In the rapidly evolving automotive industry, the importance of selecting the right Automotive Plastic Injection Molding Companies cannot be overstated. According to a recent report by MarketsandMarkets, the global automotive plastic market is projected to grow from $27.2 billion in 2021 to $37.9 billion by 2026, highlighting the increasing reliance on plastic components for vehicle manufacturing. This growth is driven by the rising demand for lightweight materials to enhance fuel efficiency, as well as the push for sustainable manufacturing practices.

However, with numerous companies offering various capabilities and specializations, finding one that aligns with your specific needs can be a daunting task. This blog will provide essential tips and insights to help you navigate this critical decision-making process and ensure you partner with a company that can deliver high-quality, cost-effective solutions tailored to your automotive projects.

When choosing an automotive plastic injection molding company, it is crucial to first identify your specific needs within the industry. Automotive applications often require high-quality, durable parts that can withstand various environmental factors. Whether you need components for interior fittings, exterior panels, or complex assemblies, understanding the specific thermoplastic materials suited for each application will guide you in selecting a provider that specializes in those areas. By clearly defining these requirements, including tolerance levels and production volumes, you can streamline your search for potential molding solutions.

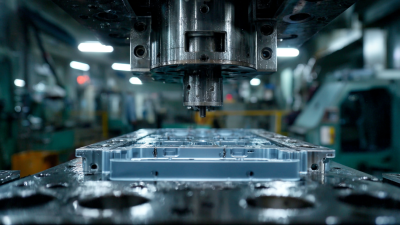

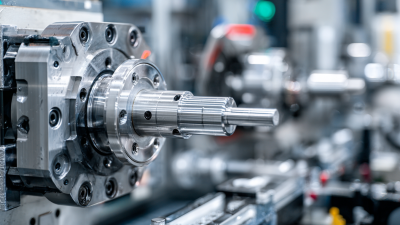

Another significant factor to consider is the technological capabilities of the molding company. With the plastic injection molding machine market experiencing substantial growth, it is essential to partner with a company that invests in modern equipment capable of meeting your production demands efficiently. Look for companies that leverage advanced technology, such as optimized storage solutions for injection tooling, to enhance their operational effectiveness. This will not only improve production efficiency but also ensure that the quality of the molded parts meets the automotive industry’s stringent standards.

When selecting an automotive plastic injection molding company, evaluating their experience in the industry is paramount. An established company typically brings a wealth of knowledge, specialized skills, and a deeper understanding of the intricacies involved in automotive parts manufacturing. You should inquire about their previous projects, the types of materials they have worked with, and their familiarity with the specific requirements of the automotive sector. A strong track record in producing high-quality, durable parts can indicate a company’s ability to meet the rigorous standards of automotive applications.

Moreover, it’s essential to consider the company’s technical capabilities and certifications. Look for manufacturers that are ISO certified or have relevant industry certifications, as these can be markers of a commitment to quality and safety. Additionally, assess their proficiency in utilizing advanced technologies and techniques in the injection molding process. Companies that invest in the latest equipment and stay updated on industry trends will likely provide more innovative solutions and improved turnaround times, ensuring your automotive components are not just reliable but also ready for the challenges of modern vehicles.

When selecting the right automotive plastic injection molding company, understanding the technology and equipment utilized is paramount for ensuring quality and efficiency in production. The injection molding process requires sophisticated machinery capable of producing complex parts with high precision. According to the report by MarketsandMarkets, the global injection molding machine market is projected to grow from $13.7 billion in 2020 to $17.9 billion by 2025, indicating a significant investment in technology within the industry.

Advanced technologies, such as multi-component injection molding and additive manufacturing, have become increasingly prevalent. These methods allow for reduced cycle times and improved part performance, essential factors in the automotive sector where rapid innovation and cost-effectiveness are crucial. Utilizing high-quality, automated machinery can increase production rates and minimize defects, with studies showing that automation can lead to efficiency improvements of up to 30%. By prioritizing companies that leverage these advanced systems, automotive manufacturers can ensure they receive components that meet the industry's stringent standards while maintaining competitive edge.

When selecting an automotive plastic injection molding company, a critical factor to consider is their quality assurance practices and certifications. According to the International Organization for Standardization (ISO), companies with ISO 9001 certification have documented processes to ensure product quality and minimize defects, which is vital in the automotive sector. Reports indicate that companies adhering to these standards can reduce production defects by 20-30%, leading to increased customer satisfaction and lower warranty claims.

Tip: Always inquire about the certifications held by the injection molding company, such as ISO 9001 or IATF 16949. These certifications indicate a commitment to quality and continuous improvement in processes.

In addition to certifications, examining the company’s quality assurance practices can shed light on their manufacturing capabilities. A recent survey by Plastics Technology revealed that 78% of leading automotive manufacturers prioritize suppliers who implement stringent quality controls throughout the production process. This includes methods like process monitoring, regular audits, and compliance with industry-specific regulations.

Tip: Request detailed information on the company’s quality control procedures and how they monitor production processes to ensure consistency and reliability in their products.

When selecting an automotive plastic injection molding company, it's essential to consider not only the costs but also the production timelines that different manufacturers offer. Cost efficiency is paramount, especially when comparing manufacturers in varied geographical locations. For instance, some regions may present lower labor costs, yet evaluating the quality and reliability of the manufacturer can ultimately influence your overall expenditure in the long run.

Tips: Focus on manufacturers that provide transparent pricing structures and clear timelines. Ensure that they align with your production schedule to avoid costly delays. Additionally, consider their experience and expertise in specific automotive applications, as this can significantly impact the quality and durability of the parts produced.

Another aspect to compare is the technological capability of the manufacturers. As markets evolve, companies with advanced technology can produce better quality products while maintaining competitive prices. Understanding a manufacturer's technique in cost reduction when technology becomes widespread is crucial for making an informed choice and establishing a long-term partnership.

Tips: Research manufacturers’ technological advancements and ask for case studies or examples of previous projects. This will ensure that you choose a partner capable of meeting both your immediate and future needs in the automotive industry.