Golf Cart Plastic Injection Molding has become an essential process in the manufacturing of durable and lightweight components for golf carts. This technique allows for the creation of intricately designed parts that cater specifically to the unique needs of the golf cart industry. As John Smith, a leading expert in plastic manufacturing, once said, “The precision and efficiency of Golf Cart Plastic Injection Molding are unparalleled, making it the preferred method for crafting high-quality golf cart components.”

Golf Cart Plastic Injection Molding has become an essential process in the manufacturing of durable and lightweight components for golf carts. This technique allows for the creation of intricately designed parts that cater specifically to the unique needs of the golf cart industry. As John Smith, a leading expert in plastic manufacturing, once said, “The precision and efficiency of Golf Cart Plastic Injection Molding are unparalleled, making it the preferred method for crafting high-quality golf cart components.”

The benefits of this innovative molding process are manifold, ranging from enhanced production speeds to the ability to utilize a variety of plastic materials that can withstand weathering and frequent use. Golf manufacturers are increasingly turning to Golf Cart Plastic Injection Molding not only for its cost-effectiveness but also for its capacity to produce parts with consistent quality and intricate details that elevate the overall design of the carts.

Moreover, the applications of this molding technique extend beyond just golf carts; it is also applicable in producing various accessories and aftermarket modifications that enhance the golfing experience. As the industry continues to grow, the significance of Golf Cart Plastic Injection Molding will only increase, solidifying its role in shaping the future of golf cart manufacturing.

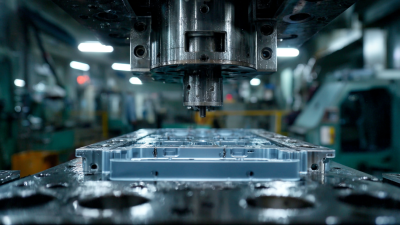

Golf cart plastic injection molding is a specialized manufacturing process that involves shaping molten plastic into precise components used in golf carts. The process begins with heating plastic pellets until they melt, after which the liquid plastic is injected into a mold that defines the desired shape of the part. This method allows for high levels of accuracy and repeatability, making it ideal for producing parts such as dashboards, seats, and body panels. The versatility of injection molding also enables manufacturers to use a variety of materials, including thermoplastics, which can be recycled and reused, contributing to sustainability in production.

In addition to efficiency and sustainability, golf cart plastic injection molding offers several key benefits. One of the primary advantages is the ability to create complex shapes and designs that would be difficult or impossible to achieve with other manufacturing techniques. The process also minimizes waste, as any excess plastic can often be reused in future production runs. Furthermore, the consistency of the injection molding process ensures that each part meets stringent quality standards, which is crucial in the competitive golf cart market. This technology not only enhances the aesthetic appeal of golf carts but also improves their overall durability and performance.

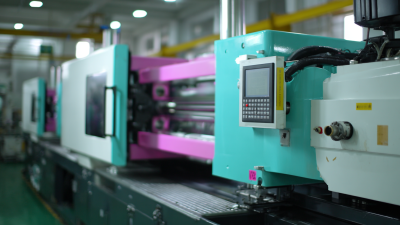

Plastic injection molding has become an essential process in the production of golf carts, offering several key benefits that enhance both manufacturing efficiency and product performance. This technique allows for the creation of complex shapes and features that are lightweight yet durable, crucial for the demands of outdoor environments. Using plastic components can significantly reduce overall weight, improving the efficiency of the golf carts while enhancing their speed and maneuverability.

**Tip:** Consider materials like high-density polyethylene (HDPE) for parts that require excellent UV resistance and impact strength, essential for outdoor usage.

Furthermore, the customization capabilities of plastic injection molding enable manufacturers to design bespoke components that meet specific customer needs, from aesthetic modifications to functional enhancements. This flexibility not only reduces the time and cost associated with traditional manufacturing methods but also supports rapid prototyping for new designs. Innovations in molding technologies, including the integration of robotics, further streamline production processes, ensuring consistent quality and precision.

**Tip:** Embrace automation in the injection molding process to boost production efficiency and maintain high standards of quality control.

Golf cart plastic parts play a crucial role in various applications within the automotive and recreational industries. These components are vital for enhancing the performance, safety, and aesthetic appeal of golf carts. For example, durable plastic parts such as dashboards, seats, and body panels are engineered to withstand the elements, ensuring longevity and resilience. Their lightweight nature not only contributes to the overall efficiency and handling of the cart but also improves fuel economy, making them an ideal choice for electric models.

Moreover, in the recreational sector, plastic parts are increasingly favored for customizability and design flexibility. Manufacturers can easily create components that meet specific design requirements, allowing for vibrant colors and unique styles that appeal to different consumer preferences. This innovation provides an opportunity to personalize golf carts, increasing their marketability among enthusiasts. As a result, golf carts equipped with high-quality plastic parts are not only functional but also cater to the growing demand for stylish and individualized vehicles in recreational settings.

The golf cart manufacturing industry has been experiencing significant growth, driven largely by the increasing demand for leisure activities and eco-friendly transportation solutions. According to a report by Grand View Research, the global golf cart market size was valued at approximately $1.4 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of around 5.5% from 2023 to 2030. This upward trend highlights the rising popularity of golf carts not only in golf courses but also in residential communities and commercial applications.

Factors contributing to this growth include the growing awareness of the environmental impact of traditional vehicles, leading consumers and businesses alike to adopt more sustainable options. Additionally, advancements in electric golf cart technology have made these vehicles more efficient and accessible. The demand for custom components, enabled by innovations in golf cart plastic injection molding, has further catalyzed market expansion. As evidenced by a report from Mordor Intelligence, the application of plastic injection molding in manufacturing has increased the production efficiency and product customization capabilities, enhancing overall market competitiveness.

Sustainability in golf cart production is becoming increasingly important, as manufacturers seek eco-friendly materials and practices in their injection molding processes. According to a report by the Grand View Research, the global automotive plastics market is anticipated to reach $42.2 billion by 2025, with sustainability being a driving force for innovation. Golf cart producers are now leveraging biodegradable and recyclable plastics to reduce their environmental footprint. These materials not only help in minimizing waste but also contribute to a circular economy where components are repurposed or recycled at the end of their life cycle.

Furthermore, the adoption of sustainable practices in injection molding, such as energy-efficient machinery and waste reduction techniques, can significantly lower carbon emissions associated with production. Data from the American Chemistry Council indicates that using recycled plastics can reduce the energy consumption required for manufacturing by up to 80%. As golf cart manufacturers continue to prioritize eco-friendly materials, they not only enhance their brand reputation but also align with growing consumer demand for sustainability, ensuring their products are both high-performing and environmentally responsible.