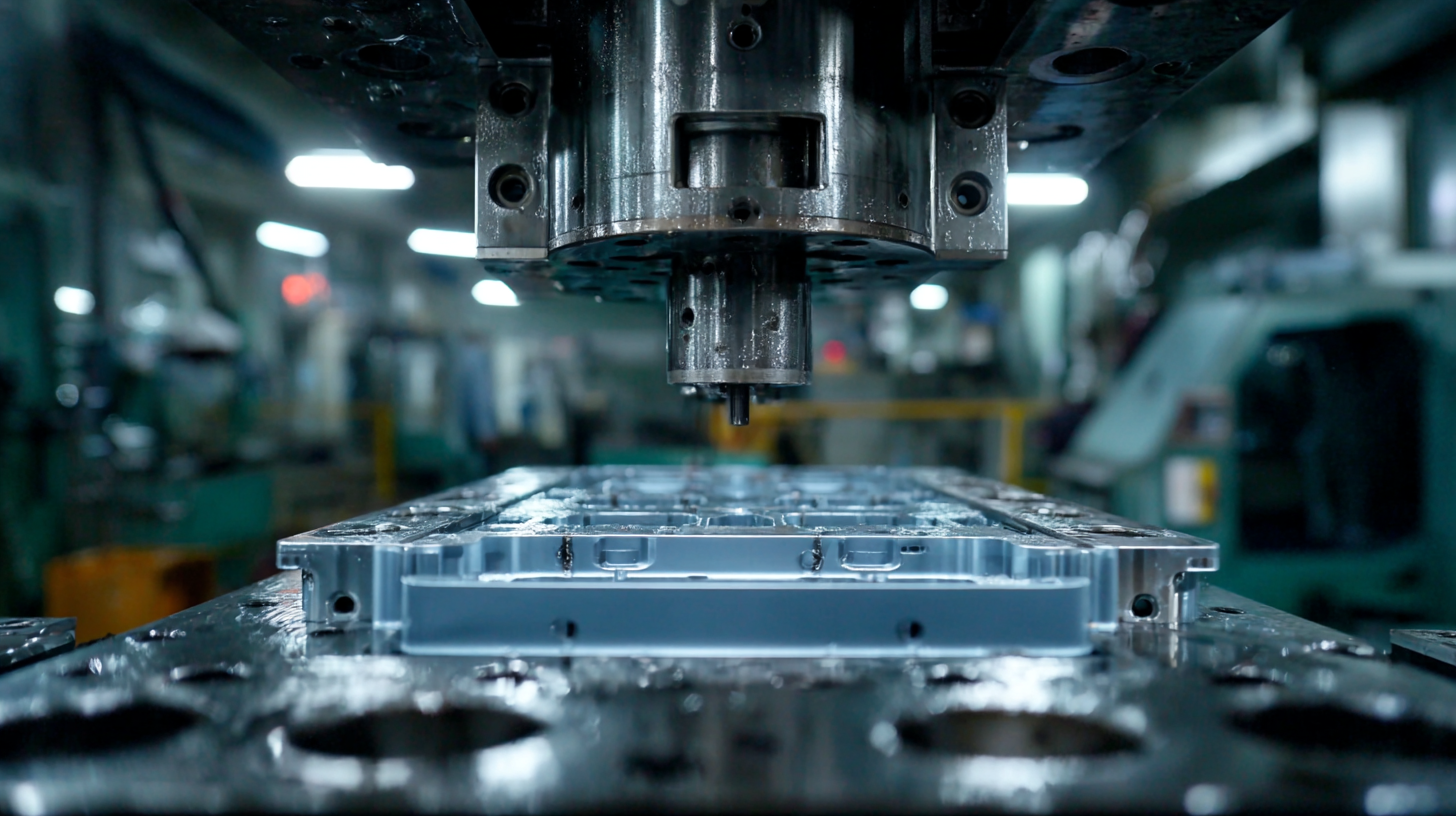

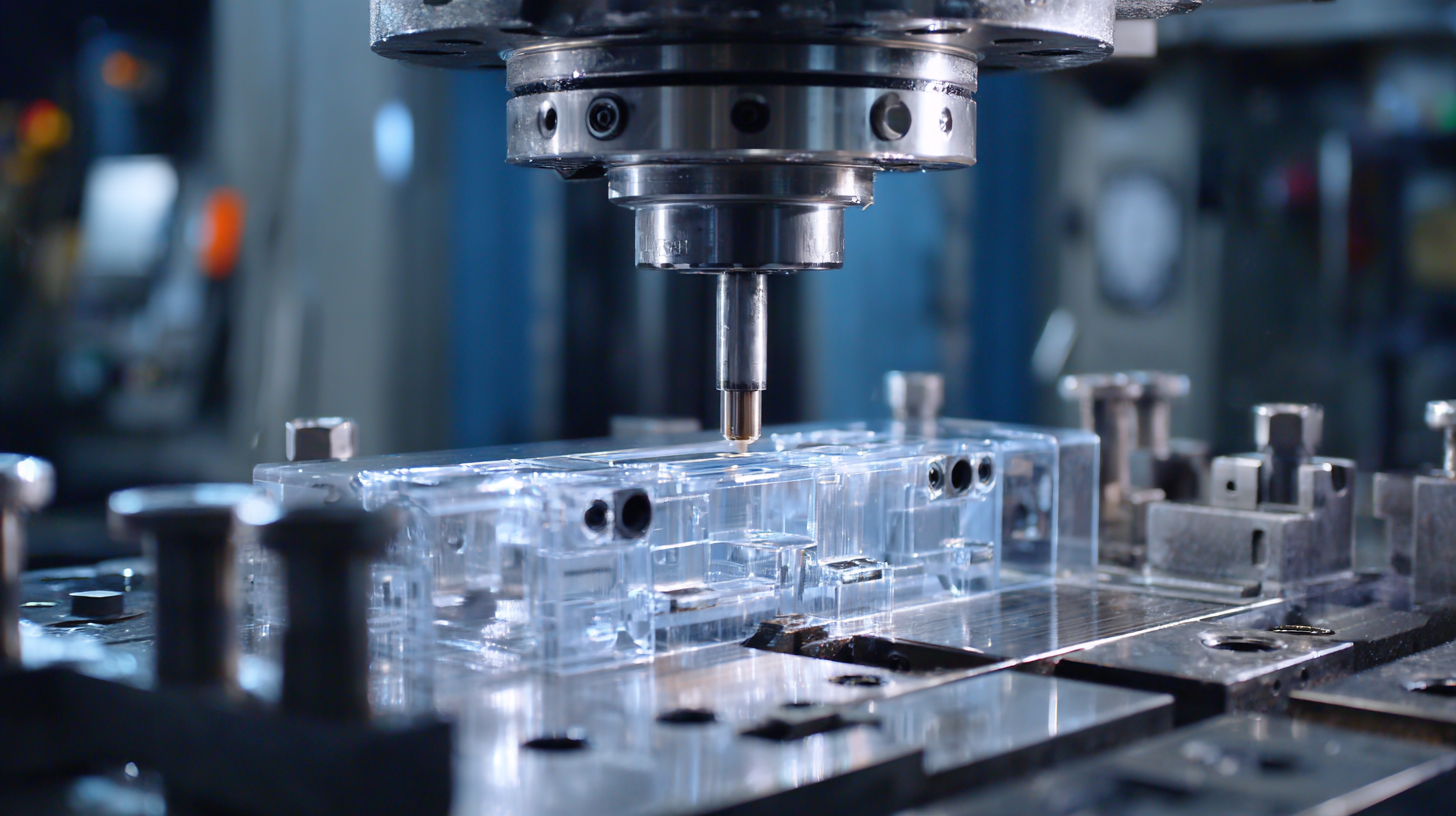

A critical component of this growth is the effectiveness of Automotive Exterior Injection Plastic Part Molding, which allows manufacturers to produce lightweight, durable, and aesthetically pleasing components that enhance vehicle designs while reducing costs. As an Automotive Exterior Injection Plastic Part Molding Manufacturer, mastering this intricate process not only drives operational efficiency but also positions companies to leverage innovative solutions that cater to the stringent requirements of modern automotive engineering.

This blog delves into the complexities of automotive exterior injection molding, exploring techniques, challenges, and best practices that define success in this essential manufacturing sector.

The automotive industry has seen a significant shift towards the use of plastic components, particularly in exterior applications where weight reduction and design flexibility are crucial. Automotive exterior injection plastic molding has become an essential technique for manufacturers aiming to produce lightweight, durable, and aesthetically pleasing parts. According to a recent report by Grand View Research, the global market for automotive injection molded plastics is expected to reach USD 45.8 billion by 2027, growing at a CAGR of 4.8%. This growth is being driven by increasing demand for fuel-efficient vehicles that leverage advanced material technologies.

Understanding the fundamentals of automotive exterior injection molding techniques is vital for manufacturers looking to optimize their production processes. Key methods such as gas-assisted injection molding and structural foam molding allow for the production of complex shapes with reduced material usage, leading to lower costs and enhanced performance. The American Chemistry Council indicates that plastic components can reduce vehicle weight by approximately 30% compared to metal, translating into a significant improvement in fuel efficiency—up to 15% in some cases. As the industry moves towards more sustainable practices, mastering these molding techniques will be crucial for manufacturers to stay competitive and meet the evolving demands of consumers.

Designing plastic components for automotive applications is a multifaceted process that demands careful consideration of several key factors. One of the foremost considerations is the specific

performance requirements

of the component under various environmental conditions. Components must exhibit durability, resistance to temperature fluctuations, and the ability to withstand harsh chemicals typically found in automotive environments. Manufacturers must prioritize these attributes during the design phase to ensure

longevity and reliability

in the final product.

Additionally, the aesthetics of plastic components cannot be overlooked. In the automotive industry, the

visual appeal

of a vehicle significantly influences consumer decisions. Manufacturers need to strike a balance between functional and aesthetic considerations, ensuring that the plastic parts not only perform well but also enhance the overall design of the vehicle. Color matching, surface finish, and texture are

crucial elements

that must be carefully managed to meet the design vision of the automotive brand. By integrating these considerations into the design process, manufacturers can create components that align with both functional performance and consumer expectations.

In the competitive landscape of automotive manufacturing, optimizing the injection molding process is crucial for enhancing efficiency and product quality. A recent report indicates that manufacturers can reduce cycle times by up to 30% through effective process management and advanced technology integration. For instance, implementing real-time data analytics in injection molding machines allows for more precise adjustments, minimizing defects and waste. With the ever-growing demand for lightweight and durable materials, the transition to high-performance polymers continues to gain traction, helping manufacturers meet stringent automotive standards.

Moreover, as industries explore the potential of innovative manufacturing techniques, the rise of ceramic 3D printing is noteworthy. While traditionally known for its brittleness, advancements in ceramic materials now offer enhanced thermal stability and corrosion resistance, providing solutions in high-stress automotive environments. Reports suggest that the integration of such advanced materials into the injection molding process could pave the way for producing components that not only withstand extreme conditions but also significantly improve the overall vehicle performance. As manufacturers strive for sustainability and efficiency, the fusion of cutting-edge materials with optimized molding techniques will be key to remaining competitive in the automotive sector.

The automotive industry is witnessing a significant shift towards advanced plastic molding techniques, particularly within the realm of exterior components. However, manufacturers often face common challenges in automotive plastic molding, including material selection, design complexity, and the need for precision in production processes. To address these issues, it is essential to adopt innovative approaches and technologies. According to industry reports, the global metal powder market is projected to grow from $7.99 billion in 2024 to $13 billion by 2032, indicating a broader trend in the adoption of high-performance materials that could enhance the plastic molding process.

Additionally, trends in the electric vehicle sector reveal a growing demand for lightweight and durable materials, as companies strive to meet stringent environmental regulations. The production of additive manufacturing equipment has surged, with data showing a 44.9% increase in output in the first quarter of this year alone. This indicates a strong inclination towards sustainable practices and the continual evolution of manufacturing processes that prioritize efficiency and quality in automotive plastic components. By leveraging these advancements, manufacturers can overcome the prevalent challenges and enhance their production capabilities in automotive exterior injection plastic molding.

As the automotive industry evolves, the future of exterior injection molding increasingly integrates cutting-edge technologies and sustainable practices. Manufacturers should be aware of the growing trend towards lightweight materials, such as advanced composites and bio-based plastics, which not only enhance fuel efficiency but also meet stringent environmental regulations. This shift not only helps automakers achieve sustainability goals but also appeals to eco-conscious consumers seeking environmentally friendly vehicles.

Moreover, the adoption of smart manufacturing technologies, including automation and digital twin modeling, is revolutionizing the injection molding process. These advancements allow manufacturers to optimize production efficiency, reduce waste, and improve the overall quality of automotive parts. By investing in these technologies, manufacturers can stay competitive in a rapidly changing market and respond more effectively to consumer demands for customization and rapid prototyping. Embracing these future trends will be crucial for players in the automotive industry aiming to succeed in the digital era.