In the competitive landscape of marine manufacturing, companies are continuously seeking ways to enhance efficiency and reduce operational costs. Marine Injection Molding has emerged as a pivotal technology in this endeavor, offering distinct advantages that can significantly improve production processes. According to a recent report by the American Society for Testing and Materials (ASTM), the adoption of advanced injection molding techniques in the marine sector can yield up to a 30% reduction in material waste and a 20% increase in production speed. Furthermore, a study by the Marine Industry Association highlights that manufacturers utilizing Marine Injection Molding have reported improved product durability and consistency, essential factors for meeting the rigorous standards of marine applications. This blog will delve into the various benefits of Marine Injection Molding and explore how it serves as a solution for enhancing operational efficiency in the industry.

Marine production is undergoing a significant transformation with the adoption of injection molding techniques, which enhance efficiency and streamline the manufacturing process. According to a report by MarketsandMarkets, the global injection molding market for marine applications is expected to grow at a CAGR of 5.6% from 2021 to 2026. This growth is largely attributed to the rising demand for lightweight and durable materials in boat building, which enables manufacturers to produce parts that not only improve fuel efficiency but also reduce maintenance costs.

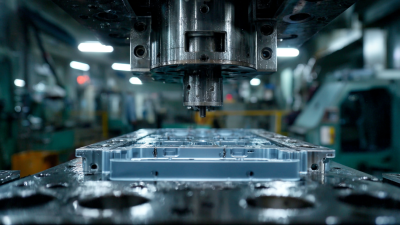

One of the key insights into the efficiency of injection molding in the marine industry is its ability to produce complex geometries with precision. A study published in the Journal of Marine Engineering & Technology highlights that components produced through injection molding can achieve tighter tolerances and superior surface finishes compared to traditional manufacturing methods. This precision reduces the need for secondary operations, reducing labor costs and production time. Additionally, with advancements in materials such as thermoplastics and composites, manufacturers can achieve substantial weight savings, enhancing the overall performance of marine vessels while complying with stringent environmental regulations.

Marine injection molding has emerged as a transformative process in the boat manufacturing industry, primarily due to its cost-saving advantages. By utilizing advanced injection molding techniques, manufacturers can produce high-quality components with significantly reduced material waste. This efficiency directly correlates with lower manufacturing expenses, as the precision of the process ensures that less polymer is needed to create each part. Consequently, companies can allocate their budgets more effectively, investing in other critical areas such as research and development or marketing.

Another significant aspect contributing to cost savings in marine injection molding is the speed of production. Traditional manufacturing methods often involve longer lead times, which can affect overall operational costs. In contrast, injection molding allows for rapid prototyping and mass production of components, enabling manufacturers to meet market demands more swiftly. This not only enhances productivity but also helps avoid delays that could lead to lost sales opportunities. By streamlining the production process, companies can maintain a competitive edge while improving their bottom line.

This chart illustrates the cost breakdown of various aspects involved in marine injection molding, showcasing the potential for cost savings and operational efficiency in the manufacturing process.

The choice of materials plays a pivotal role in the effectiveness of marine injection molding. Advanced resins, such as high-density polyethylene (HDPE) and polycarbonate, are engineered to withstand the harsh conditions found in marine environments. These materials offer exceptional resistance to corrosion, UV degradation, and impact, ensuring that marine components maintain their integrity and performance over time. Utilizing these advanced materials not only enhances durability but also contributes to a longer lifespan for marine products, reducing the need for frequent replacements.

Moreover, the right resins can significantly improve the efficiency of the production process itself. Advanced resins often feature excellent flow characteristics, allowing for quicker molding cycles and reduced energy consumption. This efficiency not only lowers production costs but also minimizes waste, making the manufacturing process more sustainable. By selecting high-performance resins tailored for marine applications, manufacturers can achieve superior results both in terms of product quality and environmental responsibility, ultimately leading to greater competitiveness in the marine industry.

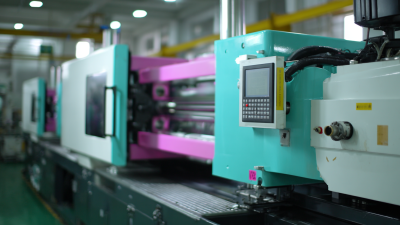

The marine industry is witnessing a remarkable transformation, driven by innovations in injection molding technologies. Recent reports indicate that the global marine injection molding market is projected to grow at a CAGR of 5.7% from 2023 to 2030, highlighting the increasing demand for efficient production methods. A key component of this growth is the advancement of machinery designed specifically for marine applications, incorporating features that enhance precision and reduce cycle times. For instance, the latest injection molding machines now utilize advanced materials and automation, allowing manufacturers to produce complex marine components with incredible speed and accuracy.

Moreover, the emergence of computer-aided design (CAD) software has revolutionized the designing process, enabling engineers to simulate and optimize mold designs before production. According to a study by the Marine Technology Society, using such innovations has reduced material waste by over 30% in marine manufacturing, leading to significant cost savings and a smaller environmental footprint. Coupled with eco-friendly polymers that are gaining traction in the industry, these advancements not only improve operational efficiency but also align with the industry's commitment to sustainability. As marine injection molding technology continues to evolve, companies that embrace these innovations are poised to gain a competitive edge in the rapidly changing marine sector.

Marine injection molding has emerged as a pivotal technology in enhancing efficiency while promoting sustainability in the maritime industry. This innovative manufacturing process not only allows for the precise creation of complex marine components but also prioritizes environmental benefits. By utilizing advanced materials that are often recyclable, marine injection molding minimizes waste and reduces the energy required in production processes.

One effective tip for companies looking to transition to marine injection molding is to conduct a thorough analysis of their existing materials and processes. Consider sustainable alternatives that align with injection molding capabilities, such as bioplastics or reclaimed materials. Additionally, implementing a closed-loop system can further decrease waste by reusing materials in the production cycle.

Finally, investing in energy-efficient machinery can significantly lower the carbon footprint of marine manufacturing operations. Opting for equipment that minimizes energy consumption not only enhances efficiency but also contributes to a greener marine industry. By embracing these practices, businesses can enjoy the dual benefits of improved performance and a commitment to sustainability in their operations.

| Dimension | Description | Benefits |

|---|---|---|

| Material Efficiency | Utilizes recyclable materials to minimize waste. | Reduces environmental footprint and material costs. |

| Energy Consumption | Low energy requirements during the molding process. | Decreases energy bills and lessens carbon emissions. |

| Production Speed | Faster production cycles compared to traditional methods. | Increases throughput, meeting market demands swiftly. |

| Customization | Easily customizable designs for specific marine applications. | Enhances product versatility and adaptation to customer needs. |

| Life Cycle Management | Facilitates management of product life cycles and end-of-life options. | Promotes sustainability and reduces waste in the marine sector. |