The automotive industry is undergoing a significant transformation, with innovations like Plastic Injection Molding Automotive leading the charge. According to a report by MarketsandMarkets, the automotive plastics market is projected to reach $47.74 billion by 2026, growing at a CAGR of 8.9%. This growth underscores the increasing reliance on lightweight materials that enhance fuel efficiency and reduce emissions. Plastic injection molding has emerged as a key manufacturing process, enabling the production of complex, high-precision components at reduced costs and shorter lead times. As vehicle designs evolve towards more intricate shapes and functionalities, the versatility and durability of plastic components are becoming indispensable. This technological advancement not only addresses the stringent regulations on vehicle weight and emissions but also supports sustainability initiatives through the use of recyclable materials. Thus, Plastic Injection Molding is not just a manufacturing method; it is a vital player in redefining modern vehicle production and performance.

The automotive industry is undergoing a significant transformation, and plastic injection molding is at the forefront of this change. With the rising demand for fuel-efficient vehicles, manufacturers are increasingly turning to plastic components to reduce overall vehicle weight. According to a report by the American Chemistry Council, lightweight automotive plastics can account for up to 50% of a vehicle's total weight reduction, leading to enhanced fuel efficiency. This is particularly important as the automotive sector aims to meet stricter emissions regulations while improving performance.

The integration of advanced plastic injection molding techniques allows automakers to create intricate and lightweight designs that were previously unattainable with traditional materials. A study conducted by the Society of Automotive Engineers notes that vehicles made with high-performance plastics can achieve a weight reduction of approximately 30% compared to their metal counterparts. This reduction directly contributes to a decrease in fuel consumption, with estimates suggesting that every 10% reduction in vehicle weight can lead to a 6-8% increase in fuel economy. As such, the role of plastic injection molding is not only pivotal in reshaping vehicle design but also essential in the quest for greater sustainability in the automotive landscape.

The automotive industry is undergoing a significant transformation, with plastic injection molding at the forefront of innovation. One of the essential aspects of this advancement is the durability and chemical resistance of plastic components used in modern vehicle design. These components are engineered to withstand harsh environmental conditions, extreme temperatures, and exposure to various chemicals, ensuring that vehicles maintain their integrity and performance over time.

Plastic injection molding allows manufacturers to create sturdy parts that meet rigorous standards while also reducing weight, which is crucial for fuel efficiency. Advanced materials like glass-filled nylon and polycarbonate are increasingly used due to their exceptional mechanical properties and resistance to corrosive substances. As a result, vehicles can incorporate complex designs that enhance both functionality and aesthetics without compromising on durability.

Tips: When selecting plastic components for automotive design, consider the specific environmental stresses and chemical interactions they will encounter. Investing in high-quality materials can significantly extend the lifespan of parts and contribute to overall vehicle reliability. Additionally, conducting thorough testing on prototypes can help identify potential weaknesses before mass production.

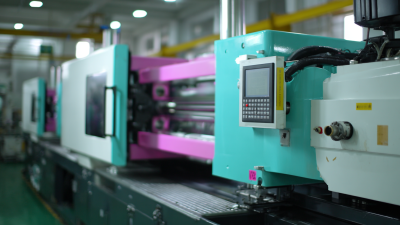

The integration of advanced manufacturing technologies, particularly automation, is transforming plastic injection molding processes in the automotive industry. Automation enhances efficiency by reducing cycle times and minimizing errors, which is crucial for maintaining the high production rates required by modern vehicle manufacturing. Automated systems can manage tedious tasks such as material handling, machine setup, and quality control, allowing manufacturers to allocate human resources to more complex, value-added activities. This shift not only improves productivity but also ensures consistent quality in the production of automotive components.

Moreover, the implementation of robotics and intelligent systems in injection molding processes facilitates real-time monitoring and data analysis. By utilizing sensors and connected devices, manufacturers can gather valuable insights into operational performance, enabling proactive maintenance and reducing downtime. The adaptability of automated injection molding systems allows for rapid reconfiguration to accommodate new designs and varying production volumes, which is essential for meeting the evolving demands of the automotive market. This synergy between automation and plastic injection molding is paving the way for more innovative, efficient, and sustainable vehicle production practices.

Plastic injection molding has become a pivotal technique in the automotive industry, contributing significantly to cost savings and efficiency. Traditional materials like metals and wood have long been staples in vehicle production; however, they often come with higher material costs, labor expenses, and longer manufacturing times. In comparison, plastic injection molding allows for the rapid production of intricate designs at a fraction of the cost. This shift not only reduces the overall weight of the vehicles, leading to improved fuel efficiency, but also enhances recyclability, aligning with sustainability goals.

**Tips for Cost-Effectiveness:**

1. Focus on parts design — Optimize your designs for the injection molding process to reduce waste and fabrication time.

2. Choose the right materials — Selecting high-quality, lightweight plastics can lead to better performance and lower overall costs.

3. Evaluate the entire lifecycle — Consider the long-term savings in maintenance and fuel efficiency when opting for plastic components over traditional materials.

By embracing plastic injection molding, automakers can drive down production costs while continuing to innovate. The ability to produce complex shapes and components swiftly positions this technology as a key player in future automotive design and manufacturing.

The automotive industry is witnessing a significant transformation driven by the increasing demand for lightweight and fuel-efficient vehicles. This shift towards more sustainable options is creating substantial growth opportunities in the market. Manufacturers are focusing on enhancing vehicle performance and fuel economy by integrating advanced plastic injection molding techniques, which allows for the use of innovative, high-performance thermoplastics. These materials not only reduce the weight of vehicles but also contribute to improved recyclability in the production process.

In line with global sustainability goals, the incorporation of eco-friendly plastics is becoming a crucial aspect of car production. As the industry strives to meet stricter environmental regulations and consumer expectations, the use of recyclable materials is on the rise. This is particularly evident in the production of electric vehicles, where lightweight components can lead to increased range and energy efficiency. The ongoing development and application of modified plastics in automotive manufacturing not only support the lighter designs required for new energy vehicles but also promote a greener future for the industry.