Injection molding has become a pivotal process in the automotive industry, enabling manufacturers to produce high-quality plastic components with precision and efficiency. As the demand for lightweight, durable, and complex parts continues to rise, mastering the art of injection molding automotive applications is essential for companies aiming to maintain a competitive edge. This article explores ten essential tips for successful injection molding specifically tailored for the automotive sector, ensuring that producers can refine their processes while adhering to industry standards.

The automotive industry faces unique challenges, including stringent regulations, tight production timelines, and the need for cost-effective solutions. Understanding the intricacies of injection molding automotive applications can help manufacturers overcome these hurdles. From material selection to mold design, each element plays a crucial role in producing reliable and high-performance components. By implementing best practices, companies can not only enhance their product quality but also optimize production efficiency and reduce waste.

In this guide, we will delve into key strategies that can drive success in injection molding within the automotive context. Whether you are a seasoned expert or new to the field, these tips will provide valuable insights into achieving excellence in automotive component production, ultimately contributing to the development of innovative and sustainable vehicles.

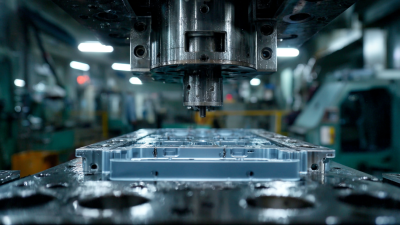

Injection molding is a critical manufacturing process in the automotive industry, widely utilized for producing complex components with high precision and repeatability. Understanding the basics of this technique is essential for engineers and manufacturers looking to leverage its benefits. At its core, injection molding involves melting plastic granules and injecting them into a mold to create specific shapes.

This method allows for the efficient production of parts such as dashboard components, housings, and various internal mechanisms that contribute to vehicle functionality and aesthetics.

To ensure success in automotive applications, it is crucial to consider material selection, mold design, and process parameters carefully. Different automotive parts may require specific plastic materials with distinct properties, like high durability or resistance to heat and chemicals. Moreover, mold design must accommodate the intricacies of automotive components while ensuring easy part ejection and consistent wall thickness.

By optimizing injection speed, temperature, and cooling time, manufacturers can achieve high-quality parts that meet stringent industry standards, reduce waste, and enhance overall production efficiency in the highly competitive automotive market.

Material selection is a critical factor in the success of injection molding in the automotive industry. With the market for automotive plastics projected to reach approximately $42 billion by 2025, choosing the right materials is more vital than ever. According to a report by the Plastics Industry Association, materials like polypropylene and polycarbonate are increasingly favored due to their lightweight properties and excellent rigidity, which contribute to improved fuel efficiency and enhanced vehicle performance. The right material not only ensures durability but also meets stringent safety regulations and environmental standards.

In addition to performance characteristics, cost-effectiveness also plays a significant role in material selection. Researchers estimate that polymer composites can reduce the overall weight of automotive components by up to 30%, leading to substantial fuel savings over a vehicle's lifetime. Furthermore, advancements in additive manufacturing and recycling technologies are enabling manufacturers to explore innovative materials that significantly reduce waste and promote sustainability. Thus, careful consideration of material properties, environmental impact, and cost will ultimately drive better outcomes in the highly competitive automotive sector.

| Tip Number | Consideration | Material Type | Recommended Properties | Application |

|---|---|---|---|---|

| 1 | Choose the Right Polymer | PP (Polypropylene) | High impact resistance, lightweight | Interior components |

| 2 | Evaluate Thermal Stability | PA (Nylon) | High heat resistance, good dimensional stability | Engine components |

| 3 | Assess Chemical Resistance | POM (Polyoxymethylene) | Excellent chemical resistance, low friction | Fuel system parts |

| 4 | Consider Weight | ABS (Acrylonitrile Butadiene Styrene) | Lightweight, good rigidity | Body panels |

| 5 | Focus on Surface Finish | PC (Polycarbonate) | Optical clarity, excellent impact resistance | Lighting components |

Optimizing mold design is crucial for enhancing both performance and efficiency in the automotive injection molding process. According to a report from the Society of Plastics Engineers, more than 70% of defects in molded parts can be traced back to inadequate mold design. This underscores the importance of strategic planning in the initial stages of mold development.

Utilizing simulation software allows for better prediction of part behavior during production, which helps mitigate issues such as warping and shrinkage. These advanced tools can also reduce cycle times by up to 20%, significantly enhancing productivity.

The choice of materials used in mold construction further affects the longevity and efficiency of injection molds. A study by the American Injection Molding Institute highlights that employing high-grade steel and advanced surface treatments can increase mold life expectancy by over 30%. Additionally, incorporating conformal cooling channels into the mold design can lead to a more uniform temperature distribution, reducing cooling time and enhancing the overall cycle efficiency.

These design enhancements not only promote better part quality but also contribute to cost savings through minimized downtime and reduced scrap rates in the automotive manufacturing process.

Quality control is a critical aspect of the injection molding process in the automotive industry. To maintain the highest standards, manufacturers must implement rigorous inspection protocols at every stage. This includes reviewing material specifications before production begins, ensuring that raw materials meet the necessary performance and safety criteria. Regular checks during the molding process can help identify any deviations from desired parameters, allowing for immediate corrective actions to prevent defects.

Moreover, utilizing advanced technologies such as in-line measurement systems can greatly enhance quality assurance. These systems can monitor critical dimensions and tolerances in real time, providing instant feedback and alerting operators to any irregularities. Investing in employee training also plays a vital role; well-informed staff can recognize potential issues early, fostering a culture of quality. By prioritizing quality control throughout the injection molding process, automotive manufacturers can minimize waste, reduce recalls, and ultimately enhance the overall reliability of their products.

This chart illustrates key quality control metrics for successful injection molding in the automotive industry, helping identify areas for improvement and ensuring product reliability.

Injection molding is a critical process in the automotive industry, but various challenges can arise during production. One common issue is inconsistent part quality, which can be addressed by regularly checking and calibrating the injection molding machines. Ensuring that the material is properly dried before processing is another essential step. Moisture can lead to defects such as bubbles and surface imperfections, negatively impacting the final product.

Another prevalent challenge is mold wear and tear, which can cause dimensional inaccuracies in parts. To combat this, it’s crucial to establish a routine maintenance schedule for molds, including cleaning and inspection. Additionally, incorporating advanced cooling systems can help prolong mold life and enhance the quality of the final products. It’s also advisable to optimize cycle times, improving efficiency while maintaining quality, enabling quicker troubleshooting of potential issues.

Finally, monitoring processing parameters such as melt temperature and injection speed plays a pivotal role in minimizing defects. By closely tracking these variables, manufacturers can swiftly identify deviations from the norm and implement corrective actions. Emphasizing these best practices helps to troubleshoot common injection molding issues effectively, ensuring successful production in the competitive automotive landscape.