In today's competitive manufacturing landscape, mastering Plastic Injection Molding is essential for businesses aiming for success and innovation. This versatile production process allows for the efficient creation of complex parts with high precision, making it a cornerstone of modern manufacturing.

However, navigating the intricacies of Plastic Injection Molding can be daunting, especially for those new to the industry. In this ultimate guide, we will explore the fundamental principles behind this technique, provide actionable tips to enhance your production process, and share best practices to help you streamline operations.

Whether you're a seasoned manufacturer or a newcomer looking to invest in this technology, understanding the nuances of Plastic Injection Molding will empower you to optimize your processes, reduce costs, and ultimately elevate your business to new heights.

Join us as we delve into the essential strategies that will set your enterprise on the path to manufacturing excellence.

Understanding the basics of plastic injection molding is essential for businesses looking to excel in the manufacturing sector. This process involves injecting molten plastic into a mold to create a variety of products, which can range from simple components to complex assemblies. As the global market for plastic injection molding is projected to grow significantly in the coming years, it's crucial for businesses to grasp the fundamentals of this technology to remain competitive.

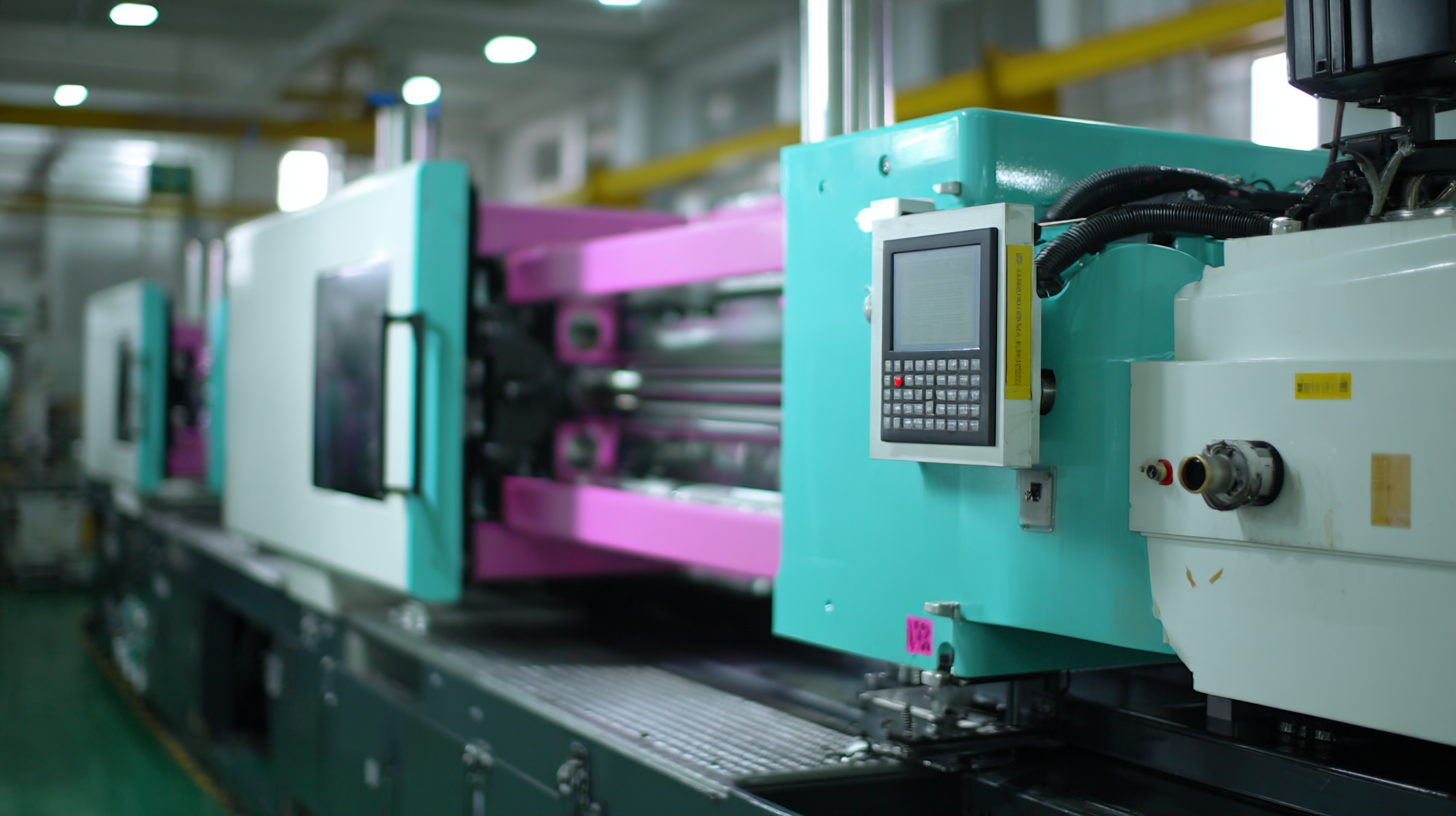

One key tip for mastering plastic injection molding is to invest in quality machinery. Reliable and advanced equipment can enhance efficiency, reduce waste, and ensure consistent product quality. Another vital aspect is the importance of choosing the right materials. Understanding the properties and applications of different plastics can greatly influence the performance and durability of the final product.

Additionally, maintaining a strong focus on sustainability is increasingly becoming a priority in the industry. Companies should consider integrating recycling practices and exploring innovative ways to minimize their environmental impact while optimizing production processes. By establishing a solid foundation in these areas, businesses can position themselves for long-term success in the dynamic world of plastic injection molding.

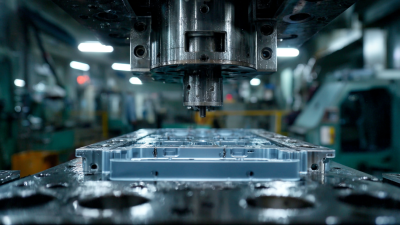

When it comes to mastering plastic injection molding, understanding the key equipment and technology involved in the process is crucial for achieving efficiency and excellence. At the heart of this operation are injection molding machines, which come in various types, including hydraulic, electric, and hybrid options. Hydraulic machines are known for their power and speed, making them ideal for large-scale production runs involving complex shapes. Meanwhile, electric machines offer precision and energy efficiency, allowing for tighter tolerances and more intricate designs. The choice of machine ultimately impacts not only the quality of the finished product but also the operational costs.

In addition to the machines themselves, the technology used in plastic injection molding plays a vital role in streamlining processes. Advanced software systems enable simulation of the molding process, helping manufacturers anticipate potential issues before production begins. Furthermore, incorporating automation technologies, such as robotic arms for part removal and packaging, enhances productivity and reduces labor costs. By integrating these tools and technologies, businesses can optimize their injection molding processes, leading to improved product quality, faster turnaround times, and ultimately a greater competitive edge in the marketplace.

Designing parts for injection molding is a critical step that can significantly impact the success of plastic products in various industries. According to a report by Grand View Research, the global injection molding market is projected to reach $441.4 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.4%. This growth underscores the importance of well-designed components that meet market demand effectively.

A successful injection molding design process involves several key considerations: material selection, wall thickness, and moldability. For instance, using materials with the right mechanical properties can enhance durability while optimizing the part's weight. The American Society of Mechanical Engineers (ASME) suggests that maintaining a wall thickness between 1.5mm and 3mm typically ensures better flow and reduces defects. Additionally, features such as draft angles should be incorporated into the design to facilitate easy ejection from molds, which can decrease cycle times and production costs.

Furthermore, simulation tools like Moldflow can provide insights into potential molding issues before production begins, saving both time and resources. By leveraging these advanced design strategies and industry insights, businesses can create high-quality parts that not only meet stringent specifications but also anticipate consumer needs in a rapidly evolving market.

Quality control is paramount in the plastic injection molding process to ensure that the final products meet the highest industry standards. The process begins with selecting the right materials and optimizing the injection molding machine's key units, including the clamping device, plasticizing device, and drive unit. Each component plays a critical role in achieving precision and consistency. For instance, the clamping system must securely hold the mold in place, preventing any misalignment during injection, which could lead to defects.

Once the machine is set up, implementing strict quality control measures is essential. This can involve routine inspections of the molded products, assessing dimensions against specifications, and testing for material integrity. Utilizing advanced polymer formulations can enhance the durability and performance of the final products. Manufacturers should invest in technology and training to ensure that their teams are well-equipped to identify and rectify issues early in the production process. By maintaining rigorous quality control standards, businesses can achieve not only compliance but also customer satisfaction, ultimately driving their success in the competitive market.

| Parameter | Recommended Level | Actual Level | Remarks |

|---|---|---|---|

| Cycle Time | 30 seconds | 32 seconds | Minor delays observed |

| Temperature Control | 220°C | 225°C | Monitor heating elements |

| Pressure Level | 1200 psi | 1150 psi | Adjust pump settings |

| Material Viscosity | 700-800 cP | 750 cP | Within required range |

| Defect Rate | < 2% | 1.8% | Satisfactory |

Optimizing injection molding operations can significantly enhance your business's cost-effectiveness and overall success. Research indicates that advanced machine learning models can streamline processes by predicting and identifying potential defects in molded parts, which directly reduces waste and improves operational efficiency. For instance, a review highlighted that implementing artificial neural networks in injection molding can lead to a considerable decrease in production costs while maintaining high product quality.

**Tips for Optimization:** Monitor your operational conditions closely. Adjusting parameters such as temperature and pressure can minimize defects, as demonstrated in studies where variations led to notable improvements in product integrity. Additionally, consider optimizing mold design to include efficient cooling channels. A comparative analysis revealed that innovative cooling solutions could reduce cycle times by up to 20%, further enhancing productivity.

Investing in digital twin technology offers another avenue for optimization. By simulating the manufacturing process, companies can anticipate challenges and adjust strategies in real-time. This proactive approach not only saves costs but also fosters continuous improvement, ensuring your injection molding operations remain competitive in a rapidly evolving industry.