In the ever-evolving automotive industry, the importance of high-quality manufacturing processes cannot be overstated. One of the key components driving this innovation is Automotive Interior Injection Plastic Part Molding, a technology that meets the rigorous demands of global suppliers. According to a report by MarketsandMarkets, the global automotive plastic market is projected to reach $42.4 billion by 2026, highlighting the shift towards lightweight and durable materials in vehicle production. The integration of advanced injection molding techniques not only enhances the aesthetic appeal and functionality of automotive interiors but also significantly contributes to cost efficiency and sustainability. With top-tier Chinese manufacturers leading the way, this specialized molding process is essential for ensuring that automotive suppliers can deliver top-notch products that meet both consumer expectations and industry standards.

The importance of plastic part molding in automotive interiors cannot be overstated. As vehicle manufacturers increasingly focus on enhancing the customer experience, they are turning to advanced materials and processes that ensure high-quality interior components. A recent study highlighted the optimization of injection molding processes for automotive oil filter housings, which not only improved product performance but also emphasized the role of materials like PA6.6 in achieving better structural integrity and durability. Such improvements are critical as the industry shifts towards sustainable practices, with recycled plastics playing a key role in meeting the growing demand for eco-friendly solutions.

In line with this trend, innovative approaches to design and manufacturing processes have emerged. A comprehensive Squeak and Rattle simulation tool has been employed to streamline development, allowing manufacturers to achieve 'right the first time' designs and thereby minimize rework and costs. According to recent surveys, the demand for easy-to-maintain and sustainable materials in automotive interiors is rising, driven by consumer preferences and regulatory pressures. As electric vehicles capture a larger market share, the aesthetic and tactile quality of materials will increasingly influence purchasing decisions, making effective plastic part molding not just important, but essential for competitive success in the automotive sector.

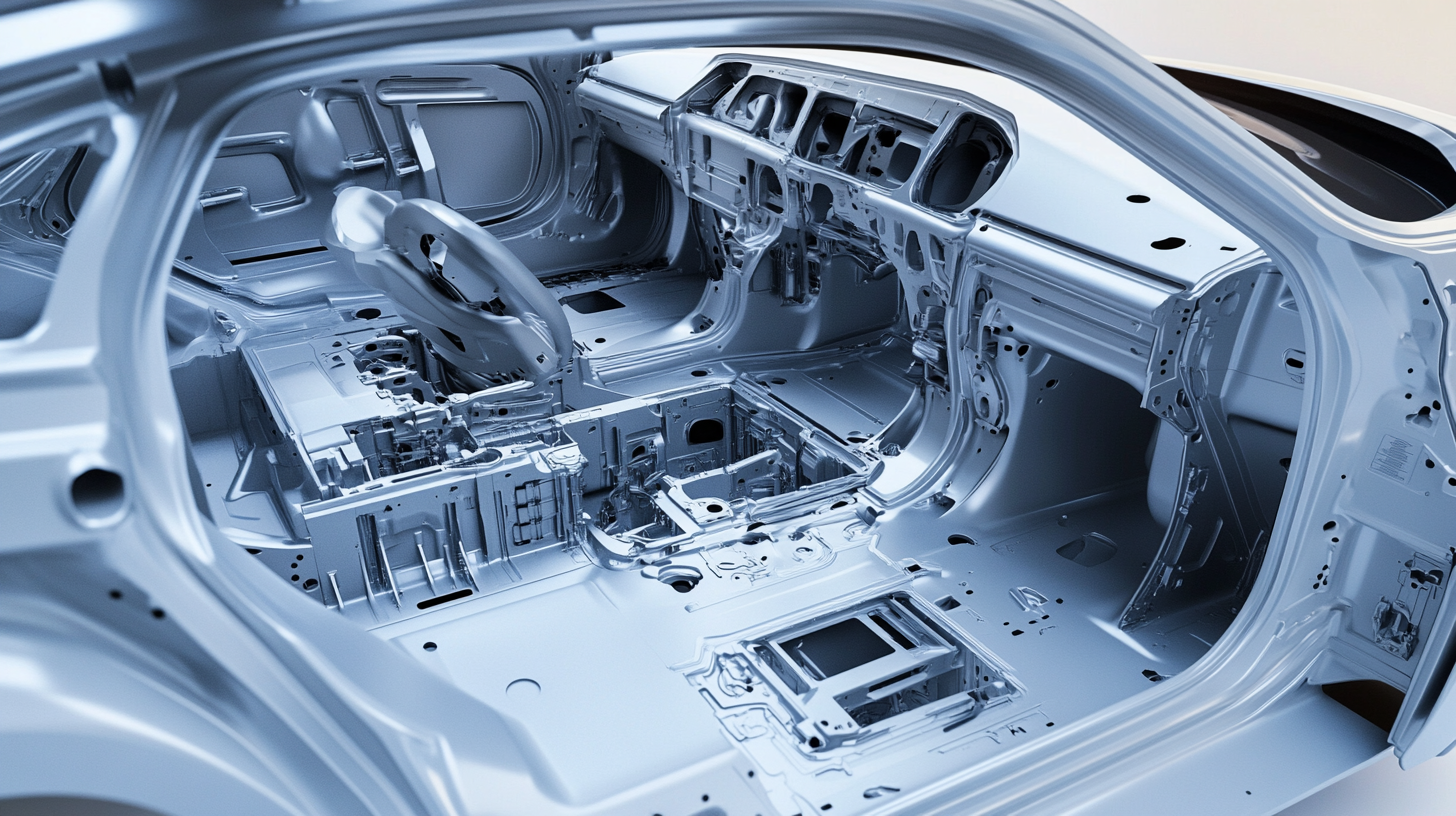

High-quality injection molding plays a crucial role in the automotive interior sector, particularly for global suppliers aiming to meet industry demands effectively. One key advantage of using top-notch injection molding is its ability to produce complex geometries with high precision. This is vital for automotive interiors, where intricate designs and tight tolerances are essential for both aesthetic appeal and functional performance. Moreover, advanced injection molding techniques enable manufacturers to use a variety of materials, allowing for enhanced durability and lightweight components that contribute to overall vehicle efficiency.

Another significant benefit of high-quality injection molding is its cost-effectiveness in large-scale production. By optimizing the manufacturing process, global suppliers can achieve shorter lead times and reduced waste, thereby increasing their competitive edge in the marketplace. Additionally, the consistency and reliability of parts produced through injection molding ensure that the final products meet rigorous quality standards. This reliability is especially important in the automotive industry, where safety and performance are paramount, making injection molding not just a manufacturing choice, but an essential element in the production of superior automotive interiors.

| Reason | Description | Key Benefit | Global Impact |

|---|---|---|---|

| Cost Efficiency | Reduced production costs through efficient mass production. | Lower prices for consumers and higher margins for suppliers. | Boosts competitiveness in the global marketplace. |

| Precision | Highly accurate fitting and detailing of parts. | Improves product quality and longevity. | Enhances brand reputation worldwide. |

| Material Versatility | Ability to utilize various engineering plastics and composites. | Allows customization for different vehicle models. | Supports diverse automotive requirements globally. |

| Sustainability | Reductions in waste and energy consumption through optimized processes. | Promotes eco-friendly practices in manufacturing. | Aligns with global sustainability goals. |

| Rapid Prototyping | Quick turnaround for designs into physical parts. | Accelerates time-to-market for new products. | Enhances innovation and responsiveness in the market. |

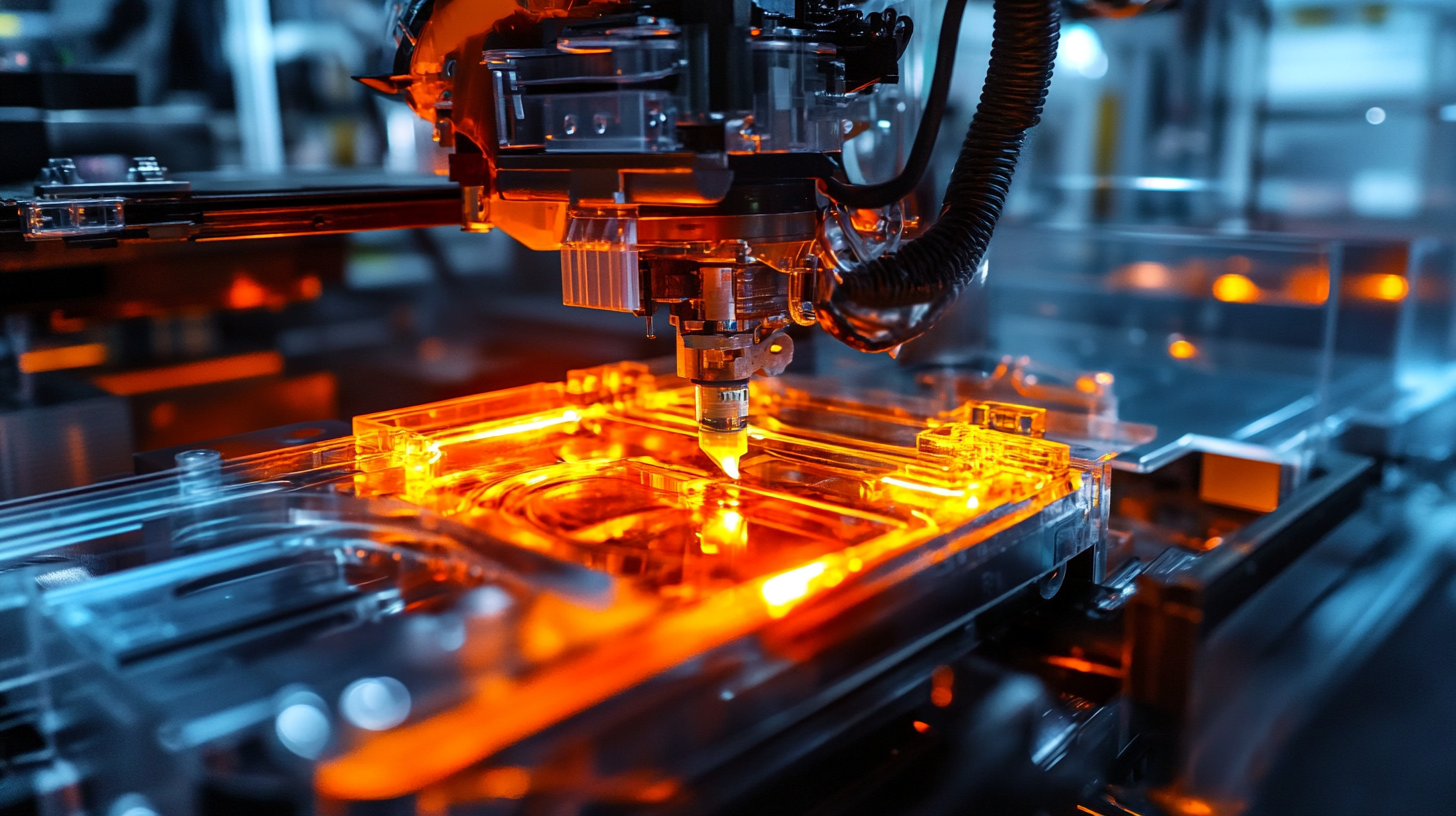

In recent years, innovative technologies have revolutionized the production of automotive interior plastic parts, leading to more efficient and sustainable manufacturing processes. Advanced injection molding techniques, such as the use of smart robotics and automated quality control systems, enable manufacturers to produce complex geometries with exceptional precision. These advancements not only enhance the quality and durability of the parts but also significantly reduce production times and waste, making them an attractive option for global suppliers.

Moreover, the integration of sustainable materials and eco-friendly practices in the plastic molding process is shaping the future of automotive interiors. Suppliers are increasingly adopting bioplastics and recycled materials, which not only meet consumer demand for environmentally responsible products but also comply with global regulations. By utilizing cutting-edge technologies and sustainable practices, automotive manufacturers can enhance the aesthetic appeal and functionality of their interior components, ultimately leading to improved consumer satisfaction and competitive advantage in the marketplace.

In the automotive industry, the demand for high-quality interior components has never been greater, and ensuring consistency in production is crucial for global suppliers. Injection molding has emerged as a key technology for achieving this consistency, allowing manufacturers to produce complex plastic parts with high precision. According to a recent report by MarketsandMarkets, the automotive plastics market is expected to reach $42.8 billion by 2025, highlighting the increasing reliance on plastic components in vehicle interiors.

Quality control in automotive interiors is paramount, as any defects can lead to significant safety concerns and increased recalls. Injection molding not only enhances the fidelity of production but also minimizes variability by providing repeatable precision in part production. The American Society for Testing and Materials (ASTM) emphasizes that consistent molding techniques can reduce the failure rates of components by up to 30%, demonstrating the importance of adopting advanced molding methods. By employing reliable injection molding processes, automotive suppliers can ensure that their products meet strict industry standards while also delivering aesthetic and functional qualities that resonate with consumers.

In recent years, plastic injection molding has emerged as a game-changer in the automotive interior design landscape. This innovative manufacturing process not only allows for intricate designs and complex geometries but also enhances the overall functionality and aesthetic appeal of vehicle interiors. As automotive manufacturers strive for greater customization options to cater to diverse consumer preferences, the ability to produce high-quality plastic parts efficiently makes injection molding an essential technology.

Moreover, the trends shaping the future of automotive interiors are leaning towards sustainability and lightweight materials. Advancements in plastic injection molding techniques have made it possible to utilize recycled materials without compromising quality. This aligns with the growing demand for eco-friendly solutions in the automotive industry. As manufacturers integrate smart technologies and ergonomic designs into vehicle interiors, the capability of injection molding to accommodate these innovations will be crucial. The flexibility of the process allows for rapid prototyping and shorter production times, ensuring that suppliers can meet the evolving demands of the market effectively.