Plastic injection molding automotive is a powerful process that shapes the future of vehicle design. This manufacturing technique has transformed how parts are created and integrated. It offers a range of advantages that touch on efficiency, cost, and customization.

One key benefit is the ability to produce complex shapes with precision. This allows for innovative designs that meet modern standards. Parts can be made lighter and stronger, which is crucial in today’s automotive industry. Moreover, the speed of production reduces time-to-market, an essential factor for competitiveness.

However, the process is not without its challenges. Companies must navigate quality control and material selection carefully. Sometimes, unexpected flaws can arise. These require reflection and adjustment, pushing the industry toward continuous improvement. Overall, plastic injection molding automotive holds significant potential but also invites a need for ongoing evolution in practices.

Plastic injection molding is transforming automotive parts manufacturing. This technique offers remarkable advantages that the industry cannot ignore. For instance, production speed is significantly higher compared to traditional methods. According to a report by the Society of Automotive Engineers, injection molding can reduce cycle time by up to 50%. This efficiency directly impacts the manufacturing process, resulting in lower costs over time.

Another notable benefit is design flexibility. Designers can create complex shapes that were once impossible with metal. This opens up new possibilities for innovative designs. However, this flexibility can sometimes lead to challenges in production. Some complex designs may require meticulous adjustments to the molds. Additionally, the material selection is vital. While plastic offers weight reduction, it must be suitable for durability and safety. The right balance of weight and strength can be tricky.

Sustainability is also an important factor. More automotive manufacturers are investing in recycled plastics for injection molding. Some reports indicate that using recycled materials can reduce production emissions by 30%. While this is promising, not all recycled plastics meet the stringent safety requirements. The quest for eco-friendly options calls for continuous research and improvement. The industry must address these challenges to maximize the benefits of plastic injection molding.

| Benefit | Description | Impact on Cost | Impact on Production Time |

|---|---|---|---|

| High Precision | Molds can produce highly accurate and consistent parts. | Reduces rework and material waste, lowering costs. | Facilitates faster production cycles. |

| Design Flexibility | Allows for complex designs and integration of multiple components. | Can minimize assembly costs by combining parts. | Speeds up product development and market entry. |

| Material Efficiency | Enables the use of various polymers suitable for automotive applications. | Reduces the amount of raw material needed. | Shortens lead times with streamlined production processes. |

| Scalability | Efficiently produces large volumes of parts at a consistent quality. | Lower cost per item at scale. | Supports rapid scaling of production as demand increases. |

| Lightweight Components | Helps reduce the overall weight of vehicles, improving fuel efficiency. | Can lower energy costs and enhance vehicle performance. | Facilitates faster vehicle design and prototyping cycles. |

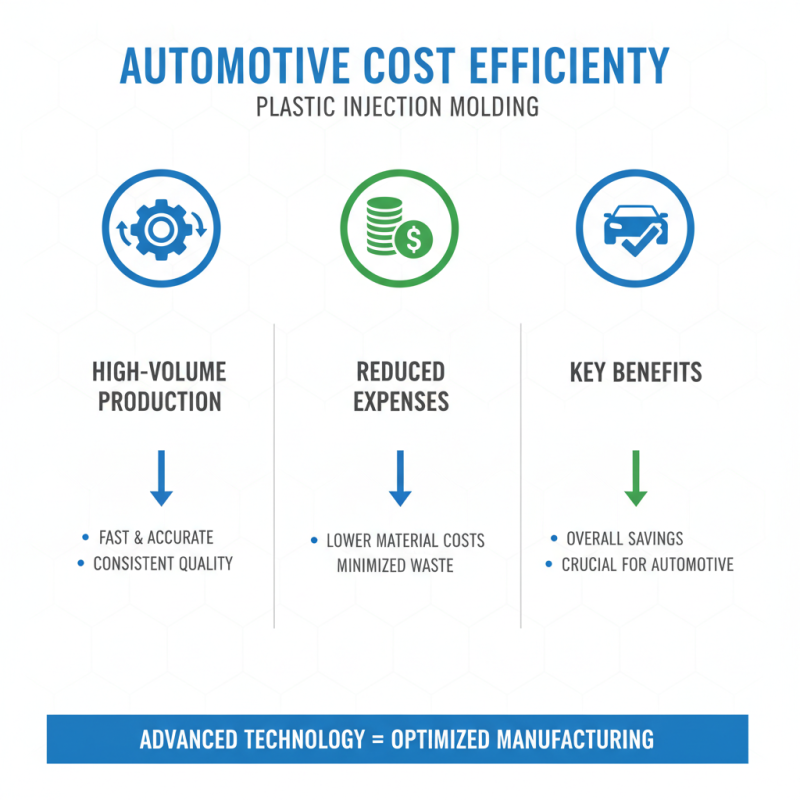

In the automotive industry, cost efficiency is crucial. Plastic injection molding significantly reduces expenses in high-volume production of automotive components. This method allows manufacturers to create parts quickly and accurately. The process uses advanced technology to ensure consistent quality, which minimizes waste. Lower material costs contribute to overall savings.

However, there are challenges. Not all designs work well with injection molding. Some intricate shapes may require additional adjustments. This can lead to higher development costs if revisions are needed. Additionally, the initial investment for molds can be substantial. Companies must carefully analyze whether the long-term savings justify these upfront costs.

Despite these considerations, the benefits can outweigh the drawbacks. High-speed production capabilities mean that large quantities of parts can be produced in a short time. This addresses the growing demand in the automotive market. As a result, businesses can meet customer needs more effectively while keeping expenses manageable. Finding the right balance is key for success in using this molding technique.

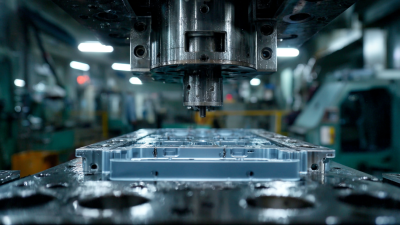

Plastic injection molding offers remarkable design flexibility for automotive plastic parts. This process allows manufacturers to create complex shapes with intricate details. Designs can incorporate multiple features in a single piece, reducing assembly time. Advanced tools help mold parts that fit together perfectly, minimizing gaps. Yet, challenges remain in achieving these standards consistently.

While the technology is efficient, not every design translates smoothly into production. Some complex features may lead to higher costs or production errors. Designers must balance creativity with practical limitations. The use of simulation software can aid in this regard, but it is not foolproof. Adjustments often are needed to ensure manufacturability, which may lead to design compromises.

The automotive industry continues to evolve, demanding innovative designs. As vehicles become smarter, the need for complex, integrated parts rises. However, the pursuit of sophistication must be paired with an understanding of manufacturing constraints. Continuous improvement in processes and materials remains essential for meeting these challenges. Ultimately, the flexibility of plastic injection molding can drive creativity but requires careful consideration and reflection on its limits.

Plastic injection molding is revolutionizing the automotive industry. One significant advantage is enhanced durability. Injection molded products can withstand harsh weather conditions. They resist impact and maintain their integrity over time. This quality is essential for automotive components that face daily stress.

Additionally, the performance of these products is notable. Injection molding allows for precision engineering. Components fit perfectly together, minimizing gaps and potential failures. This level of accuracy improves vehicle assembly and safety. However, quality control is crucial. Any lapse can lead to serious issues down the line.

Moreover, the versatility of materials used in injection molding expands possibilities. Manufacturers can select polymers based on required characteristics. From lightweight options to materials resistant to chemicals, this flexibility is beneficial. Yet, the continuous improvement of materials is necessary. Innovations will help address evolving challenges in the automotive sector.

Plastic injection molding has become a cornerstone in the automotive industry, especially concerning sustainability. This process allows manufacturers to create complex parts with minimal waste. Unlike traditional methods, injection molding uses only the necessary amount of material. This results in less scrap, making it an eco-friendlier choice.

However, it's essential to reflect on the long-term impacts of using plastics. While injection molding reduces material use, the environmental cost of plastic remains a concern. Many of these materials are not biodegradable. This paradox should prompt discussions about alternatives and innovations in materials. Additionally, recycling processes for these parts need improvement to enhance sustainability further.

Companies must also consider the energy consumed during the injection molding process. While it is efficient, the carbon footprint from energy sources can undermine benefits. Seeking renewable energy solutions may provide a path forward. A balanced approach is necessary to ensure that advancements in plastic molding align with true sustainability goals.

This chart illustrates the top five benefits of plastic injection molding in the automotive industry, focusing on their scoring based on factors like sustainability, cost efficiency, design flexibility, production speed, and durability.