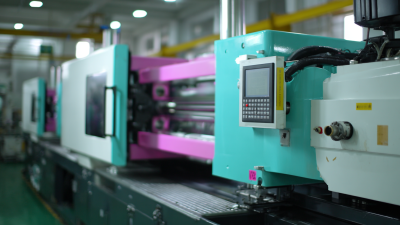

Plastic Injection Molding has emerged as a pivotal technology in modern manufacturing, revolutionizing how products are created across various industries. According to a report by MarketsandMarkets, the global plastic injection molding market is expected to reach $438.9 billion by 2025, driven by increasing demand for lightweight and high-performance materials. This manufacturing technique offers unparalleled advantages, including high production rates, precise dimensional accuracy, and the ability to produce complex geometries with minimal waste.

Plastic Injection Molding has emerged as a pivotal technology in modern manufacturing, revolutionizing how products are created across various industries. According to a report by MarketsandMarkets, the global plastic injection molding market is expected to reach $438.9 billion by 2025, driven by increasing demand for lightweight and high-performance materials. This manufacturing technique offers unparalleled advantages, including high production rates, precise dimensional accuracy, and the ability to produce complex geometries with minimal waste.

Furthermore, the versatility of plastic injection molding allows it to cater to diverse sectors such as automotive, consumer goods, and medical devices, enhancing its relevance in a competitive market landscape. Understanding the intricate process of plastic injection molding not only highlights its technical benefits but also underscores its crucial role in driving innovation and efficiency in manufacturing practices today.

Plastic injection molding is a highly efficient manufacturing process that transforms raw plastic materials into intricate and precise components. At its core, the process involves melting plastic pellets and injecting the molten material into a mold cavity, where it cools and solidifies into the desired shape.

This process is not only cost-effective for large-scale production runs but also enables manufacturers to create complex geometries with high levels of detail. Understanding the fundamentals of this technique is crucial for optimizing design and production efficiency, making it a cornerstone of modern manufacturing.

This process is not only cost-effective for large-scale production runs but also enables manufacturers to create complex geometries with high levels of detail. Understanding the fundamentals of this technique is crucial for optimizing design and production efficiency, making it a cornerstone of modern manufacturing.

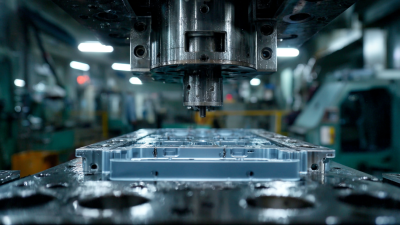

Key considerations in plastic injection molding include mold design, material selection, and process parameters. Mold design is critical as it determines the part's final quality and manufacturability. Selecting the appropriate plastic material impacts both the aesthetics and functionality of the end product, as different plastics offer varying properties like strength, flexibility, and thermal resistance. Moreover, controlling injection speed, temperature, and pressure during the molding process is essential to minimize defects and ensure consistent quality. By mastering these fundamentals, manufacturers can harness the full potential of plastic injection molding to innovate and meet the evolving demands of the marketplace.

Injection molding is becoming increasingly crucial in modern manufacturing, driven by its ability to produce complex shapes efficiently and cost-effectively. The injection molding market is projected to grow significantly, with an estimated value of USD 365.22 billion in 2024, expanding to USD 580.44 billion by 2033 at a CAGR of 4.74%. This robust growth underscores the process's importance for manufacturers looking to enhance productivity while managing costs.

One of the key benefits of incorporating injection molding into manufacturing is its adaptability to the production of lightweight composite structures. As advanced manufacturing technologies evolve, injection molding allows for seamless integration of innovative materials, optimizing the performance of end products. Moreover, the use of smart manufacturing technologies in injection molding facilitates real-time data analysis and machine learning, which improves the precision and efficiency of production processes, ultimately yielding higher-quality products. This collective shift towards smart manufacturing signifies a transformative era that enhances operational capabilities and empowers manufacturers to meet the growing demand for customized and high-performance components.

Injection molding stands out among various manufacturing techniques due to its efficiency and precision in producing intricate designs. Unlike traditional methods such as machining or casting, injection molding allows for high-volume production with minimal waste. This process utilizes a heated barrel to melt plastic pellets, which are then injected into a mold. The ability to quickly create complex shapes makes injection molding preferable for producing components in industries ranging from automotive to consumer electronics. Furthermore, the final products often require little to no finishing, enhancing overall productivity.

In contrast to methods like blow molding or 3D printing, injection molding offers superior consistency and repeatability. While blow molding is effective for hollow objects, its complexity increases with design intricacies. On the other hand, 3D printing, while versatile, is typically slower for mass production and may incur higher per-unit costs. Therefore, for manufacturers aiming for high efficiency and low cost-per-unit, injection molding emerges as the preferred choice, merging speed with high-quality output, making it a cornerstone of modern manufacturing strategies.

Plastic injection molding is a crucial manufacturing process widely utilized across various industries due to its efficiency and versatility. One of the most common applications can be found in the automotive sector, where lightweight plastic components are essential for improving fuel efficiency and reducing manufacturing costs. Items such as dashboards, bumpers, and interior trim pieces are often produced using injection molding, allowing for precise designs and high-quality finishes that meet stringent safety standards.

In the consumer goods sector, plastic injection molding is pivotal in creating everyday items ranging from kitchenware to electronic casings. This process facilitates the rapid production of complex shapes and designs, providing businesses with the agility to respond to market demands effectively. Moreover, in the medical industry, injection molding produces critical components such as syringes, surgical instruments, and housings for medical devices, ensuring high hygiene standards and reliability. The adaptability of injection molding to different materials enhances its application across sectors, making it a foundational technique in modern manufacturing.

The landscape of plastic injection molding is continually evolving, driven by innovations that significantly enhance manufacturing processes. According to a report by MarketsandMarkets, the global injection molding market is projected to reach $337.4 billion by 2026, growing at a CAGR of 4.7% from 2021. This growth is fueled by advancements in technology, such as the integration of automation and smart manufacturing practices. Automated systems reduce cycle times and enhance precision, resulting in higher productivity and reduced waste.

Moreover, breakthroughs in materials science are also shaping the future of injection molding. The development of bio-based and recycled plastics is becoming increasingly prevalent, addressing the environmental concerns associated with traditional polymers. For instance, a study by the American Chemistry Council indicates that using recycled plastic in injection molding can reduce energy consumption by up to 88%. As the demand for sustainable practices increases, manufacturers who embrace these innovations will not only benefit from operational efficiencies but will also gain a competitive edge in a market that values eco-friendly solutions.