Ensuring High-Quality Mold Manufacturing: Key Processes and Considerations

Mold manufacturing is a critical aspect of the production process for various industries, including automotive, consumer goods, and electronics. The quality of molds directly impacts the final product's performance, durability, and overall production efficiency. To achieve high-Quality Mold manufacturing, several key processes and considerations must be carefully addressed. In this article, we will delve into the essential processes that have the greatest impact on mold quality during manufacturing.

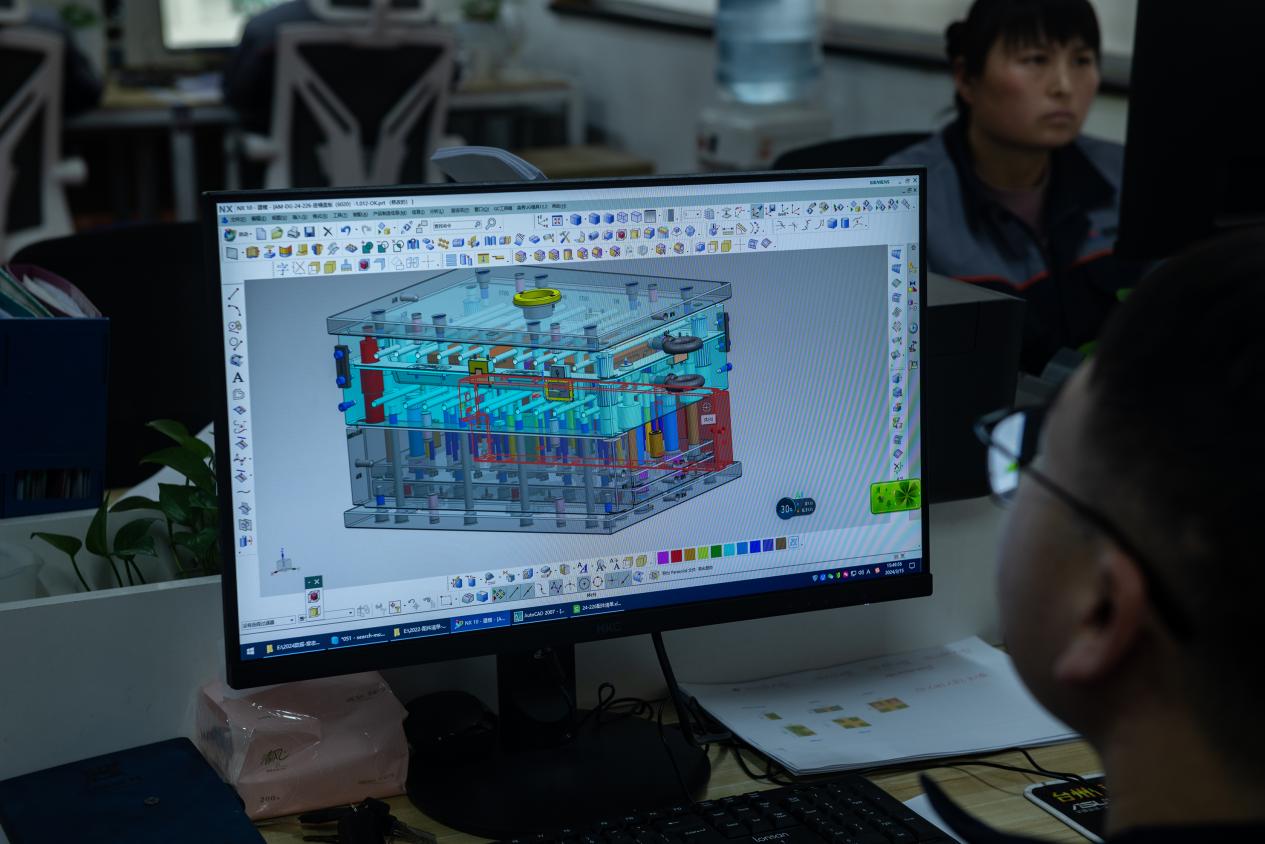

Mold Design: The Foundation of Quality Control

The mold design phase is a pivotal link to ensure mold quality. Designers must meticulously consider the size, shape, and structural requirements of the product. Additionally, they need to make informed decisions regarding the material, structure, and processing technology of the mold. The quality of the design directly influences the functionality and production efficiency of the mold. A well-thought-out design can lead to enhanced mold performance and longevity.

Material Selection: Impacting Hardness and Wear Resistance

The choice of mold material significantly affects the quality of the mold. Selecting suitable materials can improve the hardness, wear resistance, and corrosion resistance of the mold, thereby improving its service life and processing accuracy. Different plastics require different types of steel, depending on specific requirements such as high polishing or corrosion resistance. The right material selection is crucial for achieving optimal mold quality.

Processing Technology Control: Precision and Accuracy

The processing technology of the mold plays a pivotal role in determining its quality. During the processing phase, it is essential to control processing accuracy, technology, and the selection of processing equipment. This includes ensuring dimensional accuracy, shape accuracy, and surface accuracy. Precision in processing technology is the key to achieve high-quality molds.

Heat Treatment: Enhancing Surface Hardness and Longevity

Surface treatment of the mold is equally important. Processes such as nitriding can enhance the surface hardness of steel, effectively extending the mold's lifespan. Electroplating is another key method that can modify the mold steel, particularly for plastic parts requiring high brightness and corrosion resistance. Proper heat treatment is essential for strengthening and improving the properties of the mold steel.

Structural Design: Considering Material Properties and Cooling

A mature mold structure takes into account various factors such as product material properties, shrinkage, molding temperature, and elastic tensile deformation coefficient. Additionally, it considers the cooling water channel, mold opening and closing speed, among other aspects. A well-considered mold structure can effectively extend the mold's lifespan, ensure smooth production, improve efficiency, and reduce costs.

Mold Processing: Ensuring Accuracy and Quality

The arrangement of mold technology is of paramount importance. Proper mold processing is crucial for ensuring the accuracy and quality of the mold. Each step in the processing phase must be meticulously executed to achieve high-quality molds.

Inspection and Testing: Ensuring Mold Quality

After mold manufacturing, thorough inspection and testing are essential steps to guarantee mold quality. Through meticulous testing, manufacturers can gain insights into the mold's performance during the production process and assess the structural integrity of the plastic parts. This step is essential for identifying any potential issues and ensuring the overall quality of the mold.

In conclusion, the processes and considerations outlined above collectively determine the final quality and performance of the mold. Therefore, strict control and attention to detail during each of these key steps are imperative during the mold manufacturing process. By prioritizing mold design, material selection, processing technology control, heat treatment, structural design, mold processing, and inspection and testing, manufacturers can ensure the production of high-quality molds that meet the stringent requirements of various industries. Ultimately, a commitment to excellence in mold manufacturing processes is critical for delivering superior products and maintaining a competitive edge in the market.