The demand for high-quality custom plastic parts is ever-increasing across various industries, making the role of injection molding companies more crucial than ever. Experts in the field highlight the finesse and precision required to deliver excellence in plastic manufacturing. According to Dr. Sarah Thompson, a leading expert in polymer engineering, "The success of any project relying on plastic parts hinges on selecting the right injection molding companies that prioritize quality, innovation, and customer service."

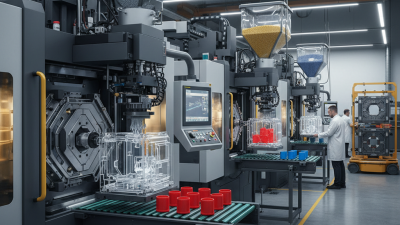

As industries strive for efficiency and reduced production costs, the significance of partnering with top-tier injection molding companies cannot be overstated. These companies are not only responsible for transforming raw materials into functional components but also for adhering to stringent quality standards that meet the specific needs of their clients. Furthermore, advancements in technology have propelled these companies into a new era of capabilities, allowing for rapid prototyping and complex designs that were previously unattainable.

In this article, we will explore the leading injection molding companies renowned for their commitment to delivering high-quality custom plastic parts. We will examine the factors that set these companies apart, including their innovative processes, quality control measures, and customer-centric approaches, ultimately guiding readers toward informed choices in their manufacturing endeavors.

The injection molding industry plays a crucial role in the manufacturing of high-quality custom plastic parts across various sectors, including automotive, consumer goods, and medical devices. As companies strive for efficiency and precision, the demand for advanced injection molding technologies has surged. This has led to significant investments in research and development, resulting in innovative processes that enhance production speeds while minimizing waste. The use of computer-aided design (CAD) and simulation software has become commonplace, allowing manufacturers to optimize mold designs and foresee potential production challenges before they arise.

In this competitive landscape, quality control has emerged as a focal point. Top injection molding companies employ rigorous testing and quality assurance protocols to ensure that each product meets stringent industry standards. This commitment to quality is not only vital for compliance but also crucial for building long-lasting relationships with clients. Moreover, sustainable practices are increasingly being adopted, with a growing emphasis on using environmentally friendly materials and reducing energy consumption during the manufacturing process. As the industry evolves, these factors will continue to shape the strategies of leading players in the injection molding market, highlighting the continuous pursuit of excellence in producing custom plastic components.

When selecting high-quality custom plastic parts manufacturers, several key factors should be considered to ensure optimal results. Firstly, the manufacturer's experience and expertise in injection molding technology are crucial. According to a report by MarketsandMarkets, the global injection molding market is projected to grow from $226 billion in 2020 to $290 billion by 2025, signifying the increasing demand for skilled manufacturers. Choosing a company with a proven track record in producing complex parts can significantly impact the functional and aesthetic quality of the final product.

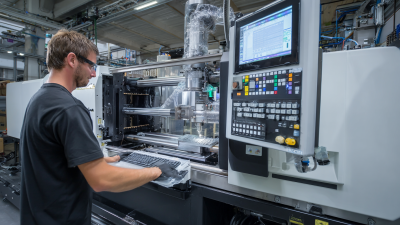

Another essential consideration is the availability of advanced technologies and capabilities. Manufacturers that utilize state-of-the-art machinery and processes, such as robotic automation and real-time monitoring, are more likely to deliver consistent quality. A study published by Grand View Research highlights that the adoption of innovative techniques can enhance production efficiency by as much as 20%. Furthermore, the ability to offer a range of materials and customizable options allows for versatility in product design, essential for meeting specific client requirements. Evaluating these factors will lead to selecting a partner who can provide high-quality custom plastic parts tailored to your project's needs.

| Company Size | Annual Revenue (in millions) | Years in Business | Certifications | Customer Satisfaction Rating |

|---|---|---|---|---|

| Small | 5 | 10 | ISO 9001 | 4.5/5 |

| Medium | 20 | 15 | ISO 13485, TS 16949 | 4.7/5 |

| Large | 150 | 25 | ISO 9001, ISO 14001 | 4.8/5 |

| Startup | 1 | 1 | N/A | 4.0/5 |

As we venture into 2023, the injection molding industry is witnessing remarkable advancements driven by innovative technologies that promise to enhance efficiency and product quality. A recent report from the Markets and Markets research firm predicts that the global injection molding market will reach approximately $380 billion by 2025, growing at a CAGR of 5.5%. This growth is largely attributed to the integration of smart manufacturing technologies, including the Internet of Things (IoT) and automation, which streamline production processes and minimize human error.

One significant trend is the adoption of 3D printing techniques in conjunction with traditional injection molding. This hybrid approach allows companies to create complex prototypes quickly and cost-effectively, revolutionizing the product development cycle. According to a report by Grand View Research, the 3D printing segment for injection molding is expected to see a compound annual growth rate of over 20% in the next five years, indicating a shift in how design and manufacturing converge.

Tips for companies looking to enhance their injection molding processes include investing in real-time monitoring systems to track machine performance and optimize workflow. Additionally, exploring sustainable materials, such as bioplastics, can not only reduce environmental impact but also cater to the increasing consumer demand for eco-friendly products. Staying ahead of these trends will not only enhance production capabilities but also ensure that businesses remain competitive in a rapidly evolving market.

In the realm of injection molding, quality assurance is paramount to ensure that custom plastic parts meet the necessary standards and specifications. Companies engaged in this sector must adhere to a variety of quality assurance protocols, including ISO certification processes, to deliver products that not only function as intended but also comply with industry-specific regulations. These standards begin from the initial design phase and span through materials sourcing, production processes, and final quality checks. Effective quality management systems facilitate ongoing evaluation, enabling companies to identify potential issues early in the production cycle.

Moreover, companies must implement stringent testing methodologies throughout the manufacturing process. This may involve rigorous inspections of raw materials, regular audits of machinery, and thorough testing of finished products to ensure they meet durability, strength, and tolerances specified by clients. Additionally, adherence to environmental and safety standards is essential, not only to protect workers but also to minimize the ecological impact of the production processes.

By fostering a culture of quality and responsibility, injection molding companies can assure their clients of the high standards maintained in the production of custom plastic parts, ultimately contributing to the reliability and reputation of their products in the marketplace.

Sustainability has become an essential consideration in modern injection molding practices as the industry seeks to minimize its environmental footprint. Companies are increasingly adopting eco-friendly materials, such as bioplastics and recycled polymers, which help reduce reliance on fossil fuels and lower greenhouse gas emissions. By utilizing these sustainable materials, manufacturers not only contribute to environmental preservation but also attract environmentally conscious consumers who prioritize sustainable products.

Moreover, incorporating energy-efficient technologies in the injection molding process has just as significant an impact. Advanced machinery and optimized production techniques can significantly reduce energy consumption and waste generation. Companies are investing in automated systems and smart manufacturing solutions that track and analyze resource usage, leading to more efficient operations. This commitment to sustainability not only enhances a company's reputation but also often results in cost savings in the long run, proving that eco-friendly practices can align with economic viability in the competitive landscape of custom plastic part production.

This chart illustrates the percentage of companies focusing on sustainable practices in the injection molding industry, highlighting the growing importance of sustainability in manufacturing processes.