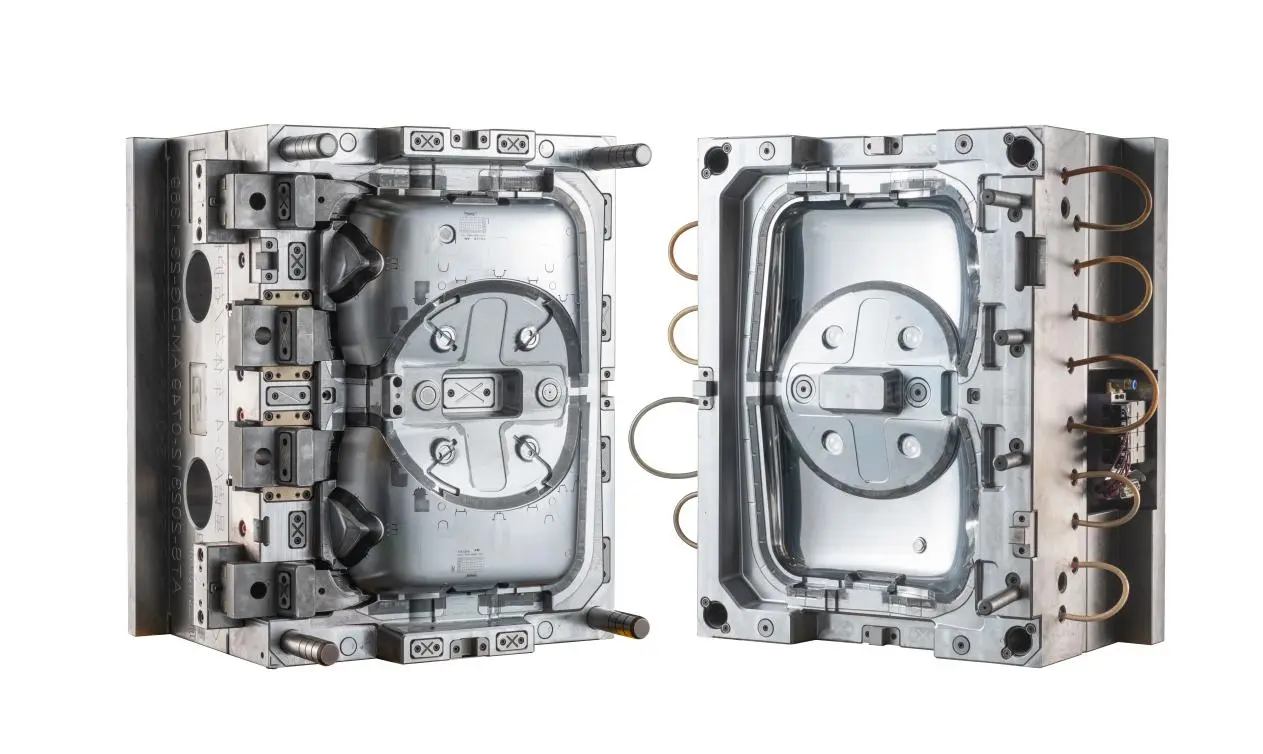

The Impact of Mold Material on Product Durability

In the world of manufacturing, the choice of mold material plays a crucial role in determining the durability and quality of the final product. The mold material directly influences various aspects such as hardness, wear resistance, mechanical properties, corrosion resistance, thermal stability, and metallurgical quality, all of which are essential to ensure the longevity and performance of the product. In this blog, we will delve into the profound impact of mold material on product durability, shedding light on the intricate relationship between material selection and the overall quality of Injection Molded products.

Hardness and Wear Resistance:

The hardness of the mold material is a fundamental indicator of its ability to withstand local deformation and wear in the working environment. High hardness is synonymous with tightly arranged internal atoms and robust intermolecular bonding forces, rendering the material to resist microscopic plastic deformation caused by external stress. This exceptional hardness allows the mold to withstand mechanical friction, shear, and impact, thereby exhibiting outstanding wear resistance and maintaining precise size and shape over an extended period. Therefore, the accuracy and stability of the mold throughout its service life are guaranteed, which directly impacting the quality and longevity of the product.

Mechanical Properties:

The mechanical properties of the mold material are pivotal in determining its suitability to withstand various forces during use. Materials with high strength and toughness, such as tool steel, are ideal for molds subjected to substantial impact loads. The ability of the material to endure high pressure and impact loads is crucial for ensuring the durability of the mold, which ultimately affects the quality and longevity of the product.

Corrosion Resistance:

Given the corrosive nature of plastic materials used in the Injection Molding process, the mold materials must exhibit excellent corrosion resistance to withstand harsh working environments. Materials with superior corrosion resistance can prolong the service life of the mold and reduce the frequency of mold replacement due to corrosion, consequently enhance the durability of the product.

Thermal Stability:

The thermal stability of the mold material significantly impacts its dimensional changes and heat transfer efficiency at elevated temperatures. Conducting tests to evaluate the thermal expansion coefficient and thermal conductivity of the material provides valuable insights for rational material selection and application. These performance tests not only aid in optimizing mold design and improving product quality but also contribute to extending the mold's lifespan, thereby enhancing the overall durability of the product.

Metallurgical Quality:

The metallurgical quality of the material, particularly high-carbon and high-alloy steel, plays a pivotal role in determining the life of the mold. Metallurgical defects in these materials can lead to mold quenching cracking and premature damage. Therefore, improving the metallurgical quality of materials is essential for enhancing the longevity of the mold, by extension, the durability of the product.

In conclusion, the choice of mold material exerts a direct and profound impact on the durability of the product. From hardness and wear resistance to mechanical properties, corrosion resistance, thermal stability, and metallurgical quality, each aspect of the mold material significantly affects the longevity and performance of injection molded products. Manufacturers and designers must meticulously consider these factors when selecting mold materials to ensure the production of durable, high-quality products that meet the stringent demands of the market.