Unlocking Efficiency and Quality with Multi-Shot Plastic Injection Molding

In the world of manufacturing, innovation is the key to staying ahead of the competition. One such innovation that has revolutionized the Injection Molding process is multi-shot plastic injection molding. This advanced technology involves using multiple injection points or units to fill the mold cavity, resulting in improved efficiency and product quality, especially for complex products with multiple characteristics.

The importance of temperature control in injection molding

Injection molding is a widely used manufacturing process in which molten material is injected into a mold to form a desired shape as it cools and solidifies. This process is utilized in various industries to produce a wide range of products, from automotive components to consumer goods. However, the success of injection molding heavily relies on the precise control of temperature throughout the process. In this blog, we will delve into the importance of temperature control in injection molding, exploring its impact on product quality, molding efficiency, cost control, surface appearance, production cycle time, and material properties.

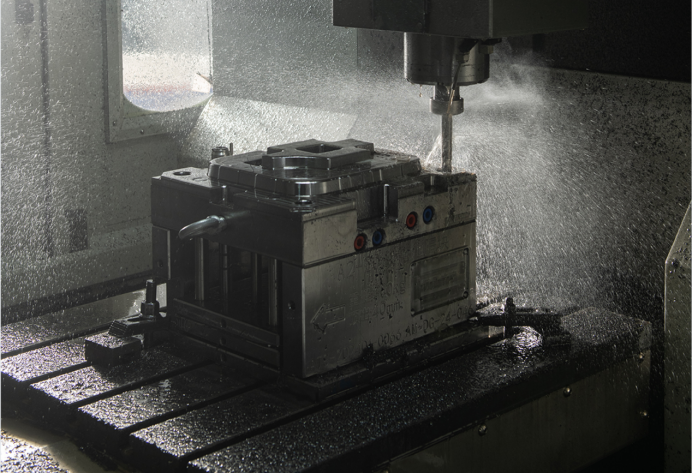

Overcoming the Challenges of Precision Injection Molding

Precision injection molding is a critical manufacturing process that plays a pivotal role in producing high-quality plastic products with intricate designs and tight tolerances. However, this advanced manufacturing technique comes with its own set of challenges that require careful consideration and expertise to overcome. From material selection and mold design to heat control and high-precision manufacturing, the difficulties of precision injection molding demand innovative solutions and meticulous attention to detail.

What are the Benefits of Plastic Injection Molding?

Plastic injection molding has revolutionized the manufacturing industry, offering a wide range of benefits that make it a preferred choice for producing high-quality, precise, and cost-effective plastic parts.

Causes and Solutions for Injection Molding Warpage

Injection molding warpage is a common issue that can seriously affect the quality and functionality of molded parts.

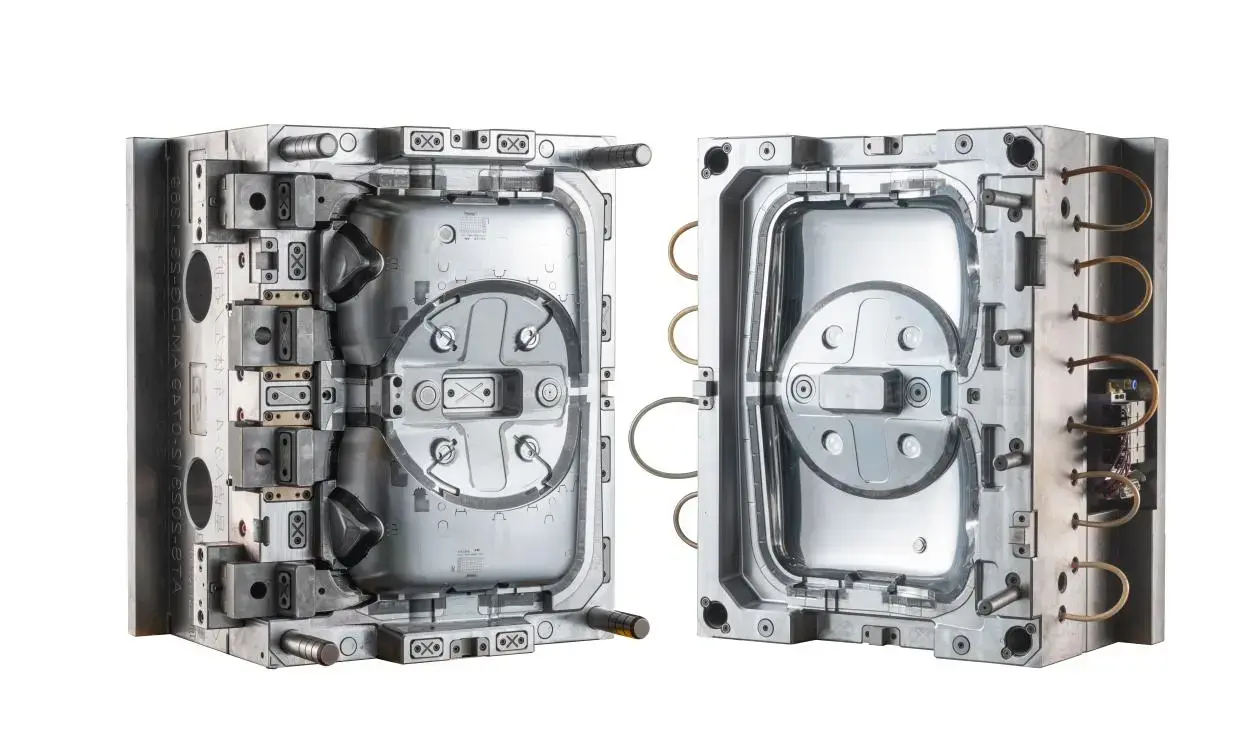

How to Choose the Right Mold Material for Your Product

When it comes to selecting the right mold material for your product, there are multiple factors that need to be carefully considered.

Effective Mold Maintenance Tips to Extend Service Life

Mold maintenance is a critical aspect to ensure the longevity and performance of Injection Molds.

The Impact of Mold Material on Product Durability

In the world of manufacturing, the choice of mold material plays a crucial role in determining the durability and quality of the final product.